Advantages of Using High-Speed Automatic Steel Coil Slitting Lines | Steel Coil Slitting Line Manufacturer

In the busy world of making metal stuff, getting things right and fast is super important. That’s where high-speed automatic steel coil slitting lines come in. These cool machines turn big steel coils into thinner strips super quickly and exactly. As a top steel coil slitting line manufacturer, XinBo în wants to explain how this awesome tech works. Let’s dive in!

What Are High-Speed Automatic Steel Coil Slitting Lines?

At their core, high-speed automatic steel coil slitting lines are neat machines that cut big steel coils into smaller strips. They handle everything from unrolling the coil to rolling up the finished strips. It’s all done in a smooth, automatic way, like a conveyor belt at a grocery store but for steel.

The Basic Anatomy of a Steel Coil Slitting Line

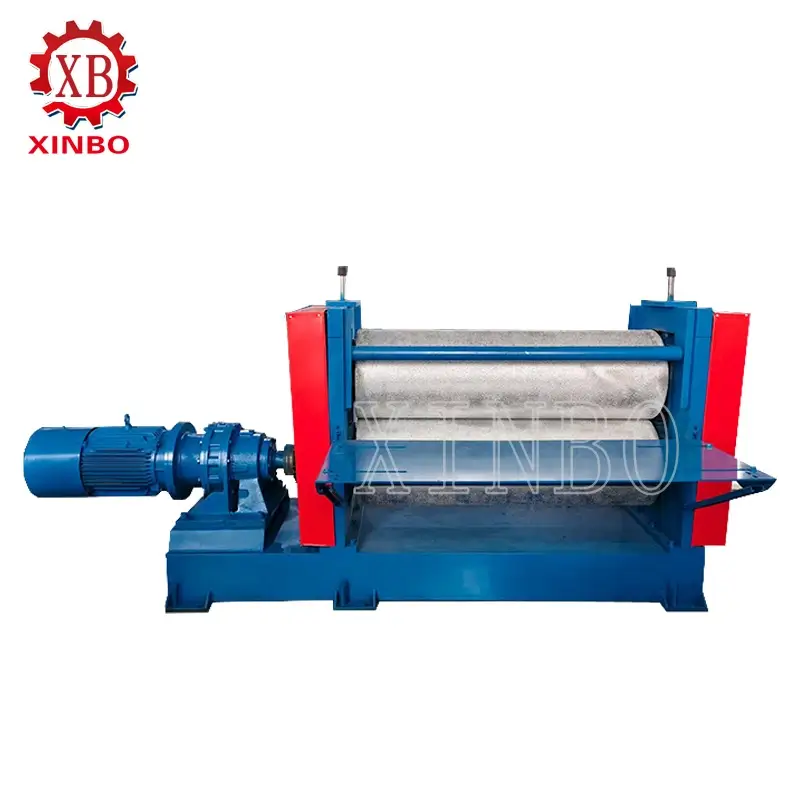

A steel coil slitting line has a bunch of parts that work together:

-

decoilator: This is where it starts. A heavy steel coil, sometimes weighing tons, gets loaded and unrolled. Fancy models have hydraulic arms to hold the coil tight, so it doesn’t slip during fast work.

-

Entry Guide and Pinch Rolls: These line up the coil and push it into the cutting part. They keep the steel steady to avoid any mess-ups.

-

Slitting Head: The main star! It has spinning knives or sharp blades that cut the coil into strips. For high-speed lines, these knives are super tough and controlled by computers to be crazy exact.

-

Recoiler: After cutting, the strips get rolled back into coils. Special systems keep them tight and neat, which is key for the next steps, like making metal sheets.

-

Ancillary Systems: Scrap choppers clean up extra bits from the edges. Edge separators keep strips apart. Modern lines use PLC systems with touchscreens, so workers can set things up easily.

