Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine | IBR Roof Sheet Forming Machine Factory

In today’s busy building world, picking the right tools can change everything. Meet the Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine—a super cool machine that makes strong, awesome roofing sheets fast. If you’re in the roofing business or running a factory, knowing what this machine can do will make your work way better. Let’s check it out!

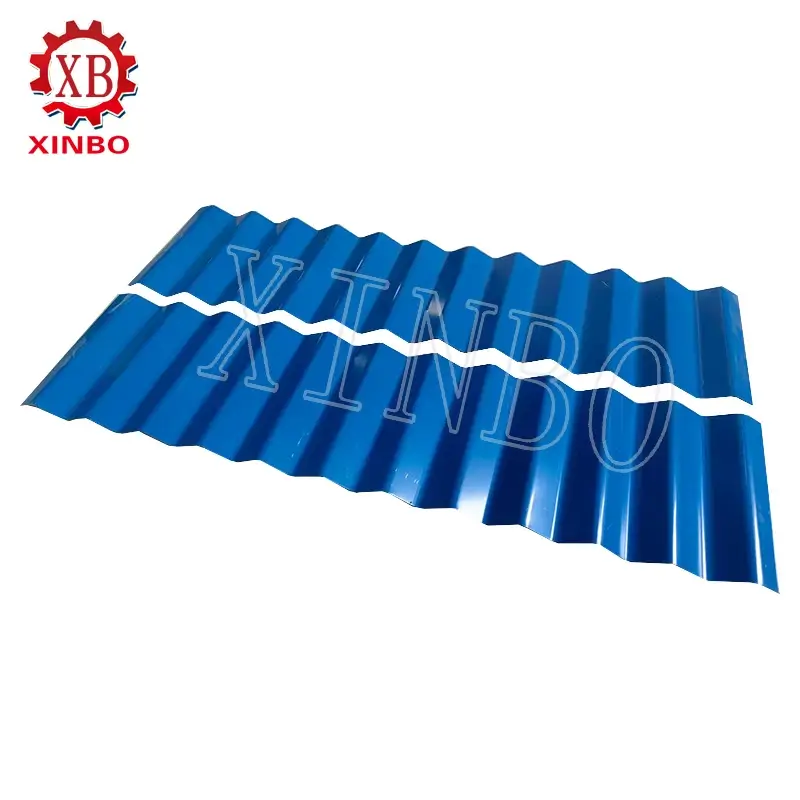

What is an IBR Trapezoidal Roof Sheet?

Understanding the IBR Profile

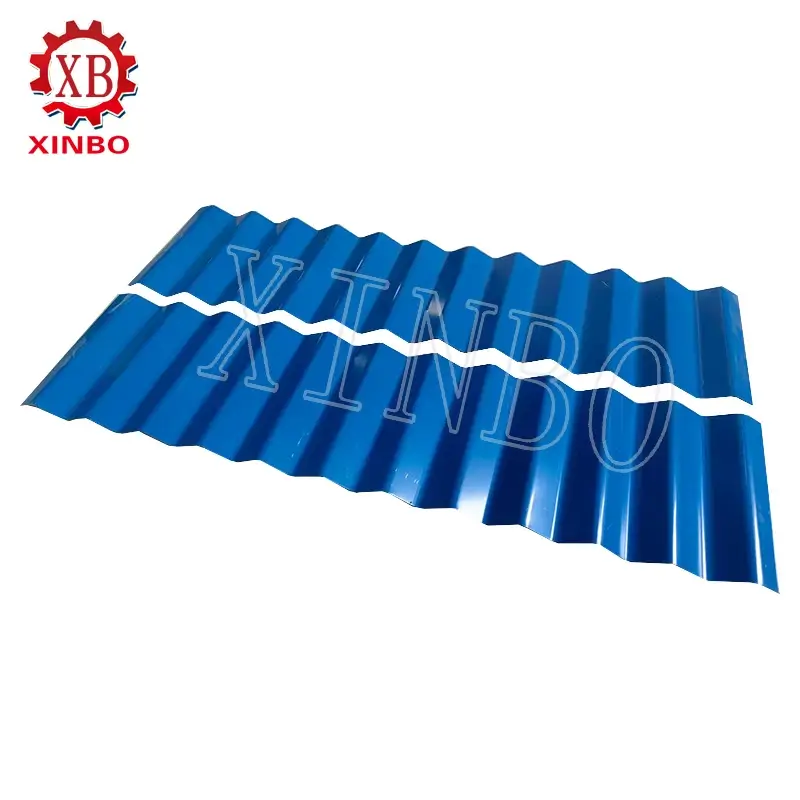

Before we talk about the machine, let’s get the basics down. IBR means “Inverted Box Rib.” It’s a neat trapezoidal shape from South Africa, but now it’s used all over the world. Unlike flat sheets, IBR trapezoidal roof sheets have a wavy pattern with high ribs and flat dips. This look isn’t just pretty—it’s really useful.

