The Benefits of Using a U Track Roll Forming Machine for Structural Framing

Введение

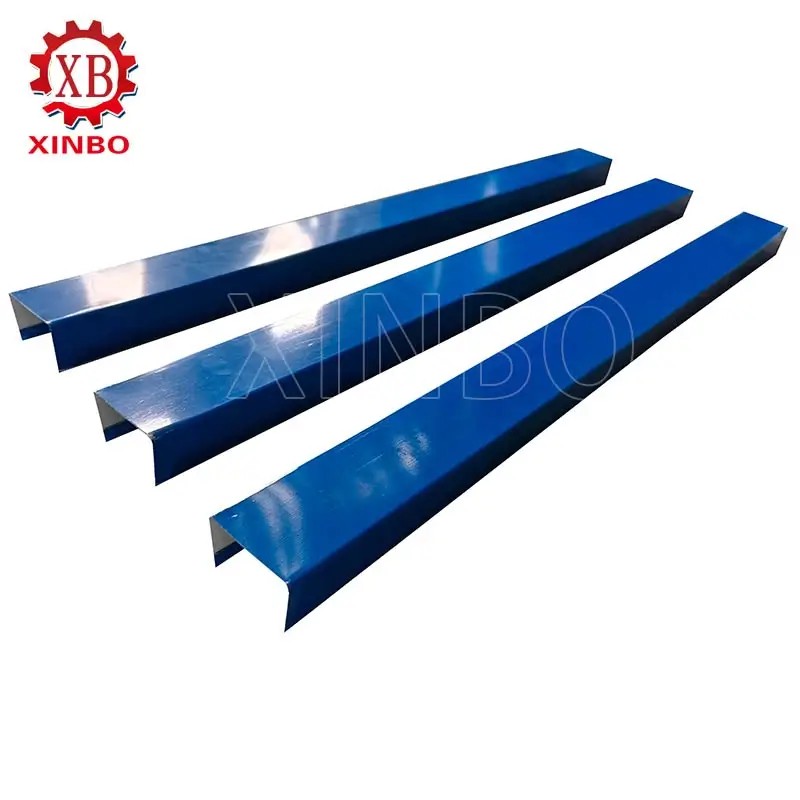

In today’s construction world, speed, accuracy, and flexibility are super important. A key part in drywall framing and partition systems is the U Track. It’s a U-shaped metal channel that gives horizontal support for vertical studs. Making these parts fast and right is crucial for big construction jobs. A U Track Roll Forming Machine offers an easy way to make these vital profiles. Roll forming machines are used a lot in many industries to create top-notch, budget-friendly metal products.

What is a U Track Roll Forming Machine?

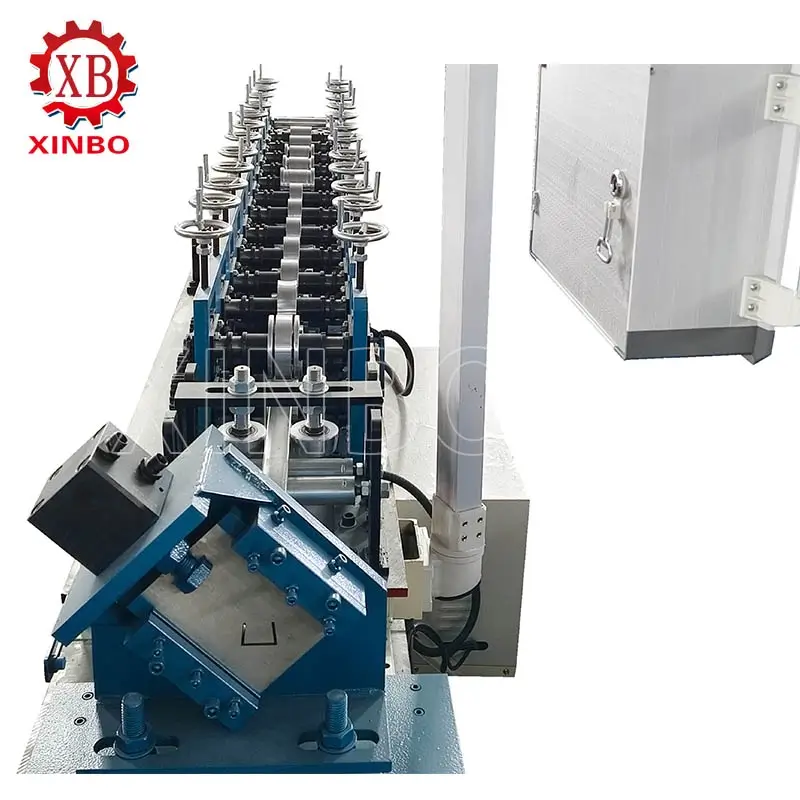

A U Track Roll Forming Machine is a special tool for making U-shaped metal tracks from flat steel coils. These tracks are mostly used as top and bottom runners in wall framing, especially in light gauge steel buildings. This machine builds U-shaped tracks that act as the horizontal base for stud partitions, working with vertical C Studs. It can be set up to make different sizes and thicknesses of U Tracks based on project needs.

There are two main types of machines:

- Single-Profile Machines: Made to produce one specific size and thickness.

- Multi-Profile Machines: Able to switch to different sizes with little downtime.

These machines are key in modern construction. They make accurate and strong parts every time.