These lines can handle steel coils up to 30 inches thick and wider than 60 inches. They can go as fast as 300 meters per minute in high-speed setups. At XinBo, we make modular designs that grow with your needs, whether you’re working with hot-rolled, cold-rolled, or galvanized steel.

Evolution from Manual to Automatic

Old-school slitting lines needed workers to adjust things by hand. That caused mistakes and slowed things down. Now, high-speed automatic steel coil slitting lines use motors, sensors, and smart tech to fix issues on their own. Thanks to Industry 4.0, they’re up to 70% faster. That makes them a must for big jobs.

How Do High-Speed Automatic Steel Coil Slitting Lines Work?

Knowing how these machines run helps you see why they’re so cool. A high-speed automatic steel coil slitting line works like a well-oiled team, mixing strong parts with brainy tech.

Proces pas cu pas

-

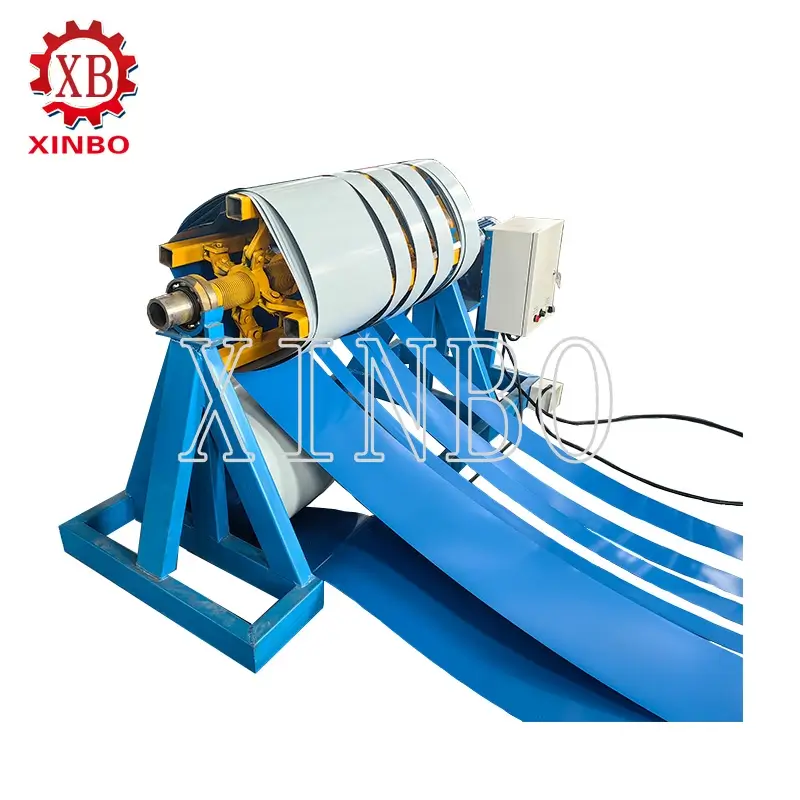

Coil Loading and Uncoiling: The coil goes on the decoiler. Hydraulic arms grab it tight by the inner diameter (ID). When the machine starts, the coil unrolls at a steady speed. Loop accumulators catch any wobbles to keep things smooth.

-

Alignment and Tensioning: Pinch rolls grab the steel strip. They feed it through rollers that fix any bumps from the mill. Tension bridles add even pressure, so the steel doesn’t wrinkle. This is super important for fast runs where shaking could mess things up.

-

Slitting Phase: The big moment! The coil goes between spinning knives set for the strip widths you want, as small as 0.5 inches. In automatic mode, lasers help adjust the knives if the steel thickness changes.

-

Edge Trimming and Waste Management: Extra bits on the edges get chopped off by fast cutters. Pneumatic systems whisk the scraps away, keeping the workspace tidy and saving material.

-

Recoiling and Unloading: The cut strips go to separate recoiler mandrels. Hydraulic expanders hold the cores tight. Automatic wrappers add protective covers for shipping.

