How China Automatic Square/Round Downspout Roll Forming Machine Shapes Precision Drainage Systems

A downspout roll forming machine is a true wonder of modern building tech. It turns plain metal coils into smooth, strong tubes that guide water far from homes and offices.

Yet, when you need top accuracy and steady work, makers from China downspout roll forming machine stand tall. They give smart auto options that mix fresh tech with low prices. These units, especially the auto types for square/round downspout roll forming machine shapes, are changing water flow setups all over the world.

As a top leader in this area, XINBO has led the way since 2014. They supply super exact automatic downspout steel square round pipe machine answers that make perfect forming and joining.

Why Downspouts Are Essential for Effective Rainwater Drainage Systems

Downspouts form the main support of any roof and gutter plan. They grab rain from gutters. Then, they send it safely to ground pipes, storm lines, or far from building bases. This stops big problems like dirt wash, cellar floods, and wall breaks. In places with lots of rain or melting snow, one bad downspout can cause huge fix bills.

The Rise of Metal Downspout Roll Forming Technology

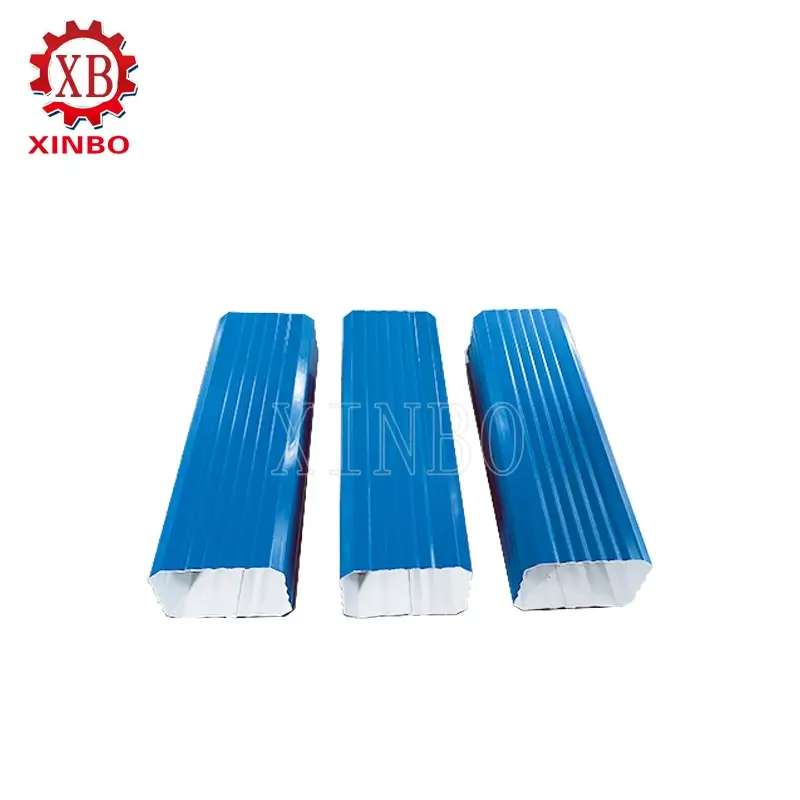

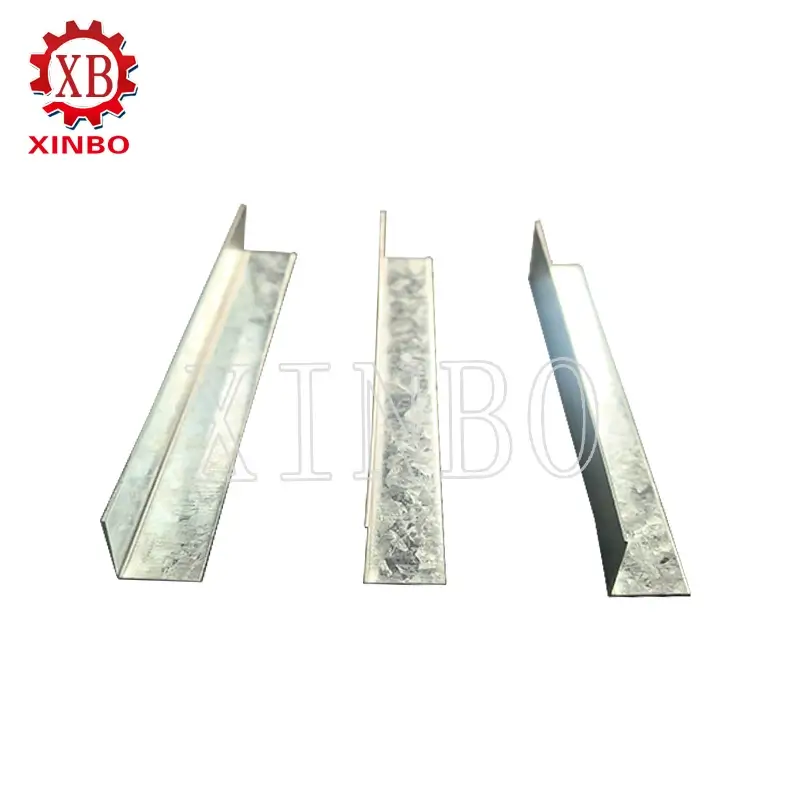

