High‑Speed 60 m/min Roof Panel Machine for Fast, Efficient, Time‑Saving Roofing Production

In today’s construction and steel‑structure industry, the demand for large‑scale, high‑output metal roofing production continues to grow. For projects requiring massive roof sheets, a High‑Speed 60 m/min Roof Panel Machine becomes indispensable.

What is a Roof Panel Roll‑Forming Machine?

“Roll forming” is a manufacturing process where a long strip of sheet metal (typically from a steel coil) is continuously bent through a succession of rollers to achieve a desired cross‑sectional profile.

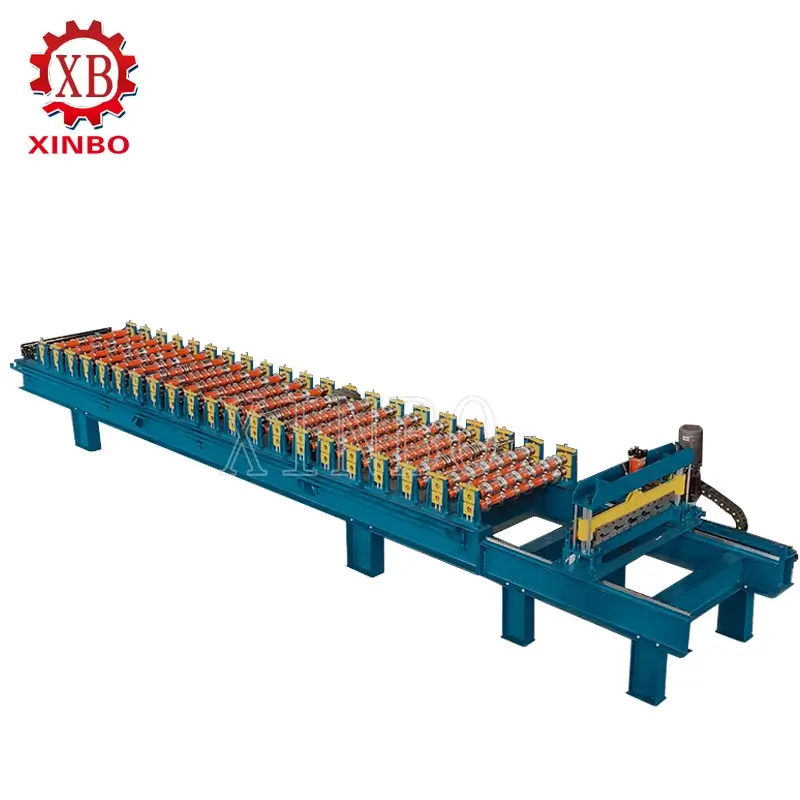

Una máquina de formación de rodillos de panel de techo — also known as a metal roof sheet machine — applies this technique to produce roofing or wall panels. The line typically includes components such as a decoiler (to unroll the steel coil), a guiding/leveling system, multiple roll‑forming stands, a cutting system, and an output stacker or conveyor.

While older or simpler machines may run at modest speeds (e.g. 15–25 m/min), modern high‑speed fully automatic machines can reach up to 60 m/min under optimal conditions.

The Core Advantages of a High‑Speed Roof Panel Machine

⚡ Massive Throughput — Speed and Efficiency

A machine capable of 60 m/min represents a dramatic leap over traditional roll forming lines. At this speed, a factory can produce hundreds or even thousands of linear meters of roofing panel per hour, enabling massive output for large‑scale projects. According to manufacturers, roof panel roll forming machines rated “50–60 m/min” offer precisely that increased output capacity for efficient roofing sheet manufacturing.

Advantages include:

Large‑volume orders: Perfect for industrial warehouses, commercial facilities, or large housing developments needing hundreds or thousands of square meters of roofing.

Shortened project timelines: Faster production reduces lead times — clients get metal panels quicker, speeding up construction schedules.

Reduced labor costs: Automation reduces manual handling and labor need; fewer operators can manage the line.

Automation + Stability = Consistent Quality

Modern “efficient metal roofing forming machines” are often fully automated: from decoiling → guiding → roll forming → cutting → stacking. Many implement PLC control, servo or hydraulic cutting systems, and auto‑stacking/outfeeding mechanisms.

