China U Channel Roll Forming Machine Manufacturer | OEM & Custom Factory

In the field of metal working, the u channel roll forming machine serves as a vital tool for creating accurate U-shaped sections needed in today’s building and factory uses. Whether people look for an OEM u channel roll forming machine, a dependable China u channel roll forming machine, or a fitted custom u channel roll forming machine, grasping the details of this method stays important to improve your making process.

As top u channel rolvormende machine factories and u channel roll forming machine manufacturers keep bringing new ideas, the need for wholesale u channel roll forming machine choices has grown quickly. This rise comes from the want for quick, low-cost production.

This full guide explores the ideas, steps, and uses of U channel roll forming machines. It gives skilled tips to aid you choose wisely for your work.

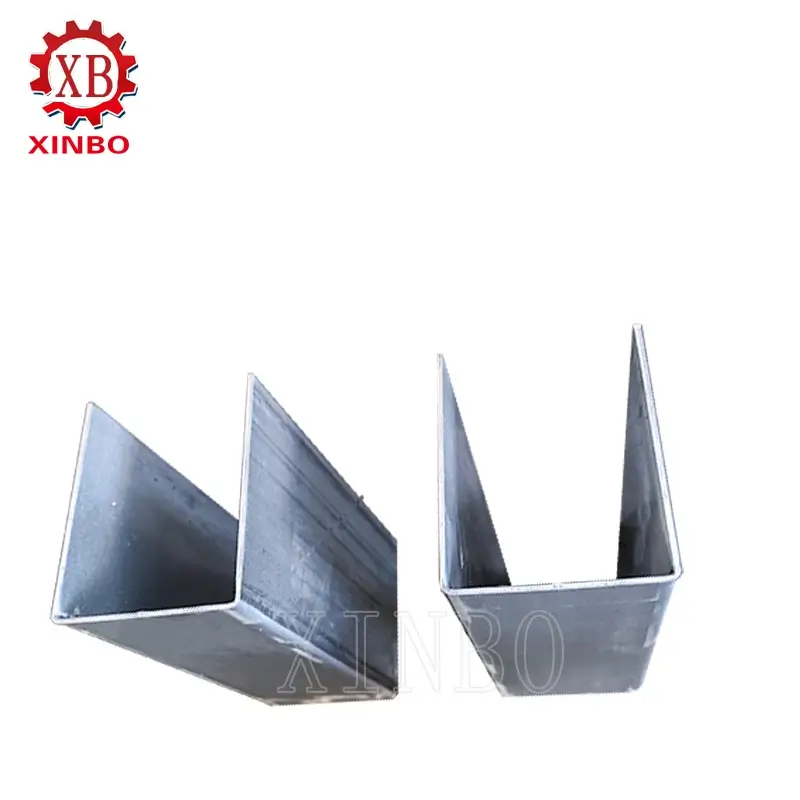

Wat is een U-kanaalrol die machine vormt?

Basically, a u channel roll forming machine is a special factory device built to change flat metal rolls or plates into ongoing U-shaped paths via a cool-shaping method.

These devices play a key role in fields that need building parts with even shapes, like frames, support bars, and edge setups. Unlike old pressing or pushing ways, roll forming applies steady bending to mold metal without warmth. This keeps the material strong and cuts down waste.

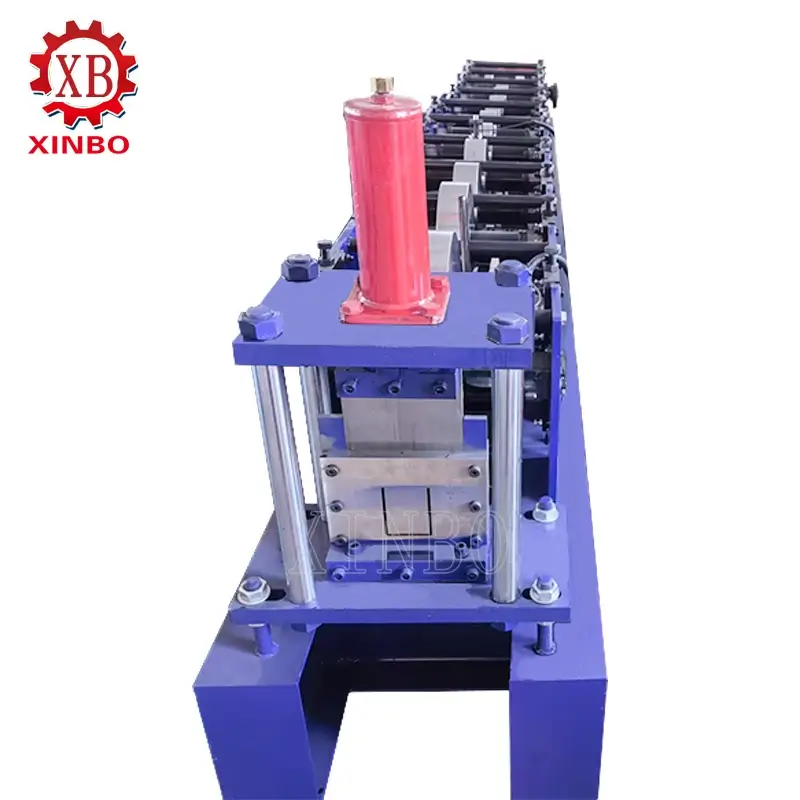

Main Components

The simple build of a u channel roll forming machine has many joined parts:

A decoiler for supplying raw stuff.

