Automatic Floor Decking Tile Roll Forming Machines: Benefits & Applications

Введение

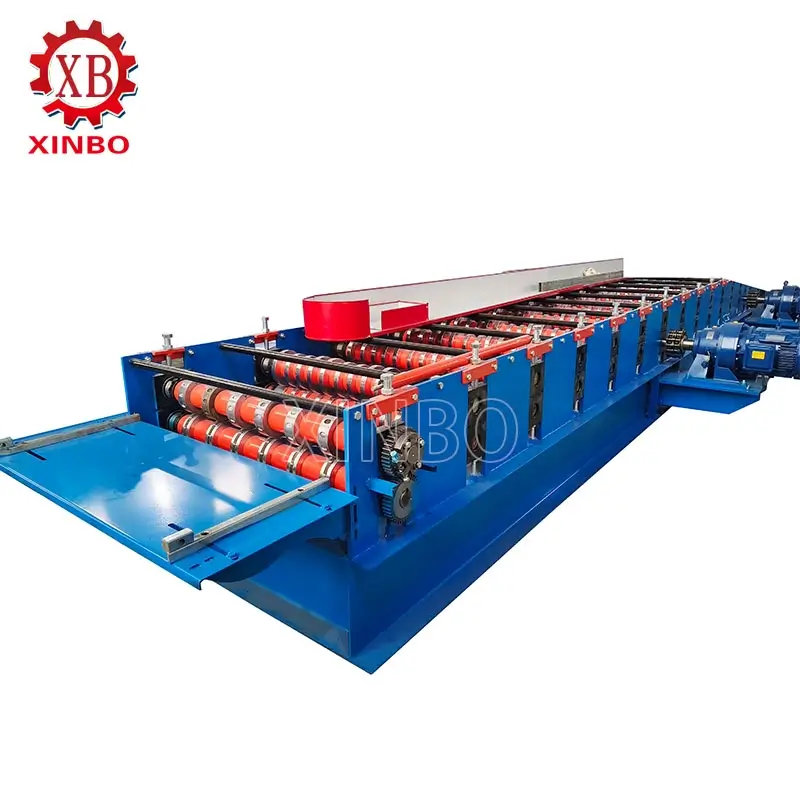

In the quickly changing field of today’s building work, speed and new ideas play a big role in winning. One tool that really helps make making things smoother is the automatic floor decking tile roll forming machine.

This special equipment turns plain steel coils into strong, tough floor decking tiles. People use them a lot in steel structure buildings. No matter if the job involves tall business towers, big storage places, or home projects, learning about the floor deck roll forming machine can change how flooring gets done.

These tools, sometimes called steel floor decking roll forming machines in different situations, get built to create wavy metal sheets. Those sheets act as solid bases for pouring concrete.

А China floor deck roll forming machine, for example, shows a good mix of careful building and growth options. This lets makers meet needs from around the world.

What is an Automatic Floor Decking Tile Roll Forming Machine?