This automated flow offers:

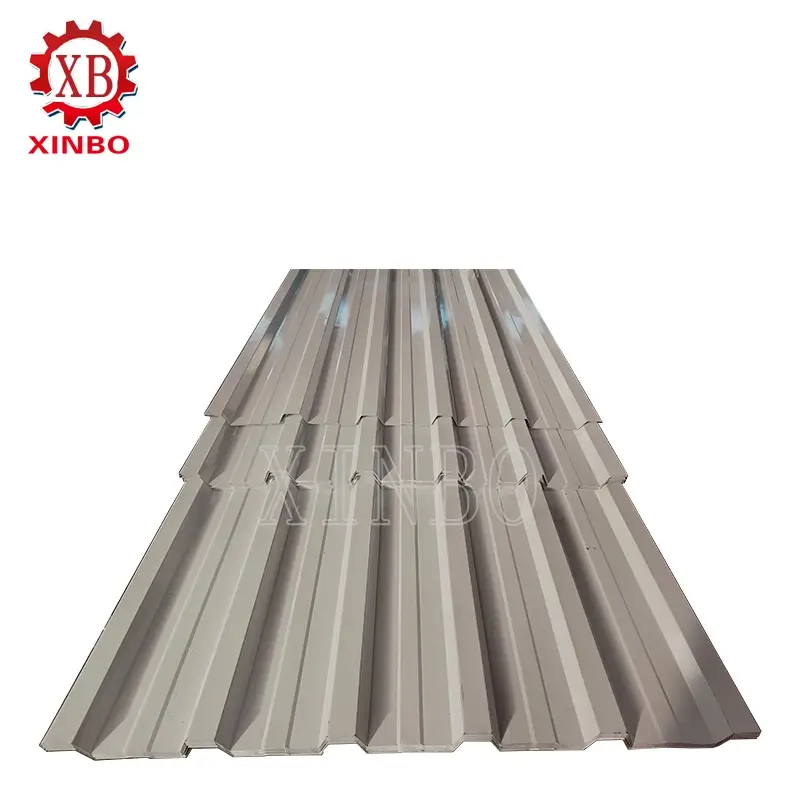

Consistent panel profiles: Every panel has identical shape, dimension, and quality — critical for seamless assembly and weather‑tight roofing.

Accurate cutting and length control: With servo or flying‑shear cutting, length tolerance can be very tight (e.g. ±1–2 mm), minimizing scrap and ensuring easy installation.

Reduced waste & better material utilization: Precise forming and cutting reduces off‑cuts and scrap. Many roll forming operations report minimal waste compared to manual or press‑based methods.

Versatility & Customization

A high-efficiency metal roofing forming machine often supports a variety of metal types and thicknesses — such as galvanized steel, pre‑painted steel (PPGI), aluminum, and other coated or coated‑steel coils. Typical sheet thickness compatibility ranges from around 0.3 mm to 0.8 mm or more, depending on machine configuration.

Moreover, many machines allow interchangeable tooling or a quick-change “cassette” system so that different panel profiles (corrugated, trapezoidal, standing‑seam, etc.) can be produced on the same line.

Why “High‑Speed + Fully Automatic + High Efficiency” Is Critical Now

Several market trends make high-speed, automated roof panel forming machines highly desirable:

Rising demand for industrial & commercial steel roofing: As more factories, warehouses, and large-scale projects are built, demand for metal roofing panels skyrockets. Traditional methods and slower machines often fall short in meeting volume requirement.

Speed & labor cost pressures: Labor rates, freight costs, and lead-time pressures have all risen. Automated high-speed production dramatically cuts both time and manpower per square meter of roofing produced.

Quality and consistency expectations: Architects and contractors demand consistent, precise panels to ensure seamless installation, leak‑resistant seams, and uniform aesthetics. Automation reduces human error and improves first-pass yield.

Economic scalability for manufacturers: A single “metal roof machines increased efficiency and speed” line — rather than multiple manual or semi-manual lines — reduces overhead, simplifies maintenance and staffing, and delivers predictable output.

Typical Technical Setup of a High‑Speed Roof Panel Roll‑Forming Line

Here’s what you typically find in a top‑end high-speed line:

Decoiler / Uncoiler — loads and feeds steel coils automatically.

Guiding & Leveling System — ensures the incoming strip is aligned and flat.

Roll Forming Stations — often 15–22 stands, each gradually bending the metal to the final profile to avoid stress or deformation.

Drive & Control System — heavy‑duty steel frame, chain or gear drive, frequency inverter (VFD) or servo‑driven motor, PLC + touchscreen.

Sistema de corte — servo or hydraulic flying shear or post‑cut, cutting at full line speed without stopping; ensures precision length and reduces scrap.

Automatic Stacker / Outfeed Table — finished panels are automatically stacked or bundled for packaging or further handling.

This integrated, continuous process embodies what people refer to when discussing a “high‑speed roofing machine: efficient and precise roofing” — a system that saves time, reduces labor, and delivers consistent, high-quality metal roof panels.

