Best IBR Roof Panel Roll Forming Machine for High-Quality Roofing Sheets

In today’s fast-changing construction world, builders face growing demands to create roofing options that are strong, long-lasting, and nice to look at. The IBR roof panel roll forming machine is a game-changer. It helps make top-notch Inverted Box Rib (IBR) roofing panels from flat metal rolls. These machines are super important for getting steady results, whether for small home projects or big factory builds.

What Is An IBR Roof Panel Roll Forming Machine?

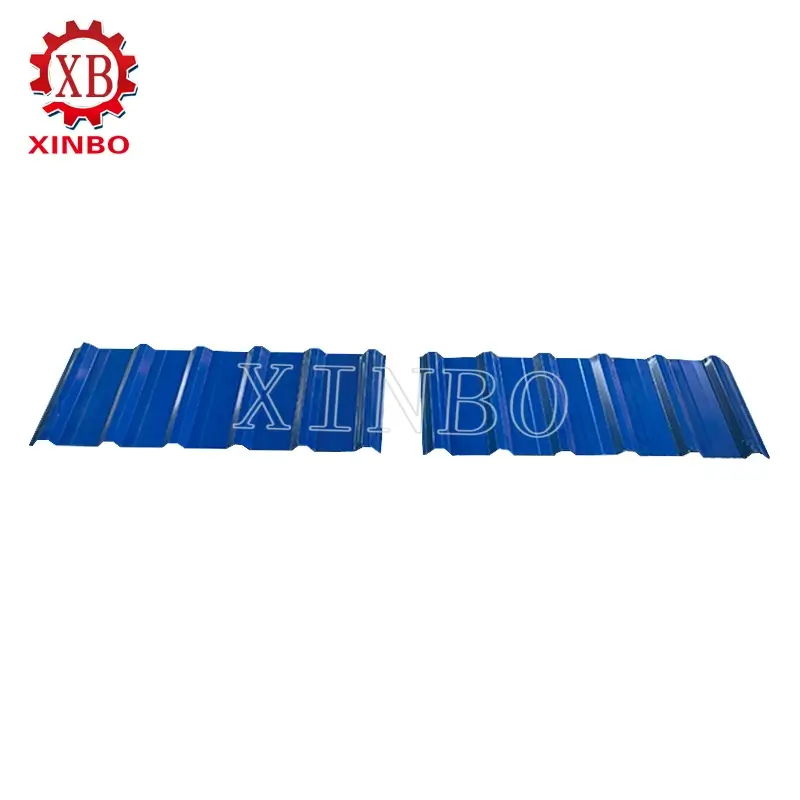

An IBR roof panel roll forming machine is a special kind of factory tool made to craft Inverted Box Rib (IBR) roofing sheets. These sheets have a distinct trapezoid shape. The pattern of high and low lines in the IBR design gives great strength and helps water run off easily. This makes them a perfect fit for places with tough weather, like many areas in Africa.

Defining Features Of IBR Roof Panel Roll Forming Machines

Material Flexibility: Works with galvanized steel, aluminum, or zinc-coated rolls, usually between 0.4mm and 0.8mm thick.

Exact Automation: Uses Programmable Logic Controller (PLC) systems to manage panel sizes and speed with pinpoint accuracy.

Long-Lasting Build: Made from tough stuff to keep going for over 20 years if cared for well.

Tailored Results: Settings can be changed for panel width, length, and shape to match specific needs.

These machines cut out human mistakes by handling bending and cutting on their own. This saves material and keeps everything looking the same.

How Does An IBR Roof Panel Roll Forming Machine Work?

The smooth and automatic process of an IBR roof panel roll forming machine is what makes it so good. It turns plain metal rolls into finished roofing panels with amazing accuracy.

Step-by-Step Operational Process

- Coil Loading and Uncoiling: First, a metal roll gets placed on the uncoiler. It can hold many tons, so production keeps going without constant reloads.

- Feeding and Alignment: Special rollers and guides straighten the metal strip. This stops any mix-ups and ensures perfect panels.

- Roll Forming: The strip moves through 12 to 22 roller spots. Each one slowly shapes the metal into the IBR design.

- Cutting to Length: A strong hydraulic cutter slices the shaped panels to exact sizes. It’s super precise, with errors as small as ±1mm, thanks to encoder help.

- Collection and Stacking: Done panels gather on a runout table or auto-stacker. This makes handling after production much easier.

