Choosing the Best Glazed Roof Tile Roll Forming Machine: A Guide to China Manufacturers

In the changing world of building and roofing, the need for strong, nice-looking materials has grown a lot. The glazed roof tile roll forming machine stands out as a tool of exact crafting. It turns simple metal coils into graceful, step-shaped tiles that look like old clay styles. These machines play a key role in making roof panel step tile profiles. They mix old charm with new speed. As building jobs around the world focus on green ways and looks, picking the right glazed roof tile roll forming machine matters a great deal. This helps makers stay ahead. China leads in this tech. It gives many choices from skilled factories. These focus on high-configuration setups with strong gearbox transmissions for top work.

People look into uses of glazed tile roofing machines. Or they want an automated glazed tile roofing forming machine that works well and handles many tasks. Here, useful tips appear. By the finish, one can pick a custom glazed roof tile roll forming machine that fits production wants.

Understanding the Glazed Roof Tile Roll Forming Machine

Core Process of Metal Tile Formation

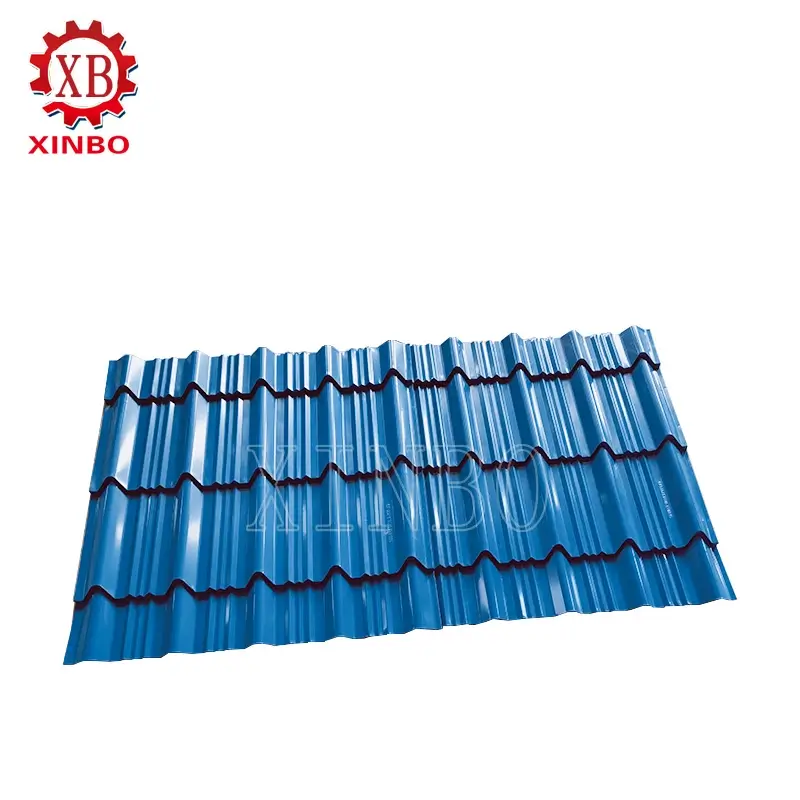

The glazed roof tile roll forming machine serves as special gear. It shapes metal sheets non-stop into profiled tiles with a shiny, stepped look. Metal versions differ from old clay or concrete tiles. They come from pre-painted galvanized steel (PPGI) or galvalume coils. These prove light, rust-proof, and fast to set up. The steps start when a coil enters the machine. The coil stays 0.3mm to 0.8mm thick. It moves through rollers. These form the sheet into waves or steps bit by bit. Then, hydraulic pressing adds depth. Cutting sets the length.

High-Configuration Design Excellence

Top models shine with high-configuration design. They use advanced parts like PLC (Programmable Logic Controller) systems for auto control. Gearbox transmission sends power. Premium kinds blend servo motors, touch screens, and live checks. This improves each step. It keeps quality steady. And it cuts need for workers.

Superior Gearbox Transmission Mechanism

Gearbox transmission stands out. It applies closed gear units. These move force from the motor to rollers. This brings smooth, quiet runs. Speeds hit 10-15 meters per minute. Chain systems wear quick. They add shakes that hurt tile exactness. A good gearbox cuts care needs. It lengthens machine life. This suits big output.

Customization Options for Versatile Profiles

These machines fit many needs. China manufacturers give customized glazed tile roof sheet roll forming machines. They match set profiles. Examples include adjustable step depths of 200-300mm. Or widths to 1250mm. A roof glazed tile roll forming machine may add servo motors for exact feed. This holds errors to ±0.5mm. Such tightness aids smooth roof fits.

Key Features and Technical Specifications

When checking choices, seek machines with high configurations. They stress trust and output. A leading glazed roof tile roll forming machine often has:

· Decoiler and Feeding System: Hydraulic or manual decoilers take coils to 10 tons. Leveling tools fix sheet flat issues. Auto kinds use sensors for easy feed. This drops stop time.

· Roll Forming Stations: 18-24 stations use high-grade 45# steel. They get quenched for hardness at HRC 58-62. Rollers gain chrome to fight wear. They make tiles with even waves. These copy the bright finish of old glazed ceramics.

