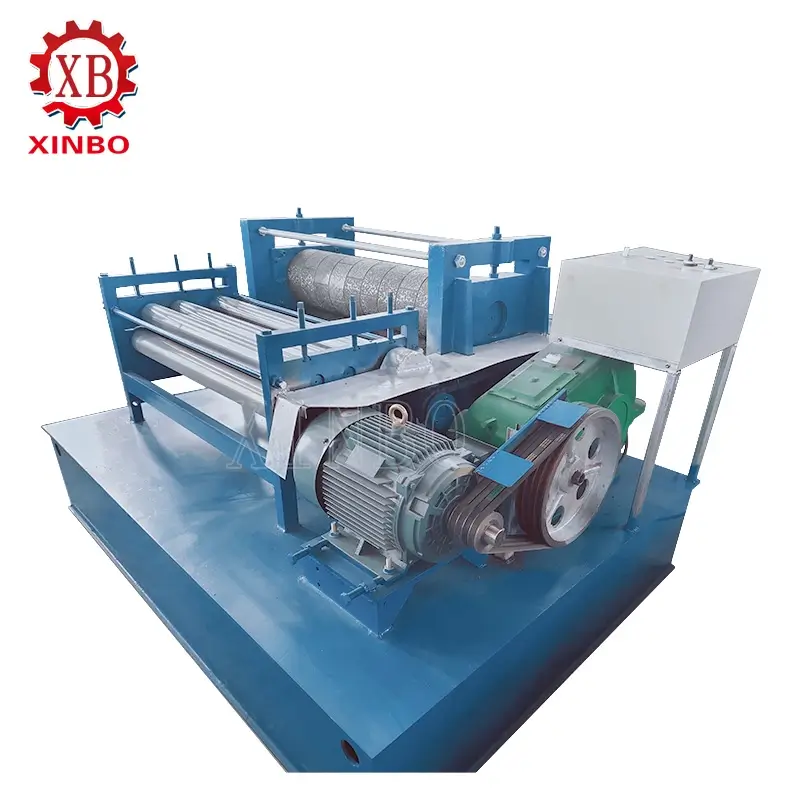

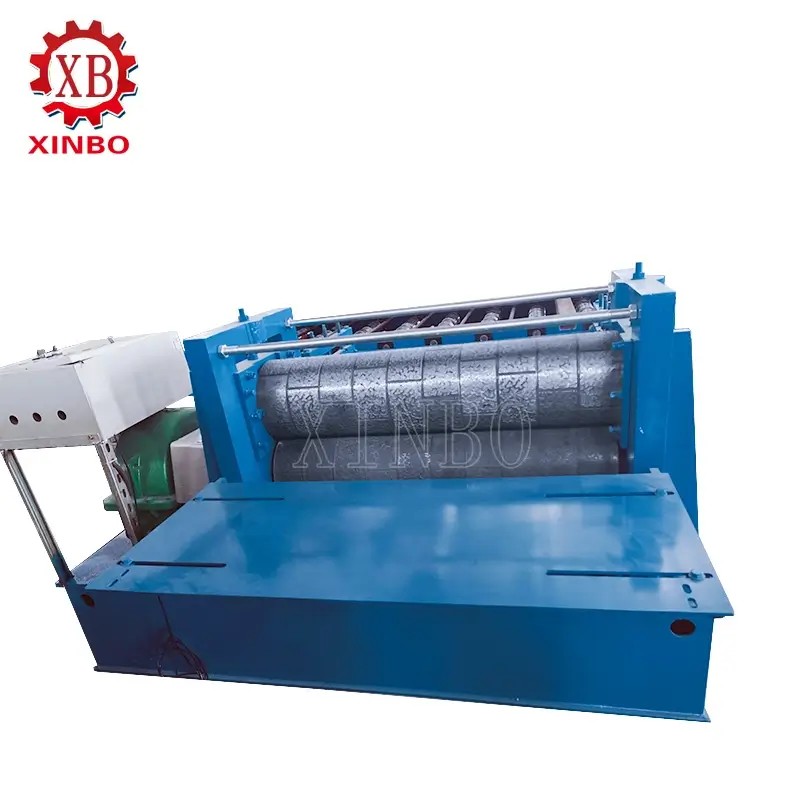

XINBO: Leading Automatic Sheet Metal Embossing Machine Supplier in China

Introduction: Where Precision Meets Artistry

In the busy field of metal work, where careful accuracy blends with creative skill, the automatic sheet metal embossing machine serves as a key tool for new ideas.

For anyone looking for an embossing machine for metal sheet, a trusty sheet metal embossing machine, or a high-level embossing machine for sheet metal, knowing this tech is very important.

These tools turn plain metal sheets into bumpy works of art. And they boost both use and beauty. As a main spot for China sheet metal embossing machine companies and China sheet metal embossing machine supplier know-how, China keeps leading the world market. It offers top-notch answers like the metal frame sheet embossing machine China types and wholesale metal frame sheet embossing machine choices.

What Is an Automatic Sheet Metal Embossing Machine?

Deep down, an automatic sheet metal embossing machine is a special device built to make lifted or sunken shapes on metal sheets by using steady pressure.

Unlike hand stamping that needs people power, auto kinds use water, air, or motor-driven setups for steady, big-amount results.

The steps include putting a metal sheet—usually steel, aluminum, stainless steel, or copper—between two carved rollers. One is male (lifted) and one is female (sunken). As the sheet moves through, the rollers put even force. This bends the stuff to print detailed designs like diamond patterns, checker plates, stripes, or own logos.

This tech started back in the factory boom time. But it has grown a lot with auto features.

Today’s sheet metal embossing machines can deal with thicknesses from 0.5mm to 6mm and widths up to 2000mm. So they fit everything from slim pretty panels to strong build parts.

The “automatic” part means PLC (Programmable Logic Controller) links. These handle feeding, embossing, and rolling back—cutting down worker help and fewer mistakes.