Advanced Operational Features

- PLC Automation: Easy touch-screen controls let workers set things like length, number, and speed, which can go up to 20m/min or more.

- Fast Production: Some newer models hit speeds of 30-45m/min when lots of panels are needed.

- Safety Features: Emergency stop buttons and safety covers keep workers safe.

Key Components Of A High-Quality IBR Roof Panel Roll Forming Machine

Every part plays a big role in how well the machine works:

- Uncoiler: Holds heavy rolls, up to 5–10 tons, for a steady material supply.

- Feeding and Guiding System: Has entry guides and rollers to keep the strip straight.

- Roll Forming Stations: Made of 15–20 strong steel rollers, crafted by CNC machines and coated with chrome.

- Hydraulic Cutting Unit: Comes with sharp blades and encoder controls for clean, exact cuts.

- PLC Control System: Offers a touch-screen for both automatic and manual settings.

- Runout Table or Auto-Stacker: Gathers finished panels neatly, with extra automation options.

Benefits Of Using IBR Roof Panel Roll Forming Machines

Strong Build: The IBR box rib shape allows wide coverage with little extra support. It’s great for low-angle roofs and heavy weights.

Quick Output: Can make up to 20m/min, producing thousands of meters of sheets in one shift.

Budget-Friendly: Automation cuts down on worker costs and reduces waste with spot-on forming and cutting.

Weather-Proof: Panels have coatings to fight rust, lasting long in rough conditions like heavy rain or strong sun.

Eco-Friendly: Uses metals that can be reused and runs on low energy, fitting green building goals.

Applications Of IBR Roofing Sheets

Roofing sheets from an IBR roof panel roll forming machine are super useful. They work well for:

- Residential buildings

- Almacenes

- Commercial centers

- Farm buildings like barns

- Renewable energy setups for solar panels

- Basic infrastructure like temporary shelters

Customization Options For Enhanced Flexibility

Today’s building needs call for options. That’s why customizing is so important:

Changeable Roller Setups: Make different rib heights and widths, like 686mm or 890mm effective widths.

Material Choices: Work with metals such as galvanized steel or stainless steel for unique jobs.

Speed Settings: Pick speeds from 10–45m/min based on how much you need.

Double-Layer Feature: Switch between shapes like corrugated sheets.

Extra Tools: Add units for punching or embossing.

Maintenance And Troubleshooting For Optimal Performance

To keep things running smoothly for years:

Maintenance Checklist

Daily Check: Wipe down rollers and look for wear.

Weekly Task: Grease moving parts.

Monthly Job: Look over hydraulic systems.

Every Three Months: Check electrical bits.

Yearly Care: Get a pro to service it.

Solución de problemas comunes

Wavy or Bent Panels: Fix the feeding setup.

Cuts Not Even? Sharpen the blades. Machine Too Hot? Check the motor’s load.

Choosing A Reliable IBR Roof Panel Roll Forming Machine Supplier: Instant Quote from XinBo

When looking for an IBR roof panel roll forming machine supplier, make sure to check their background, ability to customize, certifications, help services, and how fast they deliver.

XinBo started in 2015, is a trusted supplier of various metal roof sheet roll forming machines. We happily accept ODM and OEM orders. Our machines have reached places like Europe, the Middle East, and Africa. Our motto is “dedicated, united, innovative.” We promise top-quality products to our customers. Feel free to ask us anything; we’ll get back to you within 24 hours!

XinBo provides CE-certified machines made just for you, along with quick after-sales help—making them a solid choice for your production needs.

Preguntas frecuentes

Q1: What materials work in an IBR roll forming machine?

A: Galvanized steel, aluminum, and zinc-coated rolls, usually 0.4mm–0.8mm thick.

Q2: How quick can these machines make panels?

A: Regular models go up to 20m/min, while fancier ones can hit 45m/min.

Q3: Can one machine make different shapes?

A: Yes—special machines can have double-layer setups for different outputs.

Q4: How long do these machines usually last?

A: With good care, they can keep working for over 20 years.

Q5: Does XinBo help with setup?

A: Yes—XinBo offers setup guidance and ongoing tech support.

Publicaciones relacionadas

Buena calidad

XinBo máquina que hace CO. LTD es un fabricante profesional y exportador en la máquina de formación de rollos,

Ver más→

Español

Español Rusia

Rusia