What Is a Container House Corner Post Roll Form Machine and How Does It Work?

What is a Container House Corner Post Roll Form Machine?

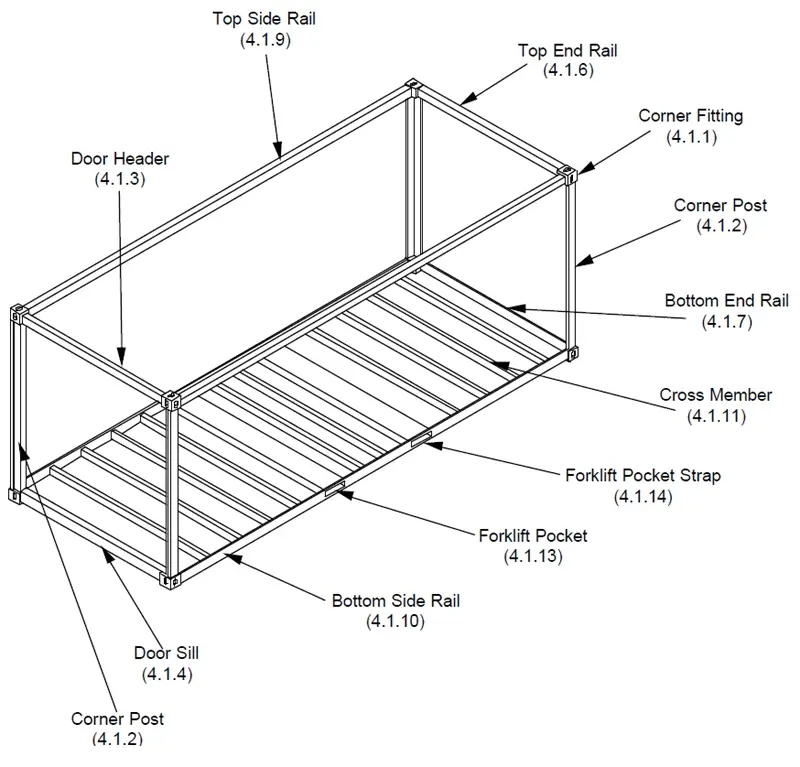

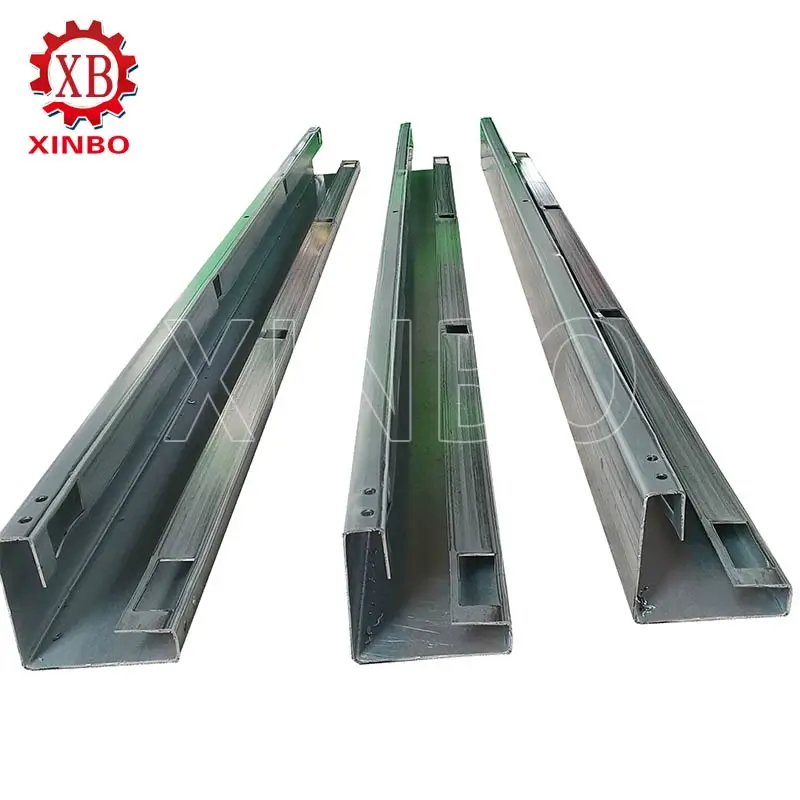

A Container House Corner Post Roll Form Machine is special equipment for making corner posts. These posts are key for building container houses and modular structures. They act as strong vertical supports. The machine shapes exact metal profiles for stability and connection in container homes. These homes are prefab units, often made from shipping containers or built new for homes, shops, or factories.

The machine uses cold roll forming technology. It bends metal coils step by step without heat. This keeps the material strong and tough. The corner posts help with structural integrity, easy transport, and stacking multiple container units.

How Does Container House Corner Post Roll Form Machine Work?

The machine works through a cold roll forming process. It turns flat metal coils into finished corner post shapes. The process begins with a decoiler. It holds a coil, usually galvanized or carbon steel, 2.0mm to 3.0mm thick. The decoiler unwinds the coil smoothly to keep feeding steady.

Next, the metal strip goes through a leveler. This flattens any curls. Then, a hydraulic punching unit adds slots or holes for fastening. The main part is the roll forming section with 18 to 20 roller stations. Each station bends the metal a bit more until it forms the final shape.