Sensors watch things like thickness, width, and speed. If something’s off—like the coil drifting—the machine stops or fixes itself, so there are no mistakes.

Technical Specs That Define High-Speed Performance

Top-notch steel coil slitting lines have:

-

Viteza: 150–300 m/min, so they can work all day and night.

-

Toleranță: ±0.005 inches for width and ±0.001 inches for thickness, super exact.

-

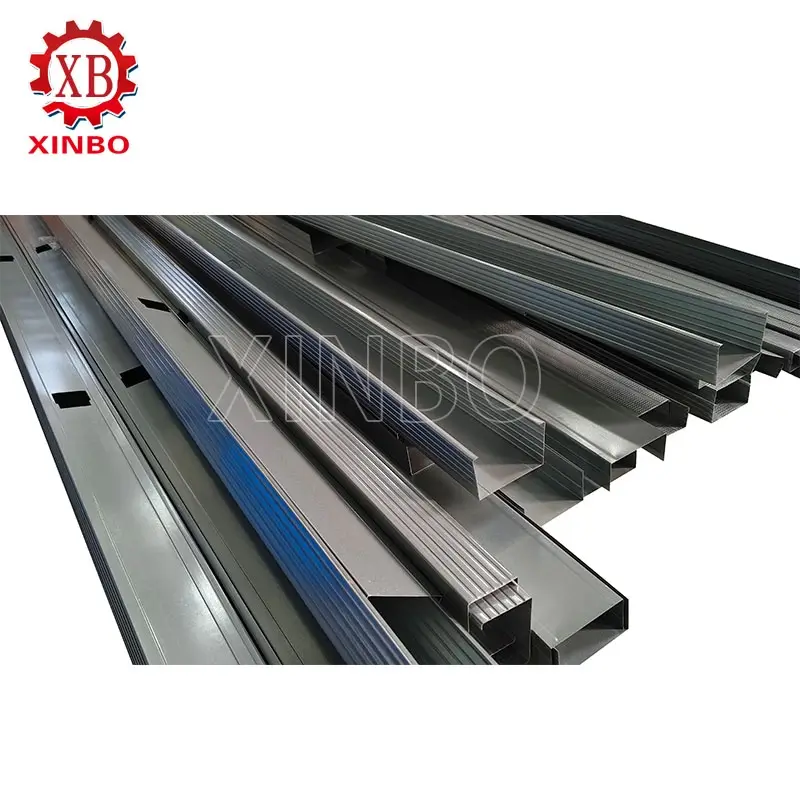

Material Range: Coils from 0.2mm to 20mm thick, handling steels up to 1500 MPa strength.

-

Nivelul de automatizare: Full IoT setup for checking issues from far away and planning maintenance.

This isn’t just fancy stuff—it turns raw coils into perfect materials for other jobs.

Key Advantages of High-Speed Automatic Steel Coil Slitting Lines

Let’s talk about why high-speed automatic steel coil slitting lines are so great. These perks come from years of smart engineering and real-world use.

Super Fast and Productive

Old ways took hours to slit a 20-ton coil. These machines do it in minutes. Automatic controls mean no stopping for adjustments, boosting output by 50–100%. This helps factories meet tight deadlines without extra costs.Really Exact and High Quality

Hand slitting can leave rough edges or uneven strips, ruining batches. High-speed lines use sharp knives and smart sensors to make clean cuts. Quality checks catch problems right away, cutting rework by up to 80%. This is key for industries like aerospace, where every cut needs to be perfect.Economizează bani

These machines cost a bit upfront, but they pay off fast. Energy-saving motors use 30% less power. Less waste (edge trims under 1%) saves materials. Smart maintenance stops breakdowns, making machines last 20+ years. Overall, costs drop 20–40%, based on industry stats.Safer and Easier for Workers

Automation keeps workers away from heavy coils and sharp blades. Features like emergency stops and safety covers follow OSHA and ISO rules. Workers just watch, making the job safer and more fun.Works for Lots of Jobs

These lines handle all kinds of steel, from soft to super strong. Quick-change tools let you switch tasks fast. They’re great for small test runs or huge factory jobs, perfect for custom orders.Good for the Planet

By cutting exactly and wasting less, these lines use fewer raw materials. That’s great for green goals. Some models even save energy, cutting carbon use by 25%.