Basic Function

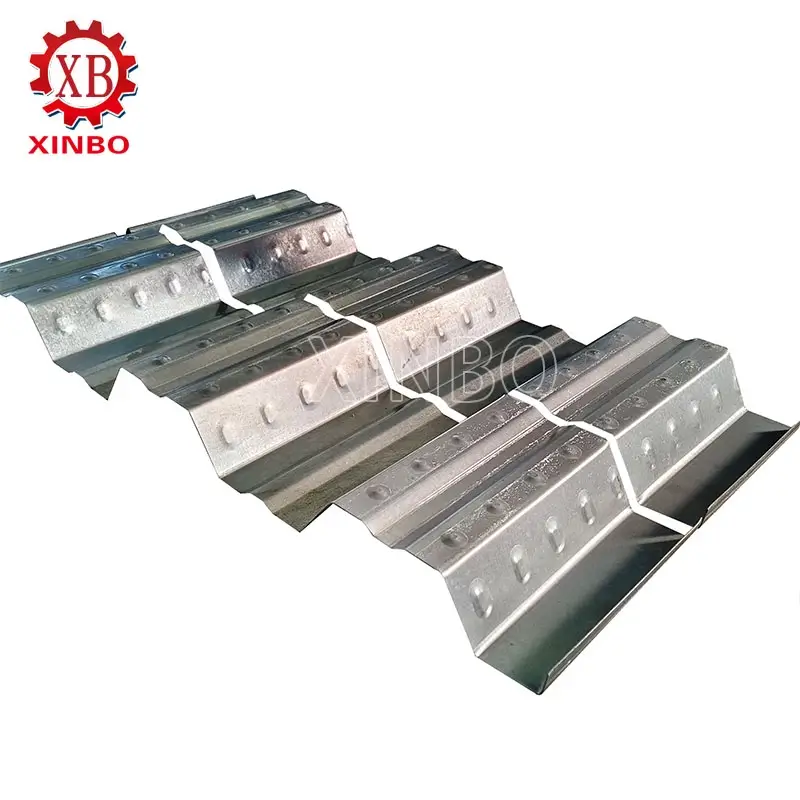

At its basic level, an automatic floor decking tile roll forming machine serves as a steady making line. It builds steel floor decking panels from coated or colored steel coils. Unlike old stamping or pressing ways, roll forming uses many exact rollers. They slowly shape the metal but keep its thickness and power the same. This way makes sure the final tiles—often V-shaped, U-shaped, or trapezoidal types—have better building strength.

Auto Control System

The machine’s auto control stands out as a main part. It links PLC (Programmable Logic Controller) systems for smooth running. From opening the raw stuff to the last cut, each part works together. This cuts down on people working and mistakes. Main parts include:

Decoiler: Keeps and sends the steel coil, usually with liquid power growth for firm hold.

Feeding and Leveling Device: Makes the strip straight to stop bending.

Roll Forming Section: A group of 20-30 rollers, built from top-quality No. 45 forged steel, that step by step form the deck shape.

Punching and Embossing Unit: Puts in strengthening lines or openings for shear studs, which helps concrete stick better.

Hydraulic Cutting System: Cuts panels to wanted lengths with errors as small as ±1mm.

Runout Table: Holds and piles done items.

Material and Capabilities

Raw stuff often goes from 0.8mm to 1.2mm thick coated steel with strength levels of 235-450 MPa. Making speeds can hit 10-25 meters per minute. This gives panels up to 600-1000mm wide. For those wanting special fits, choices like OEM floor deck roll forming machines let changes in shapes to fit job needs, such as taller ribs for bigger weights.

This tech focuses on more than just making things. It aims for exactness. The rollers get digital control to keep even wave length and height. This leads to panels that join very well with concrete. It lowers the want for extra supports.

How Does a Floor Deck Roll Forming Machine Work?

Step 1: Coil Loading

The working of a floor deck roll forming machine acts like a blend of machine parts and electric control. It changes raw coils into set-up-ready tiles in less than a minute for each panel. Let’s split it into steps for a better view.

First, the steel coil—often 5-10 tons heavy—gets put on the decoiler. Liquid arms grow to grab the inside size (usually 508mm). And the coil opens as the line moves forward.

Step 2: Leveling

The strip then goes through guide rollers into the leveling tool. There, top and bottom rollers push evenly to smooth any bends from rolling.

Step 3: Roll Forming

Next arrives the main part of the machine: the roll forming mill. Here, the plain strip meets a row of shaped rollers. Each set adds a small curve. Together, they build the deck’s special waves. For instance, in a normal setup, the start rollers begin the trapezoidal ribs. Later ones add raised marks for stronger hold with concrete. This slow change stops stress spots that might harm the steel.

Halfway, the punching spot turns on. Motor-driven tools make exact holes or cuts for fixing shear links. These are key for joined action in floor setups. Auto control makes sure punches line up just right with the forming, even at fast speeds.

Step 4: Cutting

At last, the shaped panel gets to the cutting shear. Liquid tubes push blade tools to slice the ongoing sheet into lengths from 1-12 meters. This follows PLC commands. Sensors spot the coil end. They start a short stop to skip bad cuts. The done tiles move out onto a liquid or roller table. They are set for packing.

Key Benefits of Automatic Floor Decking Tile Roll Forming Machines

Top Efficiency and Speed

Old floor deck making needs lots of hand work for cutting and bending. It often stays at 5-10 panels each hour. But an auto type pushes out 20-50 meters per minute. This lets one line make thousands of square meters every day.