· Hydraulic Pressing Unit: This forms the core of step tile work. It pushes to 20 tons for set steps. Steps aid water flow and strength. In high-config models, it joins after forming for speed.

· Gearbox Transmission: This marks power-heavy tasks. Chain drives differ. Gearboxes spread load even on shafts like 75mm diameter. They cut energy loss by 15-20%. Noise stays under 70dB. This fits long runs of 8-12 hours with no heat issues.

· Cutting and Stacking: Hydraulic shears cut tiles to length up to 12m. Burrs stay low. Auto stackers manage output. This saves work.

Tech details change. But top units from China glazed tile roof sheet roll forming machine factories show yields of 230-350 MPa on materials. Speeds reach 8-10 m/min. Power sits at 15-22 kW. Safety items like quick stops and guards meet CE and ISO rules. For many uses, seek models with fast-change tools. One machine turns into a multi-task tool.

Applications of Glazed Tile Roofing Machines

Products from these machines work in many areas. This shows the range of applications of glazed tile roofing machines. They serve home roofing first. Stepped design brings a Mediterranean touch to villas and houses. It boosts drainage. Leaks drop. In business spots like hotels and stores, tiles resist fire to Class A1. They hold against 12-level winds. This fits big roofs.

An automated glazed tile roofing forming machine brings gains to factory and storage builds. It makes sheets for wide spaces with few joins. Light weight hits 5kg/m². Clay tiles reach 40kg/m². This eases move and set up. Work costs fall 30%. In farm sheds, rust-proof coat handles tough settings. Life spans over 20 years.

New uses cover solar panel holds. Tile strength backs photo arrays with no extra frames. Custom glazed roof tile roll forming machines allow bent or cone shapes for dome builds in resorts. In all, these machines open high-end roofing. They give fast, flexible answers. They balance looks, strength, and price.

Benefits of High-Configuration Gearbox-Driven Machines

Buying a glazed roof tile roll forming machine with gearbox transmission brings clear gains. Precision comes first. The firm drive keeps roller match steady. Tiles gain perfect evenness. They lock well on site. Waste stays under 2%. Fix calls drop.

Speed marks another strength. High-config kinds auto-handle 90% of steps. From coil load to stack. Output rises to 5,000-7,000m per shift. Gearbox speed saves energy 10-15% over old chain types. Lasting power follows. Sealed gearboxes block dust and wet. This fits damp areas. MTBF tops 10,000 hours.

Green wise, machines aid eco ways. They use recycle metals. Scrap stays low. For makers, ROI proves strong. A mid unit pays back in 12-18 months via more work and high tile prices. In short, a customized glazed tile roof sheet roll forming machine from a solid factory acts as more than gear. It serves as a key step up for growth.

Choosing the Right Machine from China Manufacturers

Finding China glazed tile roof sheet roll forming machine manufacturers needs a smart plan. Begin with time in field. Pick factories with 10+ years in roll forming. They hold own R&D for new ideas like module builds. Check certs—CE, ISO 9001. Ask for case reports from world sets.

Custom fit matters. Talk needs like profile details such as 0.4-0.6mm thickness match. And link to current lines. Good makers give CAD plans and test parts in 2-4 weeks. Costs sit at $25,000-$60,000. Config level sways it. Gearbox types ask 20% more. But they give lasting worth.

Check post-sale help. Seek abroad training, 24-month promises, and part stock. View factories by video or live. Gauge quality steps like CNC work for rollers. Last, favor those with full help from plan to ship in 40ft boxes. This makes sure the glazed tile roof sheet roll forming machine for sale comes set to run.

Preguntas frecuentes

What materials are best for a glazed roof tile roll forming machine?

PPGI or PPGL coils in 0.3-0.8mm thickness work best. They give rust fight and bright ends for tiles that last.

How fast does a high-config glazed roof tile roll forming machine operate?

Speeds hit 8-15 m/min. They make up to 7,000m per shift. This rests on profile hard and auto level.

Can I customize a roof glazed tile roll forming machine for specific step depths?

Yes. Most manufacturers tweak pressing units for depths from 150-350mm. Quick-change tools add range.

What makes gearbox transmission superior in these machines?

It gives smoother power move, less noise, and more lasting than chain drives. This fits non-stop big runs.

Are these machines suitable for curved roofing applications?

Absolutely. Custom models back bending for arches or cones. This widens uses in build projects.

Ready to Elevate Your Production? Contact XINBO Today

Do not take old gear when a high-config glazed roof tile roll forming machine can boost output. XINBO acts as a trusted China manufacturer since 2014. It focuses on new, gearbox-driven answers fit to needs.

Get Your Free Quote Now – Email specs or call +86-+8615075193569 to begin the ideal machine. Craft roofing answers that last—contact XINBO today!

Publicaciones relacionadas

Buena calidad

XinBo máquina que hace CO. LTD es un fabricante profesional y exportador en la máquina de formación de rollos,

Ver más→

Español

Español Rusia

Rusia