Applications of Light Steel Metal Keel Roll Forming Machines Across the Building Industry

Meet the light steel metal keel roll forming machine. It is a big shifter that is softly changing how we put up all kinds of places, from warm houses to tall business spots. If you have ever thought about how smooth, strong buildings go up so fast with little trash, this tool sits right in the middle of it. People also call it the light steel keel roll forming machine or light gauge steel keel roll forming machine. This smart gear turns flat steel rolls into exact, light shapes. These shapes make the main support for many building jobs.

The Basics: How Light Steel Metal Keel Roll Forming Machines Work

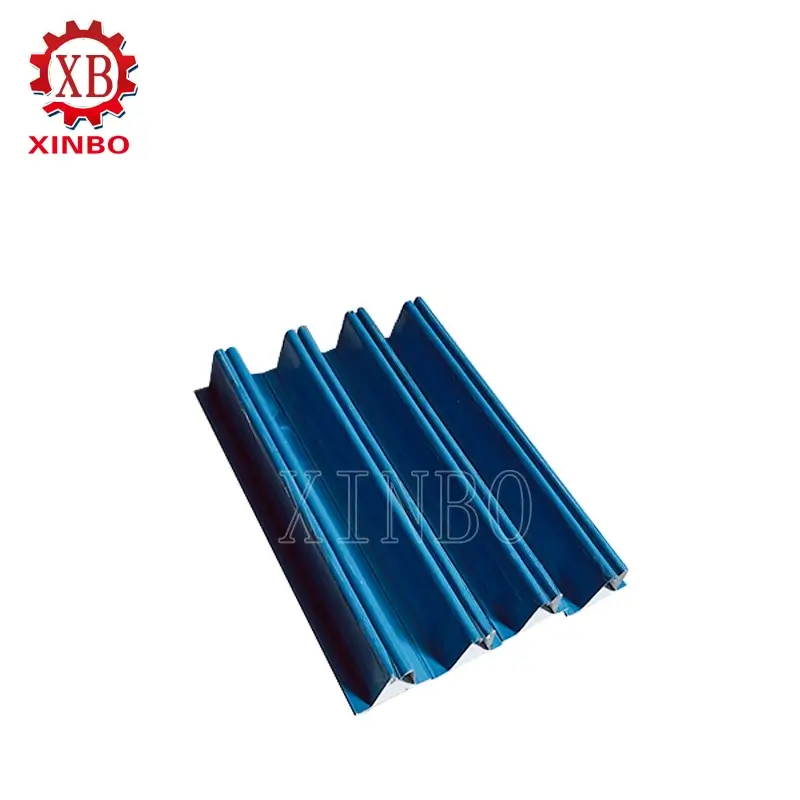

Before we jump to the fun uses, here is a short look at the tech. A light steel keel roll forming machine runs in a steady flow. Galvanized steel coils go into the gear. Then, many well-made rollers slowly bend and form the metal into special shapes. Think C-studs, U-tracks, or omega channels. Hydraulic parts take care of cutting and hole-making. Smart PLC controls keep errors as small as ±0.5mm. This is not just a tool. It is a smooth dance of auto work. It makes light but tough parts at speeds that reach 100 meters per minute.

What makes the precision light steel keel roll forming machine stand out is its skill with thin steel (0.7-2.0mm). It keeps the power strong. These units are small. They fit in a normal 40-foot container. That helps with shipping around the world. They are built strong too. Solid shafts go up to 90mm across. Frames use Q235 steel. In China, where new making ideas meet world needs, the light steel keel roll forming machine is changing building ways. It lets teams make frame parts fast, right at the site or in plants. Before, these parts took a lot of hand work.

Core Applications: From Foundations to Finishes

The real strength of light steel metal keel roll forming machines shows in their many uses. These shapes are not for one job only. They are the hard workers in building. They help with main frames and pretty ends. Here is a simple list of main ways to use them:

1. Lightweight Steel Framing Systems for Residential and Commercial Buildings

Lightweight steel framing leads the list. Light gauge steel keel roll forming machines make studs, tracks, and joists. These take the place of old wood or heavy steel. In home building, the shapes build the bones for low homes and nice villas. They allow spans up to 6 meters with little bend. Picture putting up a two-floor house in days, not weeks. The machine gives pre-made panels. They fit together like toy blocks. Holes come pre-made for wires and pipes.

For business spots, they fit well in offices and shops. The shapes have a high power-to-weight level (up to 550 MPa yield strength). They hold multi-floor frames. At the same time, they cut base loads by 30-50% next to concrete. In shake areas, their bendy nature takes in quake force. That makes them safer. A precision light steel keel roll forming machine makes every stud the same. This cuts site mistakes. It speeds up putting together by up to 40%.

2. Interior Partition Walls and Suspended Ceilings

No new inside space skips bendy walls. Light steel keel roll forming machines shine here. They shape non-weight walls with C and U profiles. These match easy with gypsum board or sound panels. You can change the walls fast. This works great for office changes or hospital parts. No big mess or loud breaks.