Good Cost Savings

By skipping steel forms or lots of joining, these tools cut waste stuff by up to 15%. Power use stays low—around 15-22 kW—due to motor parts and good liquid systems.

High Product Quality

The cold-shaping way keeps the steel’s flex and strength. It creates panels with tall wave heights (up to 75mm) for best weight spread. Raised surfaces boost concrete link. This stops sliding during pours. Shapes follow world rules like ASTM A653. They promise lasting power against rust and shakes.

Flexible Use and Changes

Not every job matches one form. With part-based builds, switches in shapes happen via fast-tool changes. For example, from 51mm deep ribs for factory floors to lower ones for bridges. Buy customized floor decking roll forming machines fit to your coil size or speed wants. Add extras like in-line coloring for weather protection.

Green Building Gain

Steel decking from these tools is 100% reusable. It fits with eco marks like LEED. Lighter panels (cutting concrete amount by 20-30%) mean less moving pollution and base weights. This helps earth-friendly jobs.

Better Safety and Simple Use

Auto controls lower worker risks. Easy builds cut tiredness. Screen touches let basic users set runs. This opens high making to more people.

Applications of Steel Floor Decking Produced by Roll Forming Machines

Commercial and High-Rise Buildings

In tall towers, steel floor decking works as lasting form for joined slabs. Poured concrete links with the deck’s ribs. It makes a single floor that covers longer spaces without supports—up to 4 meters free. This quickens building by 30%. It matters for city schedules.

Industrial Warehouses and Factories

For large areas in storage spots, deep-rib shapes (e.g., 200mm height) take heavy moving loads like lift trucks (up to 5 kPa). The deck’s fire hold (rated 1-2 hours) and sound cut make it great for making floors.

Residential Developments

In many-home units, lighter decks lower fixed weights. They allow thinner supports and more space up. They fit modular building. Pre-shaped panels fit fast. This cuts site work.

Инфраструктурные проекты

Bridges and car parks gain from coated decks that fight road salts. Raised surfaces give slip hold. This boosts walker safety.

Roofing and Retrofit Applications

Lower shapes work as roof decks. They hold warmth layers and covers. In fixes, they cover old slabs. They add power without tearing down.

Around the world, want grows in new markets. There, China floor decking roll forming machines drive building growth. These uses highlight how one tool can aid varied jobs. From green homes to huge builds.

Choosing the Right Floor Deck Roll Forming Machine: Tips for Buyers

Picking an automatic floor decking tile roll forming machine means matching wants with details. Begin by checking output: for small places, 10m/min works; big plants want 25m/min. Look at stuff fit—make sure rollers take your coil’s thickness and cover.

Focus on auto grades: Simple types give hand changes. Top ones have IoT for far checks. Seek CE/ISO marks for trust. Money-wise, start units come at fair costs. But add tool fees for special shapes.

Talk to a trusted floor deck roll forming machine manufacturer for shows and tests. Seek strong help after sale, with extra parts ready. In the end, the top pick fits your making aims. It ensures easy fit into work flows.

Часто задаваемые вопросы

Q: What materials are compatible with an automatic floor decking tile roll forming machine?

A: Mostly coated or pre-painted steel coils from 0.5-1.2mm thick, with strength levels up to 450 MPa. Aluminum choices exist for lighter jobs.

Q: How fast does a steel floor decking roll forming machine operate?

A: Speeds go from 10-25 meters per minute. This depends on shape details and auto grade.

Q: Can I customize profiles on a floor deck roll forming machine?

A: Yes, most types allow quick tool switches for V, U, or trapezoidal forms. They suit job needs.

Ready to Elevate Your Production with XINBO’s Expertise?

Learn how ХИНБО‘s cutting-edge automatic floor decking tile roll forming machines can improve your work. As a reliable leader since 2014, we focus on fresh answers for the building field.

Reach us now for a free talk and price. Let’s shape the future as a team—your job needs XINBO quality!

Связанные посты

Хорошее качество

XinBo машина, делающая CO. LTD является профессиональным производителем и экспортером в машине для формирования рулона,

ПРОСМЕТЬ БОЛЬШЕ→

Испанский

Испанский Россия

Россия