For example, in a normal setup, a decoiler opens the metal coil. It sends it into the embosser. Then a recoiler grabs the done item—all timed by sensors for smooth work.

Why It Matters: The Strength Behind the Style

Embossing is not only for looks. It adds build strength by making things stiffer and better grip on top.

A plain sheet may bend under weight. But an embossed one spreads stress the same way. This makes it last longer.

In fields that care about embossing machine for sheet metal speed, these tools give output rates of 10–30 meters per minute. That beats hand ways by far.

How Does a Sheet Metal Embossing Machine Work?

Feeding Mechanism

Motor-driven feeders or belt paths move the sheet at set speeds.

Speed changers make sure no slips, even on greasy tops.

Embossing Action

The sheet goes into the tight spot between rollers.

Water cylinders or link parts put pressure up to 100 tons—set by CNC controls for shape depth (usually 0.5–2mm).

Laser-cut rollers pass the design with exact care and long life.

Post-Processing

After embossing, the sheet goes through cool or straight units to fix the shape and stop bends.

In full work lines, it rolls back for keeping or cuts to size on its own.

Technical Highlights

Roller Diameter: 450–500mm for lasting strength

Frame Material: Welded Q235 steel plates (90mm thick) for shake resistance

Аутоматизација: Digital screens for one-key mold switches

Safety: CE and UL-certified quick stops and overload sensors

Water systems give raw power for thick sheets. Air systems bring fine touch for soft designs.

Power-smart changers cut energy use by 20–30%. This makes these tools a green pick in today’s making.

Benefits of Using an Automatic Embossing Machine for Sheet Metal

Прецизност и конзистентност

Motor controls make sure even depth over big areas. They remove flaws often seen in hand ways.

This exactness raises good rates by 15–20%, bettering output level and money gains.