U Track Roll Forming Machine Принцип работы

The main idea of a U Track Roll Forming Machine is its steady bending process. Unlike stamping or pressing, roll forming shapes metal slowly through many roller stations without heat. It starts with a flat steel strip, often galvanized to resist rust. The strip is fed from a decoiler into the machine. Each roller station bends the metal a bit more until it forms the final U-shaped profile.

Ключевые части включают:

- Progressive Bending: Makes sure all units are shaped evenly.

- Continuous Operation: Allows fast production.

- Integrated Punching/Cutting: Can add notching or hole punching before cutting to length.

This method ensures accuracy and speed, perfect for making lots of tracks.

U Track Roll Forming Machine Компоненты машины

A typical U Track Roll Forming Machine has several systems that work together smoothly:

- Декойлер: Unrolls the steel coil and feeds it into the machine.

- Feed System: Keeps the metal lined up and tight during processing.

- Ролл формируя секцию: Has many roller stations (usually 10–20) with top and bottom rollers. These shape the steel into a U profile.

- Punching/Notching System: Adds holes or slots if needed.

- Система резки: Cuts tracks to the right length using flying shear or stop-and-cut methods.

- Stacking System: Collects finished tracks for packing or shipping.

- Control Panel: Lets operators control speed, sizes, and safety features with digital screens.

These parts make production smooth, from raw steel to finished U Tracks, with little human effort.

U Track Roll Forming Machine Приложения

U Tracks made by roll forming machines are used in many ways across different fields:

- Жилое строительство: For inside walls, ceilings, and sometimes outside partitions.

- Коммерческие здания: In offices, malls, and warehouses for partition framing.

- Промышленные объекты: Used in curtain walls and overhead door frames.

- Modular Construction: Pre-made units need exact track sizes.

- Agricultural Buildings: Light but strong framing for barns or greenhouses.

Their flexibility makes them essential for both permanent and temporary structures.

U Track Roll Forming Machine Преимущества

Using a U Track Roll Forming Machine brings lots of perks:

- Высокая скорость производства: Machines can run at speeds up to 100 feet per minute.

- Точность и последовательность: Automatic rollers make every unit match exact specs.

- Material Efficiency: Steady work cuts waste a lot.

- Labor Savings: Automation reduces the need for workers.

- Универсальность: Multi-profile options allow quick switches between track sizes.

- Продолжительность: Galvanized steel tracks resist rust well.

- Customization: Machines can be set for unique building needs or local standards.

These benefits make them a smart choice for manufacturers aiming for high output with few errors.

Workflow или U Track Roll Forming Machine

The production process with a U Track Roll Forming Machine follows a clear path:

- Manual Decoiler: Steel coils are placed on a decoiler. It unrolls material into the feed system.

- Платформа кормления: Lines up the material before it hits the rollers.

- Main Roll Forming Unit: Shapes steel step by step through multiple stages.

- Automatic Cutting System: Cuts profiles at set lengths.

- Hydraulic Station & Control Box: Powers the machine and controls things like speed and profile size.

- Finished Panel Receiving Table: Collects completed tracks for packing or delivery.

This clear process ensures high output with little downtime or mistakes.

Future Trends или U Track Roll Forming Machine

As technology grows, new trends are coming for roll forming machines:

- Increased Automation: Robots may soon handle loading and unloading tasks fully.

- Smart Monitoring Systems: IoT will allow machines to predict maintenance needs with real-time data.

- Sustainable Manufacturing: Using recycled materials fits with eco-friendly building goals.

- Energy Efficiency Enhancements: Cutting energy use is a big focus for machine design.

- Advanced Customization Software: New tools will make complex profiles without big mechanical changes.

These updates will boost productivity and support green goals worldwide.

Custom U Track Roll Forming Machine from XinBo

Синбо is a top manufacturer offering custom roll forming машины solutions since 2014. XinBo machine is a manufacturer which established in China since 2014. The company focuses on building machines to meet customer needs while following global standards like CE certification.

Our factory has skilled engineers and designers. They can create detailed drawings fast to match customer needs. We also have our own workshop with CNC machining and workers. This saves costs and keeps the process on track.

All XinBo machines are checked three times before shipping. We design and machine parts ourselves. This ensures fast delivery of machines that fit your needs. With exports to Europe, Canada, South America, Africa, and the Middle East, XinBo is a great partner for custom roll forming solutions that meet global standards. We work hard to meet all customer needs.

Часто задаваемые вопросы

What materials can be used in a U Track Roll Forming Machine?

Most often, galvanized steel coils are used. They’re strong and resist rust, perfect for structural jobs.

Can I customize my machine?

Yes. Our expert design team will build the machine to fit your exact needs.

How long does delivery take?

Thanks to our CNC machining setup, we design and build machines ourselves. This ensures fast delivery.

Are these machines easy to operate?

Yes. Modern control systems have touchscreen panels. They make operation easy, even for less-skilled workers.

Do you provide after-sales support?

Yes. We offer guaranteed quality products and full service, including design, assembly, installation, and after-sales support.

Связанные посты

Хорошее качество

XinBo машина, делающая CO. LTD является профессиональным производителем и экспортером в машине для формирования рулона,

ПРОСМЕТЬ БОЛЬШЕ→

Испанский

Испанский Россия

Россия