Top China Cap Ridge Roll Forming Machine Factories: Where to Buy High-Quality Ridge Cap Sheet Roll Forming Machines

In the world of metal roofing, exactness and strength are vital. When sealing the top of a roof where panels join, a finely made ridge cap works best. This is where the cap ridge roll forming machine stands out. It turns flat metal coils into smooth, weather-proof shapes. These shapes boost both the use and look of any building. If searching for trusted places to get a high-quality ridge cap sheet roll forming machine, China’s production centers give unmatched skill. These factories focus on making machines that give steady results. They are the top choice for builders, contractors, and makers around the world.

Ridge caps are not just for show. They are the main shield against leaks, wind lift, and heat changes. A metal roof ridge cap roll forming machine makes sure these parts are shaped with tight limits. This cuts waste and shortens setup time on site. Whether looking to buy ridge cap sheet roll forming machine for a small shop or growing output, knowing the main ideas will help pick wisely.

Understanding the Ridge Cap in Roofing Systems

What Is the Ridge Cap and Why It Matters

Before diving into the tools, let’s explain what makes ridge caps key. In roofing terms, the ridge cap—sometimes called a ridge capping or roof ridge cap—rests at the highest point of the roof. It covers the ends of roof panels to form a tight water seal. This basic yet important part stops rain from entering the building shell. That could cause expensive harm over time.

Different Ridge Cap Shapes and Material Specifications

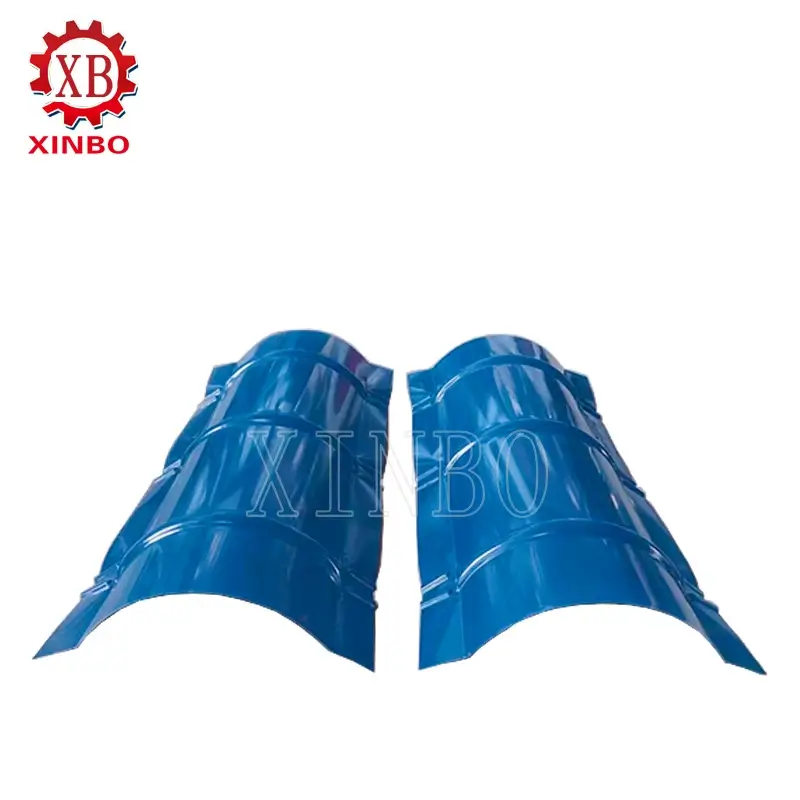

In the past, ridge caps were bent by hand or made ready off-site. But modern building needs speed. Here comes the ridge cap tile roll forming machine. It is a special tool that takes metal coils, often galvanized steel, aluminum, or color-coated sheets, through many rollers. This forms ongoing shapes. These machines can make caps in different forms: curved for nice looks, angled for trapezoidal roofs, or straight for flat uses. The outcome? Shapes that fit the roof’s slope just right. They improve air flow and lower heat build-up.

What makes a great custom metal roof ridge cap roll forming machine special is its skill to manage various specs. For example, shapes might go from 125mm to 312mm in width. Leg lengths can change from 50mm to 150mm. This flexibility is important for jobs from home houses to big warehouses. There, weather like heavy snow or strong winds sets the cap’s thickness—often 0.3mm to 0.8mm for good strength without extra weight.

How a Ridge Cap Roll Forming Machine Works: A Step-by-Step Breakdown

Coil Feeding and Alignment

At its base, a ridge capping roll forming machine works on slow bending. Flat sheet metal gets shaped bit by bit without losing strength. The step starts with a decoiler. It unwinds the metal coil, usually 3 to 5 tons in size, to feed material evenly into the machine. Then, the sheet goes through entry guides. These align it exactly. This stops wrong placement that could lead to flaws.

Progressive Roll Forming Stations

The main part is the roll forming stations. They usually number 14 to 18. Each has pairs of rollers made from strong 45# steel. These are hardened and chrome-plated for long life. These stations bend the sheet little by little into the wanted ridge shape. For a standard cap ridge roll forming machine, this might mean making a center crown with edges turned down. These hook over roof tiles firmly.

Gearbox Transmission and Power Delivery

Power comes from the transmission system. And gearbox transmission really does well here. Unlike chain-driven types, which can stretch and cause shakes, gearbox models use closed gears—often helical for smoother work—to send power from the motor, commonly 4kW to 5.5kW, straight to the rollers. This gives quieter running, less upkeep, and speeds up to 15-30m/min. It is perfect for big output.