A set of shaping spots with exact rollers.

A cutting tool for length management.

An automatic piling system for result care.

Common materials handled include galvanized steel (GI), pre-painted galvanized steel (PPGI), aluminum mixes, and stainless steel. Thicknesses go from 0.5mm to 3mm. This flexibility makes the device essential for making paths in sizes from tiny furring pieces (e.g., 28mm x 27mm) to strong building shapes (up to 100mm wide).

For those wanting China u channel roll forming machine choices, the market shines in giving sturdy builds that mix low price with good output. These devices often have block designs. They allow simple addition of extras like hole-making units or pressing tools. Thus, they fit various job needs.

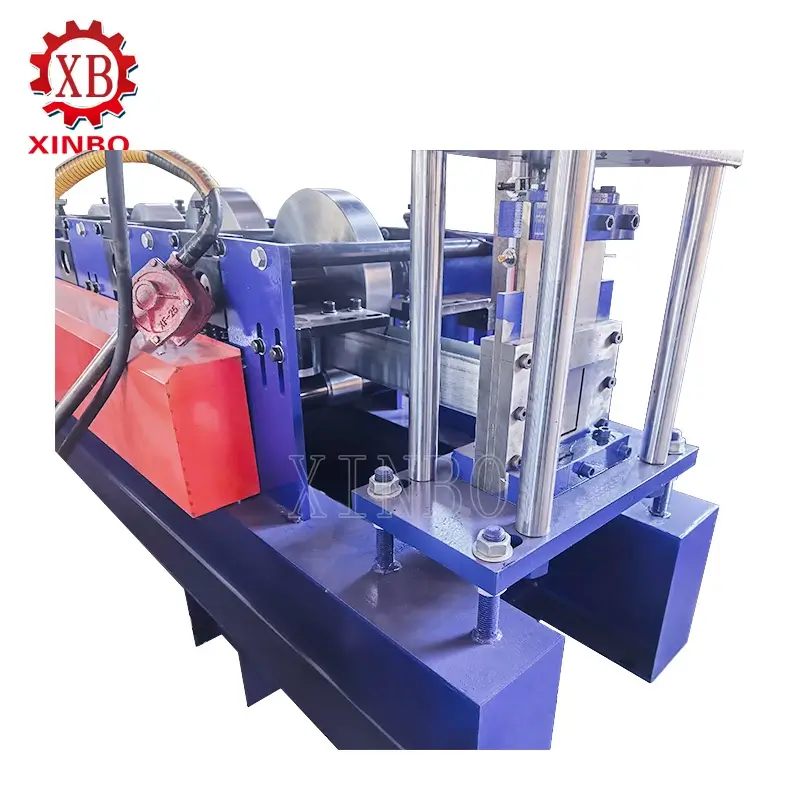

How Does a U Channel Roll Forming Machine Work?

The working of a u channel roll forming machine is a careful mix of exact building. Here, raw metal turns step by step into done shapes.

1. Material Feeding

A roll of metal, usually 5-10 tons heavy, loads onto a hydraulic decoiler. It unwinds the band at steady pull. Then, it sends it into the device at rates up to 30 meters per minute.

2. Leveling and Entry Guidance

The band moves through smoothing rollers to remove any roll-bend curve. This keeps flatness within 1mm per meter. Optional early-punching spots can make slots or holes for links. They use hydraulic or servo pulls exact to ±0.5mm.

3. Roll Forming Section

The main part of the machine holds 12-20 spots of matched rollers. These are from heat-fixed Cr12 steel (hardness HRC 58-62). Each spot adds a small bend. It starts with edge softening and moves to full side making. Slowly, it forms the band into a U shape.

The rollers get CNC-cut for evenness. This stops material strain that might cause bounce-back (usually kept under 0.5 degrees).

4. Cutting Phase

After shaping, the shape goes to the cutting step. A moving shear or after-cut hydraulic saw cuts the path to exact lengths (from 200mm to 12m). Tolerances stay ±1mm. After-work may add straightening via exit rollers or auto piling for grouping.

Technische specificaties

A usual custom u channel roll forming machine might have:

15-22kW main motor

PLC control with touch screen (Siemens or Delta systems)

Chain-drive transfer for trust

Making speed can hit 100m/min in better models. It gives up to 50 tons per shift with little stop time.

This ongoing, auto flow not only raises output but also keeps size steady. Thus, OEM u channel roll forming machine setups suit big amount runs.