In short, these machines make work faster, smarter, and cheaper.

Aplicații în întreaga industrie

High-speed automatic steel coil slitting lines are key for tons of industries.

Automotive and Transportation

Slit strips make car parts like chassis, doors, and tubes. Exact cuts ensure safe, strong vehicles, especially for electric cars with tough steel.

Construction and Building Materials

Narrow strips go into roofing, siding, and frames. Fast lines help deliver materials right on time for big building projects.

Appliances and Consumer Goods

From washer drums to shelves, even strips make assembly easy. Galvanized steel fights rust in wet places.

Energy and Renewables

Slitting for solar panel frames or wind turbine blades needs perfect cuts. These lines make it happen without a hitch.

Packaging and HVAC

Thin strips create ducts, cans, and boxes. Fast speeds match busy seasons.

For example, a big European car supplier used a steel coil slitting line. It cut lead times from weeks to days and boosted output by 40%.

Maintenance and Best Practices for Longevity

To keep these awesome benefits, you need to take care of the machine.

Routine Maintenance Tips

-

Daily: Check knives for wear and clean rollers.

-

Weekly: Oil bearings and check sensors.

-

Annually: Get pros to check alignment and update software.

Common Pitfalls to Avoid

Don’t overload coils or skip tension checks. That can cause jams. Train workers well—it saves time and money.

Future-Proofing with Tech

Use AI to spot problems early. This keeps your high-speed automatic steel coil slitting line ready for the future.

Întrebări frecvente

What materials can high-speed automatic steel coil slitting lines process?

They handle carbon steel, stainless steel, aluminum, galvanized, and pre-painted coils, with thicknesses from 0.2mm to 20mm.How fast are these lines really?

Top models go 150–300 meters per minute, depending on the material and width.What’s the difference between high-speed and standard slitting lines?

High-speed ones have better automation, faster motors, and real-time controls for more output and accuracy.Are these lines customizable?

Yes! At XinBo, we offer ODM/OEM options to tweak things like coil width, speed, and tech add-ons.How do I know if my facility needs one?

If you handle lots of coils and want faster work, it’s a great fit. Ask a manufacturer for a check-up.

Partner with XinBo: Your Trusted Steel Coil Slitting Line Manufacturer

Ready to power up with high-speed automatic steel coil slitting lines? Since 2014, XinBo în has been a top maker of cool metal shaping machines, with over 10 years of know-how. Our machines meet global IEC standards and have UL, TUV, CE, CQC, ROHS, and REACH certifications for awesome quality.

We focus on ODM and OEM services, making custom steel coil slitting lines with quick delivery and great support. For Europe, the UK, Canada, or anywhere else, our designers and engineers build trusty, high-performance machines to help you win.

Contact XinBo today via WhatsApp at +86 150 0321 6790 or visit www.cnXinBo.net to talk about your project. Let’s cut the path to better work together!

Posturi legate

-

Automatic Metal Embossing Machine Guide: Top China Embossing Machines for Metal Plates

-

Simple Metal Coil Slitting Line Wholesale: High Precision Rolling Stainless Steel Coil Strip Slitting Machines

-

Efficient and Versatile: Light Steel Keel Forming Machine

-

What is a Container House Top Beam Roll Forming Machine? A Guide for New Buyers

-

How to Choose the Best EPS Sandwich Roof Panel Production Line Machine for Your Business

Bună calitate

XinBo mașină de fabricare CO. LTD este un producător profesionist și exportator în rula de formare mașină,

Vezi mai multe→

spaniolă

spaniolă Rusia

Rusia