What to Look for When Selecting the Best Decorative Wall Panel Roll Forming Machine

How a Modern Decorative Wall Panel Roll Forming Machine Actually Works

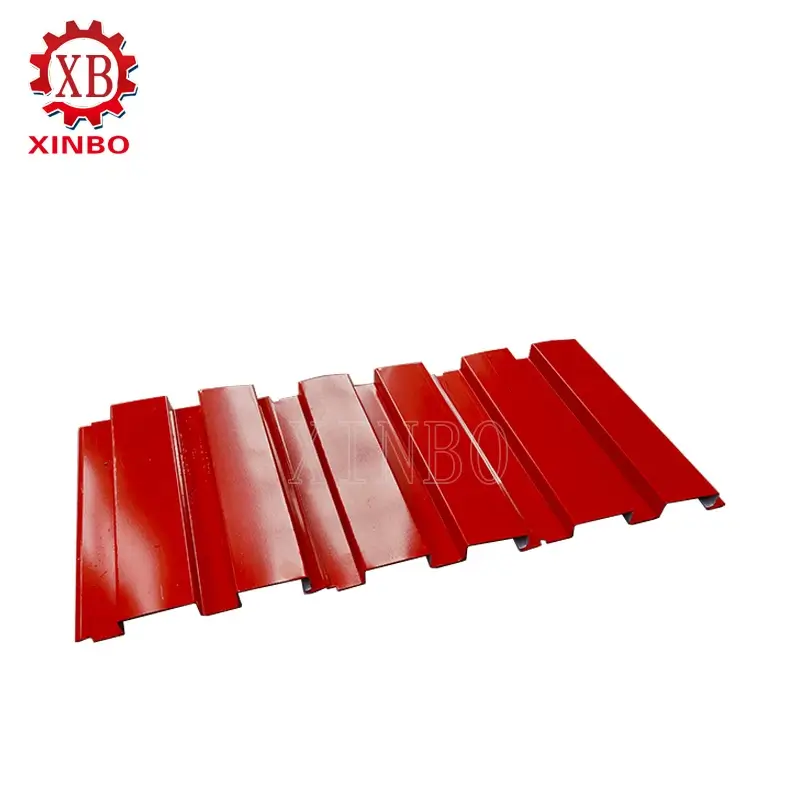

А decorative wall panel roll forming machine is a continuous cold-forming production line that converts flat metal coil into finished architectural panels with complex aesthetic profiles. The core principle is progressive bending: the strip passes through 18–30 pairs of contour rollers, each performing only 5°–15° of deformation. This gradual process prevents coating cracks, spring-back, and internal stress that would destroy the decorative finish.

Modern decorative panels CNC roll forming machines integrate servo-driven length measurement, flying cut-off, and recipe-based PLC control, achieving dimensional tolerances of ±0.3 mm and surface quality suitable for Class A architectural façades.

Essential Components of a High-Precision Decorative Wall Panel Roll Forming Machine

1. Decoiler & Coil Handling System in Decorative Wall Panel Roll Forming Machines

Capacity: 5–15 tons (8–10 tons most common) Type: Hydraulic mandrel expansion + brake or active servo decoiling Features required for decorative work:

- Double-arm decoiler for non-stop coil change

- Ultrasonic loop control to maintain constant 0.2–0.3 % tension on pre-painted coils

- Coil car with hydraulic lifting and centering

2. Precision Straightening Unit in Decorative Wall Panel Roll Forming Machines

9–13 rollers (typically 11) with 4-high or 6-high configuration Individual servo adjustment of upper rollers (±0.01 mm) Edge-wave and center-buckle removal capability up to 1.5 mm in 0.5 mm material Anti-scratch PU or nylon coated pinch rolls for glossy finishes

3. Roll Forming Stands – The Core of Every Decorative Wall Panel Roll Forming Machine

Shaft diameter: Ø70–Ø90 mm (Ø80 mm is the sweet spot for decorative precision) Roller material: Cr12MoV / SKD11 / D2, vacuum quenched HRC 59–61, finish ground and PVD or hard-chrome coated Housing: 30–40 mm welded & annealed steel plate, CNC-machined parallelism ≤0.02 mm Stand design options:

- Fixed individual stands (cheapest)

- Cassette/rafted system (10–15 min changeover)

- Duplex (double-layer) machines for two completely different decorative profiles simultaneously

4. Transmission Systems Used in Professional Decorative Wall Panel Roll Forming Machines

- Traditional: one motor + universal joint shaft (reliable, lower cost)

- Individual AC servo per stand (highest accuracy, fastest acceleration)

- Hybrid: main motor + individual servo on first 6 and last 6 stands (best compromise)

5. Cutting Technology That Defines Decorative Wall Panel Roll Forming Machine Quality

Hydraulic stop-cut shear → unacceptable for decorative pre-painted material (causes edge deformation) Servo flying saw with twin-blade system → current industry standard (±0.5 mm at 25 m/min, zero surface damage) Flying die-cut for perforated decorative patterns or complex end notches

6. Advanced Control & Automation in Today’s Decorative Panels CNC Roll Forming Machines

PLC: Siemens S7-1200/1500, Mitsubishi Q-series, or Beckhoff HMI: 12–15 inch color touchscreen with recipe storage for 200+ profiles Functions you should demand:

- Real-time length correction via encoder feedback

- Automatic speed compensation for material thickness variation

- Remote access via VPN for troubleshooting

- Industry 4.0 ready (OPC-UA, MQTT)

Production Workflow of a State-of-the-Art Decorative Wall Panel Roll Forming Machine

- Coil loading → hydraulic expansion & centering

- Automatic strip welding (optional for 24 h non-stop)

- Precision straightening → pre-notching / embossing station

- Progressive forming (20–28 passes for deep decorative profiles)

- In-line surface inspection camera (detects coating scratches >0.1 mm)

- Servo flying cut triggered by high-precision encoder

- Gentle transfer via vacuum or soft PU conveyor

- Automatic stacking & bundling (up to 60 panels/min)

Critical Technical Selection Criteria for the Best Decorative Wall Panel Roll Forming Machine

|

Параметр |

Minimum Acceptable |

Recommended for Premium Decorative Work |

|

Thickness range |

0.3–0.8 mm |

0.25–1.2 mm |

|

Forming speed |

12–18 m/min |

18–28 m/min (servo line) |

|

Length tolerance |

±1.0 mm |

±0.3–0.5 mm |

|

Profile changeover time |

<2 hours |

10–20 minutes (cassette) |

|

Roller life before regrinding |

800,000 m |

1.5–3 million m |

|

Frame plate thickness |

25 mm |

35–40 mm stress-relieved |

|

Shaft diameter |

Ø65 mm |

Ø80–90 mm |

Material Compatibility Guide for Decorative Wall Panel Roll Forming Machines

Best results achieved with:

- Pre-painted GI/PPGI (PVDF, SMP, HDP coatings)

- Aluminium 3003/5052 H46, pre-painted or mill finish

- Alu-zinc (Galvalume) AZ100–AZ150 with polyester coating

- Stainless steel 304/316 2B or hairline (requires special roller coating)

Avoid high-strength steel >550 MPa unless the machine has reinforced stands and slow-speed mode.

Common Mistakes That Destroy Decorative Panel Quality

- Using hydraulic stop-cut on 0.4 mm pre-painted material → visible dents

- Running >30 m/min on deep embossed profiles → coating micro-cracks

- No straightener adjustment when changing coil batch → wavy edges

- Poor loop control → tension marks on glossy surfaces

Maintenance Schedule for Maximum Uptime of Your Decorative Wall Panel Roll Forming Machine

Daily: clean metal dust, check oil levels Weekly: lubricate all grease points, inspect roller gaps Monthly: laser alignment check of all stands (±0.02 mm) Quarterly: hydraulic oil analysis + filter replacement Annually: full geometry measurement with laser tracker + roller regrinding if needed

Safety Standards Every Serious Decorative Wall Panel Roll Forming Machine Must Meet

- CE marking or NR-12 (Brazil) / OSHA compliance

- Full perimeter fencing with monitored safety doors

- Two-hand control for coil loading

- Light curtains + laser scanners at entry/exit

- Emergency wire along entire line length

FAQ – Everything You Need to Know About Decorative Wall Panel Roll Forming Machines

Q1: What is the real difference between a roofing roll forming machine and a decorative wall panel roll forming machine?

A: Decorative machines require 2–3 times tighter tolerances, surface-protection systems, servo flying cut-off, and often embossing stations. Roofing machines prioritize speed and water-tightness; decorative machines prioritize aesthetics and coating integrity.

Q2: Can one decorative wall panel roll forming machine produce both flat smooth panels and deep grain textures?

A: Yes — with quick-change cassettes or duplex configuration, changeover takes 10–20 minutes.

Q3: What speed should I expect without damaging pre-painted coatings?

A: 15–25 m/min is the safe zone for most decorative profiles. Above 28 m/min requires special low-friction rollers and coating tests.

Q4: Is servo flying cut-off really necessary?

A: For any pre-painted or textured decorative panel, yes. Hydraulic stop-cut systems deform the profile and scratch the coating.

Q5: How long do rollers last on a high-quality decorative panels CNC roll forming machine?

A: 1.5–3 million linear meters before first regrinding when using PVD-coated Cr12MoV/D2 and proper lubrication.

Q6: Can these machines produce perforated decorative panels?

A: Yes — with high-speed servo punch press before forming or flying die-cut station after forming.

Q7: What is the typical power consumption?

A: 18–35 kW depending on line speed and number of servo axes (much lower than old hydraulic lines).

Ready to Specify Your Next Decorative Wall Panel Roll Forming Machine with Confidence?

ХИНБО is a specialist manufacturer of decorative wall panel roll forming machines, wall decorative panel roll forming machines, decoration panel roll forming machines, and decorative panels CNC roll forming machines. Since its founding in 2014, XINBO has focused on customized machine design, tooling, process optimization, and rigorous testing — delivering reliable, flexible systems capable of producing high-precision decorative metal panels. Their machines are used in architectural façades, interior cladding, and decorative structure manufacturing.

For a tailored quote, technical drawings, or a sample panel production using your own material and profile, contact XINBO on their website. Request a factory sample run with your coil specification, so you can verify surface finish, profile accuracy, and cycle speed before committing to a purchase.

Связанные посты

Хорошее качество

XinBo машина, делающая CO. LTD является профессиональным производителем и экспортером в машине для формирования рулона,

ПРОСМЕТЬ БОЛЬШЕ→

Испанский

Испанский Россия

Россия