Enhanced Functional Properties

Bumpy sheets get better heat spread, rub resistance, and nice looks.

For instance, diamond patterns boost grip by up to 50%. They suit safety floors and work paths.

Operational Efficiency

Auto cuts work costs—one worker can watch a line making over 1000 sheets daily.

Long life is another plus: tough rollers last 10+ years. And part frames make fixes easy.

Environmental Sustainability

These tools fit green making rules.

Low-scrap steps (almost no waste) and power-save drives lower harm marks—an edge for China sheet metal embossing machine companies fighting in world markets.

Апликације широм индустрије

The wide use of embossing machines for sheet metal covers many areas:

Изградња: Bumpy panels for building fronts, roofs, lift insides, and no-slip floors.

Аутомобил: Heat blocks, edges, and pretty parts.

Appliance Manufacturing: Bumpy stainless-steel panels for fridges and wash machines.

Furniture & Décor: Fancy metal frames and wall art with cloth or wood-look bumps.

Packaging: Bumpy tins and cans with brand lifts for eye catch.

HVAC: Diamond-bumpy tubes for strength and stiff.

For metal frame sheet embossing machine supplier groups, these tools also make strong frames for safe doors, office walls, and work boxes.

Wholesale metal frame sheet embossing machine amounts help shippers turn raw coils into high-value sheet goods for world spread.

Choosing the Right Embossing Machine: Key Considerations

Компатибилност материјала – Make sure rollers fit stainless steel, aluminum, or copper.

Capacity – Match thickness (1–6mm) and width (1000–2000mm) to work needs.

Ниво аутоматизације – Seek PLC-linked lines and fast-switch rollers.

Потврде – Pick CE, TUV, or ISO-checked models.

After-Sales Service – Training, extra parts, and warranty (1–2 years) count.

ODM Options – For buyers getting from China sheet metal embossing machine companies, ODM changes allow laser-cut designs for brand-own ends.

Maintenance Tips for Longevity and Performance

Weekly: Wipe rollers with soft cleaners to stop buildup.

Monthly: Look at water fluid levels and oil bearings.

Quarterly: Set sensors for right bump depth.

Storage: Put tools in dry, covered spots to stop rust.

With steady care, look for 10,000+ work hours. This cuts stop time and boosts return.

FAQ: Sheet Metal Embossing Machines

Q1: What materials can an automatic sheet metal embossing machine process?

They can take mild steel, stainless steel, aluminum, copper, and coated sheets, usually 0.5–6mm thick.

Q2: How does an embossing machine differ from a roll forming machine?

Roll forming makes shapes, while embossing works on top feel. They often join for two jobs.

Q3: What patterns are available?

Diamond, checker plate, stripes, linen, and own logo designs, all exact-cut for long use.

Q4: Is it suitable for high-volume production?

Yes—auto models hit 10–30m/min, perfect for big-scale output.

Q5: How to maintain a metal frame sheet embossing machine?

Usual wipes, water checks, and every-three-month sets keep tools going past 10 years.

Q6: Which industries benefit most?

Construction, automotive, appliance, furniture, and packaging fields gain from China sheet metal embossing machine suppliers due to good level and low cost.

Elevate Your Production: Partner with XINBO – Trusted Manufacturer & Supplier

Ready to change your metal work?

As a top China sheet metal embossing machine supplier and metal frame sheet embossing machine manufacturer, Ксинбо gives fit answers—from own tool plans to wholesale metal frame sheet embossing machine supply sets.

👉 Contact XINBO today for a free talk and price:

Turn plain metal sheets into better, bumpy goods with the exact care, work level, and trust of XINBO’s automatic sheet metal embossing machines.

Сродни постови

Добар квалитет

КсинБо машина која производи ЦО. ЛТД је професионални произвођач и извозник у машини за обликовање ваљака,

ВИЕВ МОРЕ→

Шпански

Шпански Русија

Русија