After forming, a hydraulic cutting unit cuts the profile to set lengths. A programmable logic controller (PLC) system runs everything. It ensures precision and cuts errors. The cold forming method saves energy and avoids warping the metal.

Key Components of Container House Corner Post Roll Form Machine

The machine has several parts that work together for precision and strength:

-

Декойлер: Holds coils up to 5 tons. It fits coils with inner diameters of 480-520mm and outer diameters up to 1250mm. It unwinds smoothly to avoid tangles.

-

Leveler: Uses rollers to flatten the metal strip. This prevents defects in the final post.

-

перфорационный блок: A hydraulic system with strong steel dies (e.g., Cr12MoV). It punches holes or slots, powered by an 11KW pump, synced with the control system.

-

Система формирования рулона: Has 18-20 stations with rollers on 80mm shafts made of 45# steel. Rollers use GCr15 bearing steel, hardened to HRC58-62 for long life. The frame is welded from sturdy plates. Chains or gears, driven by a 15-18.5KW motor, move the system.

-

Cutting Unit: A hydraulic cutter with Cr12MoV dies cuts cleanly. It stops briefly for exact cuts to match container designs.

-

Система управления: Uses a PLC, inverter, transformer, and encoder. It controls speed (0-12m/min), monitors tasks, and allows adjustments. Safety features make it easy to use.

-

Hydraulic System: Powers punching and cutting with an 11KW pump for steady pressure.

-

Таблица выхода: Collects finished posts. It extends for longer profiles and helps with stacking.

Extra features like safety covers, aviation plugs, and a strong base ensure safe and stable operation. The machine takes up about 15,000mm x 1,200mm of space, fitting factory settings.

Workflow/Process Steps of Container House Corner Post Roll Form Machine

The workflow is a smooth, automated process for fast production:

-

Material Preparation and Loading: Load a steel coil (galvanized or carbon, 2-3mm thick) onto the decoiler. Secure it to avoid slipping and align it with the feed path.

-

Uncoiling and Leveling: The decoiler unwinds the strip slowly. It goes through leveling rollers to remove curls and stresses.

-

Punching/Pre-Processing: The strip enters the punching unit. It stops briefly to stamp holes or slots, programmed for the post’s design.

-

Формирование рулона: The strip moves through 18-20 stations. Early stations start curves, middle ones shape angles, and final ones finish the corner post profile. Speed stays at 10-15m/min with constant checks.

-

Cutting to Length: Sensors spot the right length. The hydraulic cutter makes a clean cut, keeping waste low.

-

Output and Inspection: Posts land on the output table. Workers check for flaws and measure sizes before stacking.

-

Control and Monitoring: The PLC system keeps everything in sync. It adjusts for thickness and stops if issues arise, ensuring quality.

Applications of Container House Corner Post Roll Form Machine

These machines are key in modular construction. They make parts for many structures:

-

Residential Container Homes: Corner posts form frames for portable bedrooms, tiny homes, or multi-unit houses. They allow quick setup and takedown.

-

Commercial and Office Spaces: Used for offices, stores, or pop-up shops. Posts support multi-story builds with slots for wiring or plumbing.

-

Industrial and Utility Structures: Posts make enclosures for equipment, storage, or restrooms, tough enough for harsh sites.

-

Transportation and Logistics: Posts are used in shipping containers for securing cargo on ships, trucks, or trains.

-

Specialized Modular Builds: Used in hotels, apartments, food courts, or beer gardens. In wildfire areas, non-combustible posts add safety.

Advantages of Container House Corner Post Roll Form Machine

These machines have many benefits:

-

High Efficiency and Speed: Produces up to 15m/minute.

-

Точность и последовательность: Exact shapes ensure perfect fits.

-

Экономия материалов: Low waste from smart design.

-

Эффективность затрат: Cold forming saves energy. Automation cuts labor costs.

-

Customization: Rollers adjust for different profile designs.

-

Продолжительность: Posts handle up to 116 kips per corner in stacked setups.

-

Экологические преимущества: Prefab cuts onsite waste.

Materials Used and Maintenance Considerations

The machines use galvanized steel for rust resistance or carbon steel for cost. Thicknesses of 2mm–3mm balance strength and flexibility.

Maintenance includes:

-

Regular oiling of moving parts.

-

Checking hydraulic systems.

-

Calibrating controls.

Good care keeps machines running for decades.

Comparisons with Other Forming Methods

Compared to press braking:

-

Roll forming is faster for long runs.

-

It gives more even shapes.

Compared to extrusion: -

It works with strong metals at room temperature.

-

It skips costly dies needed for extrusion.

These make it great for corner posts.

Custom Your Container House Corner Post Roll Form Machine from XinBo

Синбо started in 2015, makes custom roll forming machines to fit client needs. They design machines for all kinds of requests.

XinBo’s team builds every part, from decoilers to control boxes, to European CE standards. Their machines have smart designs and updated tech. XinBo offers full support, including design help (ODM/OEM), installation, and after-sales service. They provide guaranteed quality products with one-stop service.Свяжитесь с XinBo for instant quote.

Связанные посты

Хорошее качество

XinBo машина, делающая CO. LTD является профессиональным производителем и экспортером в машине для формирования рулона,

ПРОСМЕТЬ БОЛЬШЕ→

Испанский

Испанский Россия

Россия