Old choices like PVC tubes or hand-bent metal often twist, break, or rust fast. Metal downspouts made by square/round downspout roll forming machine tech—mainly from China downspout roll forming machine sellers—give much better picks. Galvanized steel, aluminum, or pre-painted coils build tubes that fight sun rays, hot and cold shifts (-30°C to 80°C), and strong winds up to 150 km/h.

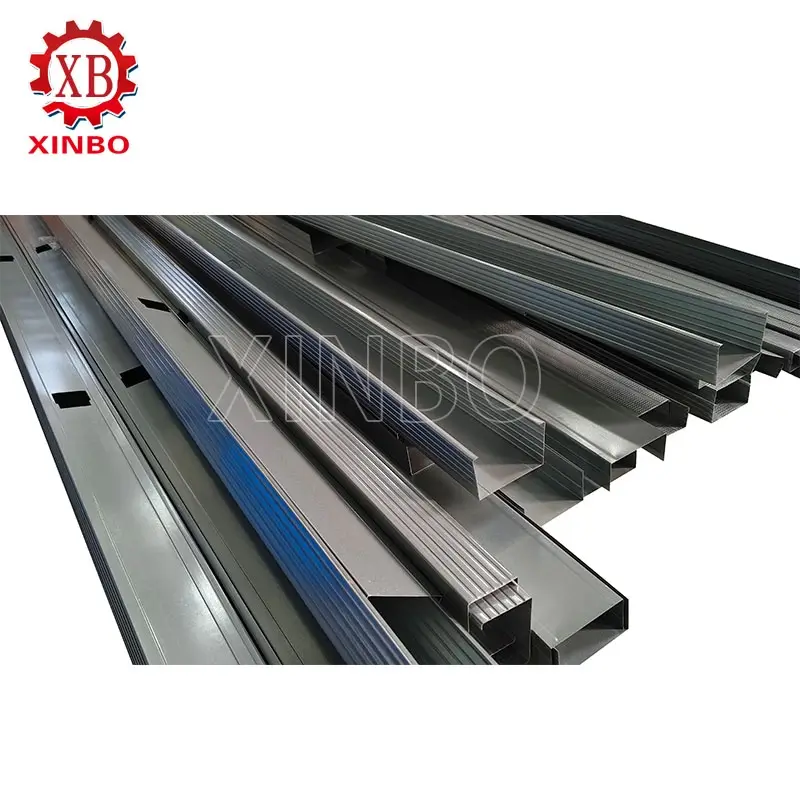

Square vs. Round Downspouts: Choosing the Right Profile

Square downspouts offer a neat, building-style view. They save wall room too. So, they fit well in business spots. Round downspouts shine in big water flow cases. They cut splash and swirl for easier drain. XINBO’s automatic downspout steel square round pipe machine makes sure both shapes hit exact sizes (e.g., 3×4 inch square or 4-inch round). They join easy with common gutter plans. From trade notes, well-set metal downspout setups can take rain falls of 150mm/hour. This matters more as wild weather grows around the globe.

How Roll Forming Achieves High-Precision Downspout Shapes for Optimal Performance

Exact work is not just nice—it’s the base for trusty water flow. A China automatic square/round downspout roll forming machine uses smart build to make even, no-leak tubes that beat old ways. Close fits as low as ±0.3mm give perfect joins. Auto steps wipe out uneven spots.