Structural and Environmental Benefits

The trapezoidal shape makes sheets super strong. They can cover long spaces without extra supports. Usually made from galvanized steel or aluminum, these sheets fight rust and bad weather. That makes them perfect for roofs in tough places. From a factory view, making IBR sheets needs exact work to keep rib heights (35-42mm) and widths (up to 1,000mm) the same. The Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine does this super well, turning coils into sheets with hardly any waste.

Why Choose Trapezoidal Sheets?

Why go for trapezoidal? The slanted sides spread weight evenly, so leaks are less likely. They also hold up heavy stuff better. In places with lots of rain, like parts of Asia or Africa, IBR sheets are awesome because water runs off easily. If you’re new to roofing, think of them like the trusty pickup truck of metal sheets—dependable, flexible, and not too pricey.

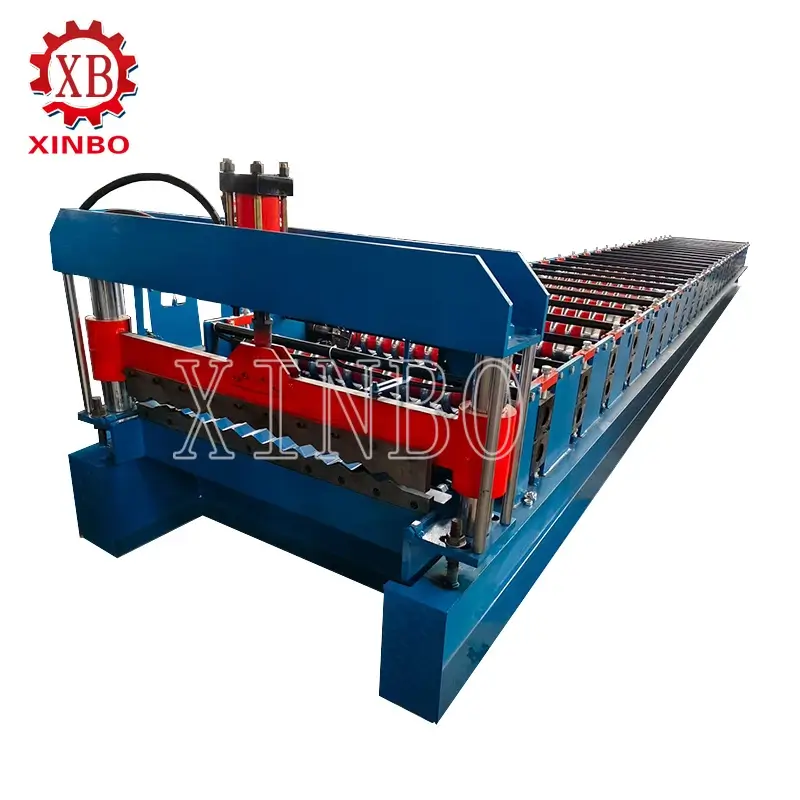

The Mechanics of the IBR Roof Sheet Forming Machine

Основне компоненте машине

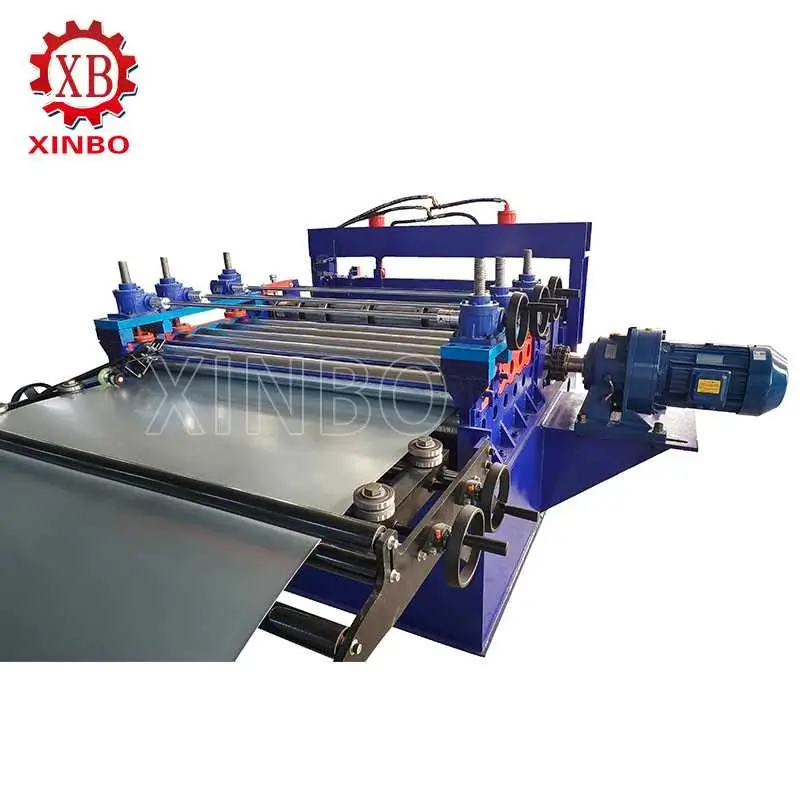

At its heart, a roll forming machine shapes metal by running it through rollers. The IBR Trapezoidal Roof Sheet Roll Forming Machine takes it up a notch with special parts made just for the IBR shape.