Dropped ceilings are a strong point too. The machine makes main tees, cross tees, and wall angles. These build grid setups for lower ceilings. They hide air ducts and lights. They also help with sound. In busy spots like schools or hotels, the shapes fight wet air and hits. Hot-dip galvanization stops rust for 50+ years. The good points of a light steel keel roll forming machine show clear. Making costs fall by 20-30% from auto work. Put-up time cuts in half. Workers build grids in hours, not days.

3. Drywall Systems and Cladding Solutions

Drywall setup needs light steel metal keel roll forming machines a lot. They make furring channels and tough bars. These stop sound from room to room. In group homes, they cut noise by up to 50dB. That gives quiet living. The machine can change for widths (50-150mm). It fits curved or slanted walls just right.

For outside covers, the shapes make rain screens and air-flow fronts. They help save energy. Air moves behind panels. In green jobs, they join with warm panels. This cuts heat loss and raises R-values. A light gauge steel keel roll forming machine changes this. It lets teams make parts when needed. No big piles of stuff.

4. Roofing, Prefabricated Structures, and Modular Housing

Roof jobs use hat channels and Z-purlins from these machines. They work for steep or flat roofs in storage spots and gyms. Light weight makes moving and putting up easy. It cuts crane time and worker costs.

Pre-made and modular building is where the big change happens. Plants use light steel keel roll forming machines. They turn out wall panels, floor supports, and roof supports for off-site work. This way cuts build trash by 90%. It shortens time by 50%. It fits world goals for zero-carbon places. In quick help homes, fast modules from these shapes give strong shelters in under 24 hours.

5. Industrial and Agricultural Extensions

Uses go past city builds. They reach factories, car sheds, and farm buildings. The machine makes strong trusses for big roof spans in plants. They hold heavy tools without drop. In farms, greenhouse frames use rust-proof shapes. They stand bad weather. Structures last many years more.

Benefits of Using a Light Steel Keel Roll Forming Machine: Why It’s a Smart Investment

The uses grab attention. But the good points close the choice. First, speed stands out. These machines push output to 35-40m/min. They cut worker needs by 60%. They allow make-when-needed work. Cost cuts come next. Trash falls under 1%. Light shapes mean less ship fees. Profiles weigh 20-30% less than wood ones.

Green points shine bright. Steel recycles fully, 100%. The way uses 70% less power than hot-roll ways. Shapes give top fire hold (up to 2-hour ratings). They stop bugs. This cuts fix work over time. Exact controls give perfect fits. Fewer call-backs.

In China, the light steel keel roll forming machine spreads these wins worldwide. Makers like XINBO în lead with new, box-fit designs.

Choosing the Right China Light Steel Keel Roll Forming Machine: A Buyer’s Guide

Picking the best machine? Start with power. Match coil thick (0.7-2.0mm) and speed to your amount. Choose build-you-way designs with servo punch for change. Check controls. PLC with touch screens win over hand ones. Good light steel keel machine makers focus on CE-mark parts and 18-24 month promises.

Think about links. In-line stack and mark add-ons smooth work flow. Money? Basic models cost low. But exact adds pay in good parts. Last, team with pros who give custom fits. Key for odd shapes.

The Future: Light Steel Metal Keel Roll Forming Machines Driving Industry Innovation

As building moves to modular and green ways, these machines will grow. AI-smart rollers and IoT watch for fix-ahead come next. Their part in no-carbon jobs will grow. They stay as must-have tools.

In short, the uses of light steel metal keel roll forming machines cover frames, insides, outsides, and more. They bring fast work, strong build, and green ways. They help plants run better or make dream homes. They are key tools.

Întrebări frecvente

Q: What materials are used in light steel keel roll forming machines?

A: Primarily hot-dip galvanized steel coils (0.7-2.0mm thick) for corrosion resistance, with options for aluminum or copper.

Q: How fast can a light gauge steel keel roll forming machine produce profiles?

A: Up to 100m/min, depending on the model, enabling high-volume output for large projects.

Q: Are these machines suitable for custom profiles?

A: Yes, precision models allow adjustments for C, U, Z, or omega shapes via programmable controls.

Q: What maintenance do light steel keel roll forming machines require?

A: Regular lubrication of rollers and annual inspections; most offer 18-24 month warranties.

Q: Can they handle seismic zones?

A: Absolutely—their ductile profiles absorb shocks, meeting international building codes.

Ready to Elevate Your Construction Game? Partner with XINBO Today!

XINBO is a Chinese manufacturer of roll-forming and metal-shape machines. It started in 2014. They focus on cold-rolling machines, roll forming machines, light steel keel machines, wall/roof panel machines, metal IBR machines, and more.

Do not let old ways slow your jobs. Find out how XINBO’s top light steel keel roll forming machines can change your steps. They bring matchless exact work and speed.

Reach us now for a free quote. Change your builds. Your next job needs XINBO quality. Let’s make the future as a team!

Posturi legate

Bună calitate

XinBo mașină de fabricare CO. LTD este un producător profesionist și exportator în rula de formare mașină,

Vezi mai multe→

spaniolă

spaniolă Rusia

Rusia