Key Components of a High-Quality U Channel Roll Forming Machine

A high-level u channel roll forming machine gets defined by its matched parts. Each is built for lasting and exactness.

ontkoelaar

Often core-style with loads up to 10 tons and auto pull control to stop band shifting.

Feeding Guide

Lines the stuff using side sensors for no-mistake entry.

Forming Rollers

Usually 18-22 pairs, placed 400-600mm apart. They use general or set tooling. Fast-swap systems cut setup time from hours to minutes. This matters for wholesale u channel roll forming machine buyers.

Cutting Systems

Hydraulic shears give clean, no-burr edges for thinner measures. Moving cutoffs keep line rate for thicker shapes.

Controlesystemen

Run by PLC and servo motors. They join HMI screens for live checks of rate, length, and checks. Many also give Ethernet links for Industry 4.0.

Exit Table & Stacker

Air stackers auto handle. They cut work by 70%. Block parts allow growth upgrades, like adding line welding for closed shapes.

Advantages of Using U Channel Roll Forming Machines

Putting money in a u channel roll forming machine brings many gains:

Efficiency & Cost Savings

Uses 20-30% less power than hot-rolling choices and makes almost no waste. This leads to stuff savings of up to 5% per run. Fast work allows on-time making. It lowers stock costs.

Precisie

Limits as close as ±0.2mm ensure paths fit smoothly in groups. This cuts fix work by 50%.

Material Integrity

Cool shaping skips weak inner builds. It gives shapes with pull strengths over 350MPa.

Veelzijdigheid

Manages many mixes and thicknesses without change. It supports quick test making.

Environmental Compliance

Low releases fit green build rules like LEED.

For China u channel roll forming machine users, these gains grow with fair prices—often 30-40% under Western ones—without losing CE-passed quality.

Applications of U Channels in Modern Industries

Building Frameworks

U channels act as furring paths for drywall hanging. They give even bases over rough spots. Their carry power (up to 500kg/m) fits ceiling nets and wall tracks.

Infrastructure

Heavy kinds go in road guards, bridge growth links, and other build holds. They handle heat changes and hit forces.

Zonne-energie

Shape fixing rails for sun panels that bear high wind.

Automotive & Machinery

Light aluminum U channels serve for frame strength and carry guides. They value rust fight.

Storage Systems

Cut designs punched in line boost change for racks and shelves.

New uses include LED light spreads and sound walls. This shows the flex of U channels.

Choosing the Right U Channel Roll Forming Machine: OEM vs. Custom

Finding OEM u channel roll forming machine and custom u channel roll forming machine choices needs checking making wants.

OEM Models

Best for standard results, ready setups, and covers up to 24 months. They fit wholesale u channel roll forming machine cases. They give size savings.

Custom Builds

Great for special needs, like adding hole sets for set uses or changeable roller widths. Many u channel roll forming machine factories in China give full custom from CAD plans to site start. Wait times usually 45-60 days.

Selection Criteria

Fit machine power to output (10-50m/min)

Check stuff match

Focus on after-sale help like far checks

Plan for extras like auto-piling to safe future spends

Maintenance Tips for Longevity and Performance

Active care keeps a u channel roll forming machine running well:

Daily: Check rollers for use (swap if spaces over 0.1mm), oil chains.

Weekly: Clean decoiler cores and set sensors.

Quarterly: Test bearings with shake study.

Annually: Renew PLC code and do expert care.

For China u channel roll forming machine, getting OEM parts aids 95% run time. Teaching workers on fault signs cuts surprise stops by 40%.

Veelgestelde vragen

Q1: What materials can a u channel roll forming machine process?

A1: Galvanized steel, aluminum, and stainless steel in thicknesses from 0.5mm to 3mm; custom models up to 4mm.

Q2: How fast is production on a typical OEM u channel roll forming machine?

A2: Speeds range 10-30 meters per minute, enabling 20-50 tons daily output for wholesale operations.

Q3: Main differences between standard and custom machines?

A3: Standard models focus on fixed sizes; custom machines include adjustable rollers and integrated punching for specialized profiles.

Q4: How to select a reliable China u channel roll forming machine manufacturer?

A4: Look for CE/ISO certifications, 12-24 month warranties, and CNC tooling capabilities for quick prototyping and global support.

Q5: What maintenance is required?

A5: Routine lubrication, roller inspections, PLC calibrations every 500 hours; professional servicing annually.

Contact XINBO Today for Your Roll Forming Needs

Set to boost your making with a modern u channel roll forming machine?

Bij XINBO, we focus on giving OEM and custom answers fitted to your clear wants.

Visit our homepage for roll forming new ideas.

Check personal service asks on our services page.

Find our quality and skill on our about us section.

Neem contact met ons op via WhatsApp at +86 15373656508 or email for a free quote — your ideal China u channel roll forming machine awaits!

Gerelateerde berichten

Goede kwaliteit

XinBo-machine die CO. LTD maakt is een professionele fabrikant en exporteur in rolvormende machine,

Bekijk meer→

Spaans

Spaans Rusland

Rusland