C Channel Steel Roll Forming Machine for Ceiling Systems: Benefits and Applications

In today’s fast-changing world of building design and interior work, suspended ceiling systems have become very common. They help create spaces that look nice and work well. These systems hide electrical wires, water pipes, and air ducts. They also make rooms quieter, safer from fire, and better at keeping warmth inside. The main equipment that produces strong and uniform ceiling frames is the C channel steel rolvormende machine. This machine takes flat steel coils and turns them into sturdy C-shaped sections. Builders use these sections as furring channels, main runners, and cross tees.

Lightweight steel frames are now needed more than ever. People want greener buildings, and cities keep growing fast. A reliable C channel roll forming machine lets makers meet tough industry rules. It also helps them produce parts quicker and with less trouble.

This guide talks about how C channel forming really works. It explains why the machine matters so much for ceiling projects. Readers can see the clear benefits it offers. Contractors, metal shops, and material suppliers can find out how a long service life C channel roll making machine functions. This information helps everyone make smart choices, lower expenses, and get better results on every job.

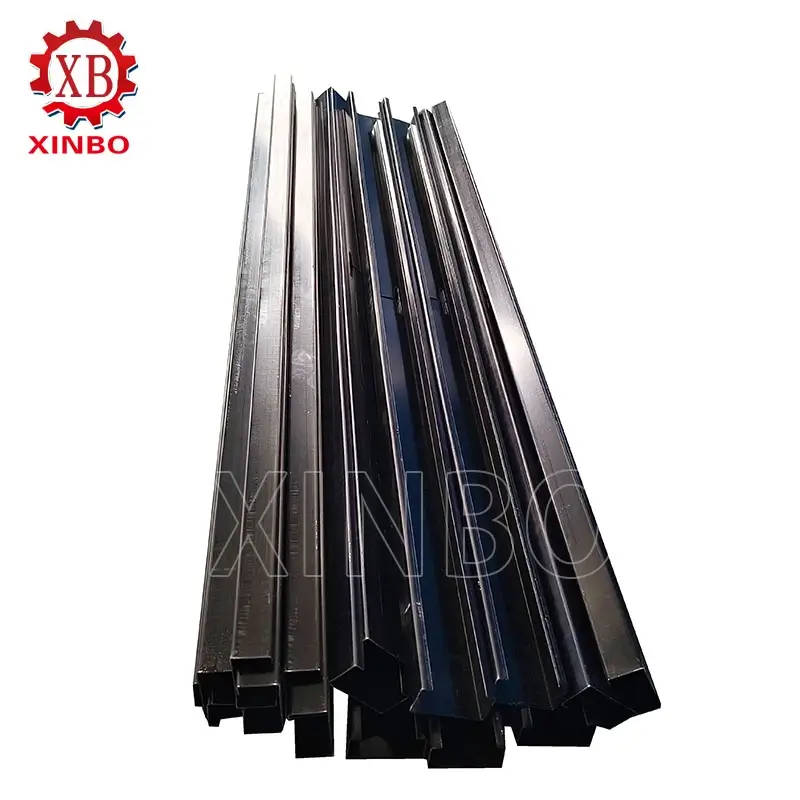

The Fundamentals of C Channel Steel Roll Forming for Ceiling Profiles

img.C Channel Steel Roll Forming for Ceiling.webp

Roll forming is a cold-bending process. It lets factories turn out large numbers of complex metal shapes without stopping. Almost no material gets wasted. A C channel steel roll forming machine gradually bends galvanized or pre-painted steel strips. Thickness normally ranges from 0.4mm to 1.2mm. The result is accurate C profiles. Flanges stay between 20-50mm, and webs measure 50-150mm.

When compared to stamping or extrusion, roll forming shares the bending effort across many stations. Each station uses strong rollers made of Cr12MoV steel, HRC 58-62. Finished parts stay inside ±0.5mm tolerance.

For ceiling work, these machines create lightweight keels. The pieces snap together quickly to form grids. They support gypsum boards, acoustic tiles, or LED panels without any trouble.