Engineering Excellence in Every Step

-

Progressive Shaping: 20-28 roller stops (built from Cr12MoV steel, hardened to HRC 60) slowly curve flat coils into end shapes. For square tubes, edge curves stay at 1.5-2mm to stop crack stress. Round tubes use inside rods for steady 0.5mm wall thick.

-

Seamless Joints and Flow Dynamics: Auto squeeze shrinks tube ends by 5-10mm for slide fits. This makes tight seals without glue. Computer flow studies in XINBO’s plan work fine-tune inside shapes. Round downspouts get 25% less water drag than wavy types.

-

Material and Finish Precision: Units take coil widths of 245-425mm. They add guard coats (PE, PVDF) before or after shape. Chrome-covered rollers stop marks on color steel. This keeps nice look for 20+ years.

Inside the Automatic Downspout Roll Forming Machine: How It Works

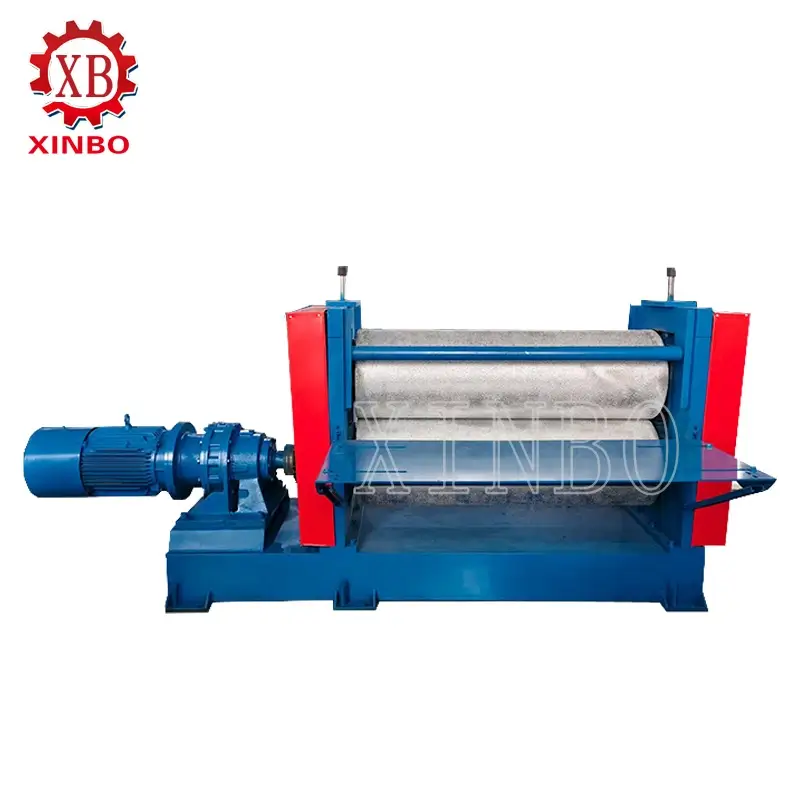

At the heart, a China automatic square/round downspout roll forming machine is a non-stop make line. It changes raw metal coils into ready tubes through exact machine and auto moves. Unlike hand curve ways, these units cut out people mistakes. They give steady good at speeds up to 15-20 meters per minute.

Key Components and Workflow

-

Decoiler en voedingssysteem: The start uses a power or hand decoiler. It opens coils of galvanized steel (0.4-0.8mm thick) or aluminum. Guide rollers keep feed smooth. They stop folds or shifts. XINBO’s types have servo drives for change tension. They fit widths from 200mm to 400mm.

-

Roll Forming Stations: This is the main part. A set of 18-26 tough steel rollers (Cr12MoV stuff, HRC 58-62 hard) slowly form the flat sheet. For square downspout roll forming machine, rollers make sharp 90-degree turns. For round ones, they build smooth arcs. Auto control via PLC (Programmable Logic Controller) from names like Siemens lets live tweaks for shape truth.

-

Hydraulic Cutting and Elbow Integration: After form, the tube cuts to length (up to 12m) with fly shear or power blade. This gives clean edges. Top automatic downspout steel square round pipe machine from China add built elbow makers. These curve tubes at 45° or 90° with air or servo movers. They make custom bends for hard sets. XINBO’s elbow parts include shrink tools to narrow ends for safe laps. This boosts join strength.

-

Output and Stacking: Ready tubes go to auto piles or out tables. They wait for pack. Safe bits like quick stops and guards cut stop time.