Who Should Consider a High‑Speed Metal Roofing Forming Machine?

Ideal Scenarios

Large industrial or commercial roofing projects — warehouses, factories, large residential complexes, commercial centers: these require big volumes of roofing sheets with fast turnaround.

Roofing manufacturers with high output demand — businesses producing large quantities of metal roofing sheets regularly will benefit most from the reduced per‑unit cost, speed, and automation.

Businesses seeking cost-efficiency and scalability — fewer workers, lower waste, less manual labor, and higher throughput.

Projects requiring multiple profile types or custom profiles — thanks to customizable tooling or quick-change cassettes, a single machine can produce different panel types according to demand.

When a High-Speed Machine May Not Be Necessary

Small-scale projects or occasional production runs — in such cases, a simpler, slower roll forming machine (e.g. 20–30 m/min) with lower cost may be sufficient.

Very low volume or niche profiles that are used rarely — the cost and maintenance of a high-speed line might not be justified.

When flexibility and mobility are key (e.g. onsite forming, small batches) — a portable or semi-automatic roll former could suffice, though with lower speed/output.

How to Choose the Right Roof Panel Roll‑Forming Machine

When selecting a machine — whether investing in a “high-speed 60m/min roof panel machine” or a more modest line — you should carefully evaluate:

| Factor | What to Check / Consider |

|---|---|

| Line Speed | For large volume needs: 40–60 m/min or above. For small or occasional jobs: 15–25 m/min may suffice. |

| Nivel de automatización | Full automation (decoiler → forming → cutting → stacking) reduces labor, speeds up production, improves safety, and ensures uniform output. |

| Compatibilidad del material | Make sure the machine supports the materials you use (e.g. galvanized, pre‑painted, aluminum) and the thickness range required (commonly 0.3–0.8 mm or per specification). |

| Profile Flexibility | If you need different roofing profiles (corrugated, trapezoidal, standing seam, etc.), choose a machine with interchangeable tooling or quick‑change molds. |

| Cutting & Tolerance Precision | Servo/flying shear or hydraulic cutters with tight tolerance (e.g. ±1–2 mm) ensure panels fit easily on site and reduce waste. |

| Durability & Maintenance | Robust frame, quality roll tooling (e.g. hardened/chrome‑coated rollers), reliable drive and control systems — all matter for long-term, heavy-duty operation. |

Carefully checking these elements will help ensure that the investment in a high-efficiency metal roofing forming machine yields long-term benefits rather than becoming a costly misfit.

Challenges & Considerations

While there are major advantages, a few challenges should be considered:

Higher upfront investment — high-speed, fully automated lines cost more than simple manual or semi-automatic roll formers.

Maintenance and technical expertise — to maintain precision and avoid downtime, you need trained operators, regular maintenance, and possibly spare parts.

Profile and setup time for multiple profiles — changing panel profiles may require tooling change or cassette swap, which adds to setup time (unless machine supports quick-change tooling).

Material & coil quality matters — poor coil quality (e.g. uneven thickness, low coating quality) can lead to defects, even on a high-end machine.

Space & infrastructure requirements — high-speed lines often require sturdy foundation, stable power supply, considerable floor space, and safety measures for automation.

Nevertheless, for manufacturers with substantial output demand, these trade‑offs are often outweighed by the gains in speed, consistency and cost‑effectiveness.

Conclusión

If you’re looking for a solution that delivers large‑volume metal roofing sheet production with maximum output, high precision, low labor dependency, and minimal waste, then the High‑Speed 60 m/min Roof Panel Machine represents a state-of-the-art, cost‑effective investment. Its combination of speed, automation, versatility, and consistent quality makes it ideal for modern roofing manufacturers and large-scale projects.

Discover the High-Speed 60m/min Roof Panel Machine – Contact XINBO Today

Ready to quadruple your roofing panel output while slashing lead times? XINBO, a specialist with over 20 years in precision roll forming, operates a 35,000 m² state-of-the-art facility equipped with German CNC machining centers and Japanese robotic welding lines. Our in-house R&D team of 28 engineers continuously refines high-speed drive systems and quick-change tooling to keep your production ahead of market demands.

For tailored line layouts, on-site commissioning, or flexible financing plans, reach our service team to submit your project details. Contact XINBO now to schedule a live virtual demo and unlock unmatched manufacturing efficiency.

Publicaciones relacionadas

Buena calidad

XinBo máquina que hace CO. LTD es un fabricante profesional y exportador en la máquina de formación de rollos,

Ver más→

Español

Español Rusia

Rusia