Cutting, Safety Systems, and Output Collection

After forming, the sheet goes to a hydraulic cutting station. Servo-controlled shears cut the shape to length. This is set via PLC touchscreen for exactness within ±1mm. Safety items like quick stops and overload guards are normal in high-setup models. They keep workers safe during ongoing work. At last, a runout table or stacker gathers the done pieces. They are ready for packing.

Key Features of High-Configuration Ridge Cap Roll Forming Machines

Heavy-Duty Frame and Gearbox Transmission Advantages

When checking choices from China cap ridge roll forming machine factory outputs, look at high-configuration models. They put focus on toughness and changeability. Gearbox transmission is a key point. These systems, often with cycloidal or planetary reducers, give torque well. They handle thicker gauges without slip. Paired with a strong frame—usually welded from 40mm thick steel plates—the machine stands up to constant use.

Advanced PLC Controls and Automation

Better controls raise performance more. A PLC system, joined with a 10-inch HMI, lets real-time watch of speed, length, and thickness. Inverter-driven motors change quickly to coil differences. Sensors spot coil ends to start auto stops. This stops jams. For custom work, modular roller designs allow fast shape switches. This is vital if making both ridge cap tile types and straight caps in one place.

Energy Efficiency and Long-Term Durability

Saving power is another strong point. Top units use 20-30% less power than old chain models. This comes from better gear ratios. Noise stays below 70dB. This fits city shops. And for lasting use, parts like bearings from brands like SKF and seals promise 10+ years of work with little stop time.

These traits together make a wholesale cap ridge roll forming machine not just a tool. It is a base for steady making.

The Advantages of Gearbox Transmission in Roll Forming

Going deeper into drive tech, gearbox-driven metal roof ridge cap roll forming machine setups give clear wins over others. Old chain drives use links that wear unevenly. This leads to regular tightening and possible wrong alignment. Issues can shift shapes by up to 2mm over long runs. Gearboxes, however, close all moving parts in oil-filled cases. This cuts wear by 50% and removes grease spots that draw dirt.

The exactness gain is huge. Helical gears join at an angle. This lowers play and allows finer tweaks. This is key for shaping detailed ridge cap sheet edges that lock well with tiles. This leads to smoother work at faster speeds. It raises output from 5-7m/min in basic models to 20m/min in top ones.

Upkeep-wise, gearboxes do great with sealed builds. They need checks only every 6-12 months. Shakes are cut down. This lengthens roller life and keeps the machine’s base steady. For factories seeking high quality ridge cap sheet roll forming machine approval, this trust supports ISO-matched output. There, steady work is checked strictly.

Why Choose Top China Factories for Your Ridge Cap Needs

China’s lead in roll forming comes from its huge network of trained workers and modern plants. Top cap ridge roll forming machine factories have their own R&D. They make new ideas like AI-aided error spotting. This predicts upkeep via shake checks. These centers, mostly in areas like Hebei and Zhejiang, send out over 70% of world machines. They mix low cost with latest tech.

Getting from here means access to custom metal roof ridge cap roll forming machine fit to specs. This could be for left-hand or right-hand shapes, or links with solar mount systems. Factories stress full control. They machine rollers on CNC lathes for tiny-level exactness. This makes sure every unit comes pre-tested with video shows.

Quality checks are strict: three-step reviews cover build, test runs, and before-ship packing in 40ft containers. This lowers risks like travel harm, a usual issue in global buys. Plus, with making power hitting 500 units yearly, wait times are quick—often 25-35 days. This lets buying ridge cap sheet roll forming machine without work stops.

For wholesalers, the draw is obvious: big orders get modular designs. One frame holds many shapes via quick-swap parts. This flexibility fits varied markets, from Australia’s curved roofs to Europe’s power-saving builds.

أسئلة متكررة

What is a ridge cap roll forming machine used for?

A ridge cap roll forming machine is built to make metal ridge caps that seal the peak of roofs. It stops water entry and boosts building strength. It’s great for making custom shapes for tile or panel roofs.

Why choose a gearbox transmission for my machine?

Gearbox transmission gives better exactness, less noise, and lower upkeep than chain drives. It ensures steady forming at high speeds and lengthens machine life.

How fast can a high-quality ridge cap sheet roll forming machine operate?

Top models reach 15-30m/min, based on setup. This allows efficient big making while keeping shape exactness.

Can I customize a metal roof ridge cap roll forming machine?

Yes, custom choices include shape sizes, roller numbers, and add-ons like punching stations. They are fit to certain roofing needs.

What materials work best with these machines?

Galvanized steel, aluminum, and color-coated coils from 0.3mm to 0.8mm thickness do best. They offer lasting use and rust fight.

Ready to Elevate Your Roofing Production? Contact XINBO Today

Change the workflow with a modern cap ridge roll forming machine from XINBO. Here, high-configuration quality meets gearbox-driven trust. As a focused manufacturer since 2014, roll form machines are made that give exactness and speed for world builders.

The own workshop has advanced CNC machining centers. A skilled team of professional engineers, designers, producers, and workers makes sure every machine—from standard models to full custom designs—is built with careful focus.

Get a personal quote now—email at serena@cnxinbo.net or call +86-15075193569. The next high-quality ridge cap production line starts here!

مشاركات ذات صلة

الإسبانية

الإسبانية روسيا

روسيا