Key Specifications for Ceiling Applications

- Decoiler capacity: 5–10 tons, coil width up to 300mm

- Servo-driven punching for hanger holes (pre- or post-forming)

- Hydraulic flying shears for burr-free cuts at speeds of 20–40m/min

- PLC/HMI control systems for storing multiple profile recipes

- Modular roll cassettes for quick flange adjustments

With these features, a decorative C channel roll forming machine changes raw steel into ready frames. The profiles fit together perfectly. Ceilings end up straight and solid.

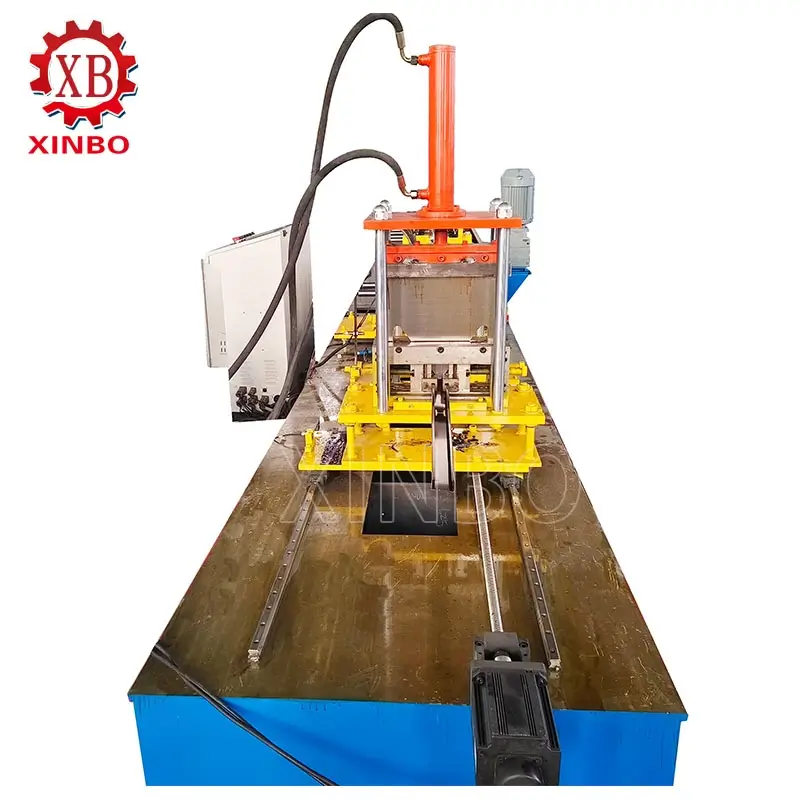

Key Components of a C Channel Forming Machine

A skilled C channel forming machine manufacturer puts together strong mechanical parts and clever digital controls. The process moves step by step:

- Hydraulische Uncoiler– Holds coils (ID 450–650mm) firmly and feeds steel with steady tension (0.2–0.5% elongation).

- Roller Straightener– Removes bends and wavy edges so the strip enters the forming area completely flat.

- Forming Stations– Paired rollers on Ø70–80mm shafts bend the web first, then the flanges, and finally the small lips for added stiffness. Strong gearbox or chain drives (15–22kW) spread power evenly so nothing slips.

- Servo Punch Presses– Deliver up to 20-ton force to punch oval slots or round holes for hanging clips. Encoders keep every hole in the right place.

- Snijsysteem– Hydraulic flying shear cuts lengths from 1–6m while the line keeps running.

- Run-Out Table and Stackers– Soft PU rollers protect the surface. Optional stackers bundle pieces neatly for packing.

- Veiligheidskenmerken– CE-compliant guards, light curtains, emergency stops, and energy-saving IE3 motors that cut power use by 20–30%.

- Optional Ceiling-Specific Enhancements– Embossing for better grip, pre-notching for easy corner bends, and designs that meet seismic rules.

How a C Channel Roll Forming Machine Operates

- Coil Loading– Workers set the coil on the hydraulic uncoiler.

- Straightening– The strip passes through 7–11 rollers and comes out flat and smooth.

- Forming– Bending takes place bit by bit across several roller stations.

- Punching– Quick servo punches add slots and holes in exactly the right spots.

- Snijden– The flying shear cuts profiles to length without stopping the line.

- Handling– Tables and stackers catch the finished pieces gently and keep the surface flawless.