This flow is not only quick—it’s built for exact. Rollers get chrome to take painted coils without harm. Code feedback keeps length right within 1mm. For China downspout machine manufacturer like XINBO, custom fits matter. Units switch between square (e.g., 100x75mm) and round (e.g., 90mm diameter) shapes with fast tool change. Setup drops to under 30 minutes.

Benefits of Choosing a China Downspout Roll Forming Machine

Buying an automatic downspout steel square round pipe machine from China brings many wins. They cover money and green sides.

Economic and Operational Gains

-

Kostenefficiëntie: Make costs fall by 30-50% next to foreign ones. This comes from smooth auto work. One unit can push 5,000-10,000 meters each day. Waste stays under 2%.

-

Veelzijdigheid: Two-shape skill means one unit covers home (square, 3×4 inches) and work (round, 4-5 inches) jobs. XINBO’s block builds let add-ons for new shapes without full swap.

-

Scalability: Great for small firms. Move types fit in 20ft boxes for simple ship. Big models grow for plants.

Environmental and Sustainability Perks

Metal downspouts recycle fully. They match green build rules like LEED. Chinese units use stuff smart. They cut scrap by 25%. Power-save servo motors drop use by 20%. Low-gas form steps keep VOCs down.

Lange termijn betrouwbaarheid

With 10+ year promises and far checks, breaks are few. XINBO’s after help gives free code updates. Units stay with trade changes.

Spotlight on XINBO: A Trusted China Downspout Machine Manufacturer

Since 2014, XINBO has built a strong spot as a top China downspout machine manufacturer. They mix new ideas with sure work. Based in China, the firm focuses on custom roll form answers. They ship to Europe, the UK, and Canada. Their square/round downspout roll forming machine sets offer ODM/OEM choices. They follow UL, CE, and ROHS rules.

XINBO’s skill shows in exact build. Their auto lines use new PLC screens for touch control. Workers set batch from 1-10,000 pieces easy.

Check XINBO’s goods at www.cnxinbo.net. See how their automatic downspout steel square round pipe machine can boost your work.

Future Trends in Downspout Roll Forming Technology

Ahead, downspout roll forming machine new ideas speed up. AI add for guess fix could cut breaks by 40%. Mix stuff like aluminum-steel blends boost strong-light balance. In China, makers lead IoT units for live watch. This gives no-miss make.

Green push goes on. Look for bio coats and sun-power uncoil by 2027. For water flow, smart shapes that change to flow will be normal. This makes China downspout roll forming machine more key.

Veelgestelde vragen

What materials can a China automatic square/round downspout roll forming machine process? These units take galvanized steel (0.4-0.8mm), aluminum, stainless steel, and color-coated sheets with yield strengths up to 350 MPa. They make rust-proof, tough tubes.

How does precision in roll forming improve drainage system performance? Close fits (±0.5mm) build smooth shapes. They help even water move. They cut leaks. They hold high push. This adds system life by 20-30 years.

Can XINBO customize a downspout machine for specific profiles? Yes, XINBO gives ODM help. They fit units for custom square (e.g., 100x100mm) or round (e.g., 90mm) sizes. Fast tool change adds flex.

What is the production speed of an automatic downspout steel square round pipe machine? Speeds hit 15-20m/min. They give up to 10,000m daily. PLC auto keeps batch same. Waste stays low.

Upgrade Your Drainage Solutions with XINBO Today

Want to lift your rain control with exact-built downspout roll forming machine tech? XINBO’s China automatic square/round downspout roll forming machine brings top speed, strength, and custom fits. Don’t let weak flow slow your jobs—pick plans that work great.

Contact XINBO Now for a Free Consultation and Quote! Visit www.cnxinbo.net to see our full line. Jump into our skill at About Us. Find smooth help at Services.

Email: serena@cnxinbo.net| Call: +8615373656508 Change your make—build the next of water flow with XINBO!

Gerelateerde berichten

-

Applications of Light Steel Metal Keel Roll Forming Machines Across the Building Industry

-

Automatic Metal Embossing Machine Guide: Top China Embossing Machines for Metal Plates

-

Efficient and Versatile: Light Steel Keel Forming Machine

-

Customized Full Automatic L Wall Angle Roll Forming Machine from China Manufacturer — Good Price & High Quality

Goede kwaliteit

XinBo-machine die CO. LTD maakt is een professionele fabrikant en exporteur in rolvormende machine,

Bekijk meer→

Spaans

Spaans Rusland

Rusland