Solid mechanics and modern controls work side by side. The outcome is precise parts, fast output, and very little need for hands-on work.

Benefits of Using a High Quality C Channel Roll Forming Machine in Ceiling Production

- Precisie– CNC-ground rollers and encoder feedback create perfect shapes every time. Workers on site save up to 40% of adjustment time.

- Efficiëntie– Non-stop running keeps waste under 2%. One or two operators can run the line 24/7.

- Duurzaamheid– Tough parts and sealed bearings last 10–15 years. IoT sensors give early warnings before breakdowns.

- Kostenbesparing– Making profiles in-house costs $0.50–1.00 per meter instead of $1.50+ for bought ones.

- Sustainability– Steel is recyclable, the process uses little energy, and lighter frames help earn LEED points while lowering transport weight.

- Veelzijdigheid– One machine handles many ceiling types, sound control, earthquake zones, and lighting layouts.

Applications in Ceiling Systems and Beyond

Ceiling Systems

- Main tees: placed every 1.2m and hung from roof joists

- Cross tees: 0.6m pieces that form 1.2×0.6m bays

- Furring channels: level uneven surfaces for plasterboard or mineral wool

- Acoustic optimization: deeper channels reduce noise by 40dB

Other Applications

- Partitions: C studs up to 92mm

- Solar racking: slotted strut channels

- Shelving: lipped edges spread weight

- HVAC: C channels hold ducts and reduce vibration

- Automotive: strengthen vehicle frames

A single machine serves many fields, so the return on investment comes quickly.

Maintenance Tips for a Long Service Life C Channel Roll Making Machine

Daily: Clean rollers and check belts.

Weekly: Lubricate chains and gears; check alignment (±0.02mm). Monthly: Tighten bolts (M12, 50Nm); recalibrate encoders via PLC.

Quarterly: Replace hydraulic oil (ISO VG46); grind rollers if runout exceeds 0.05mm.

Annual: Full shaft inspection; update software for better fault records.

Keep shop humidity below 60% RH and train operators properly. Corrosion and overload stay away. Rollers then last 1–2 million meters, and downtime stays under 5%.

Emerging Trends and Future Outlook

- AI cameras detect flaws as small as 0.1mm

- Smart controls adapt to different steel batches automatically

- Hybrid lines mix roll forming with 3D printing for quick prototypes

- Eco-friendly alloys made from recycled aluminum

- Full servo upgrades expected to boost efficiency another 20% by 2030

C channel roll forming machines will stay essential for smart, strong buildings.

Conclusie

The C channel steel roll forming machine sits at the heart of modern ceiling systems. It delivers accuracy, speed, and lasting strength. Perfect grids come together fast, and sturdy supports work in many projects. Companies save money, improve quality, and support green goals.

Fabricators and manufacturers who adopt this technology open doors to bigger opportunities around the world.

Veelgestelde vragen

Q1: What materials are best suited for ceiling production?

Galvanized steel (G60–G90) or pre-painted coils (0.4–1.0mm). Aluminum is excellent where weight and moisture are concerns.

Q2: How does a high quality machine improve installation efficiency?

Uniform shapes and exact hole spacing cut assembly time by 30–40%. Ceilings stay level without extra shims.

Q3: What speeds can a best C channel roll forming machine achieve? 20–40m/min for standard profiles; custom lines reach 50m/min.

Q4: Are customization options available?

Yes. Modular designs allow easy flange/web changes (50–150mm) and added punching or embossing for special grids.

Q5: How to ensure long service life?

Follow regular lubrication, alignment checks, oil changes, and use hardened rollers (HRC 60+).

Q6: Can one machine produce profiles for ceilings and partitions?

Yes. Fast tooling changes let the same line make C studs and furring channels.

Discover Precision C Channel Solutions with XINBO

Boost ceiling production quality with XINBO’s C channel roll forming machines. Check the products on the XINBO Products page, ask for custom advice through XINBO Service, or learn the company story at About XINBO. Contact XINBO today for a free quote and upgrade the whole production process right away!

Gerelateerde berichten

Goede kwaliteit

XinBo-machine die CO. LTD maakt is een professionele fabrikant en exporteur in rolvormende machine,

Bekijk meer→

Spaans

Spaans Rusland

Rusland