Step-by-Step Roll Forming Process

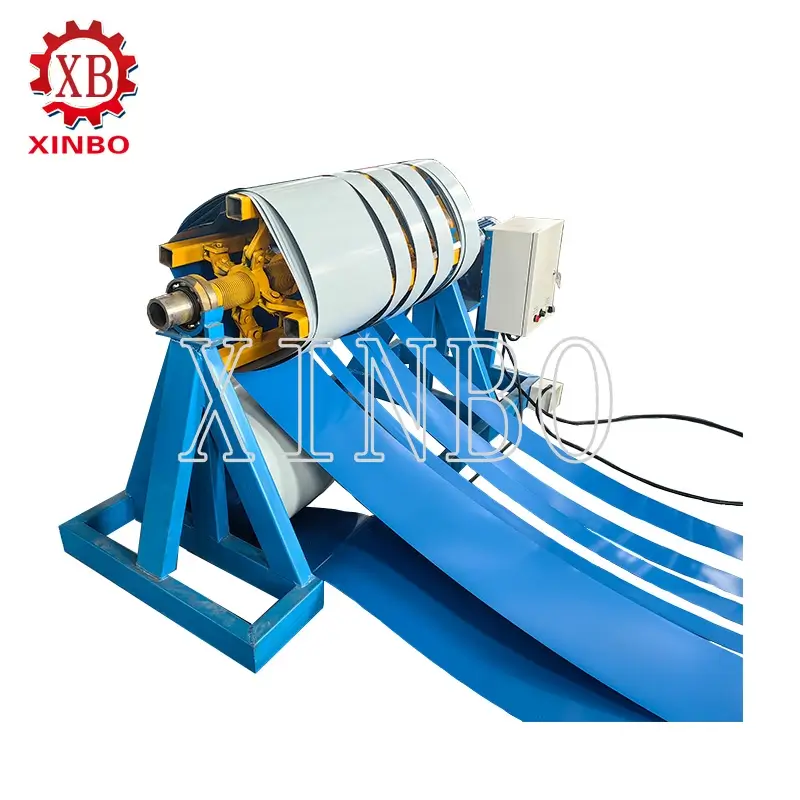

It starts with a decoiler. This unrolls metal coils (0.3-0.8mm thick) into the machine. Next, the sheet gets flattened and punched for any holes or slots you want. The main part is the forming section—15-20 pairs of rollers bend the metal bit by bit into the trapezoidal shape. Each roller pair shapes a specific curve, so the ribs form perfectly without breaking the metal.

Аутоматизација и прецизност

Hydraulic cutters chop the sheet to exact lengths (2m to 12m). Then, a stacker piles the sheets neatly. Cool machines like the Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine use PLC controls to run automatically. You can set speeds up to 15m/min. Safety stuff, like emergency stops and sensors, keeps accidents away, and energy-saving motors keep costs low.

Achieving High-Quality Output

What makes top machines special? Super exact work. They keep tolerances as tight as ±0.5mm, so sheets fit perfectly when installed. That means less fixing on the job site. For factories, this means cranking out up to 10 tons of sheets a day while keeping the “good price and quality” balance that makes them awesome.

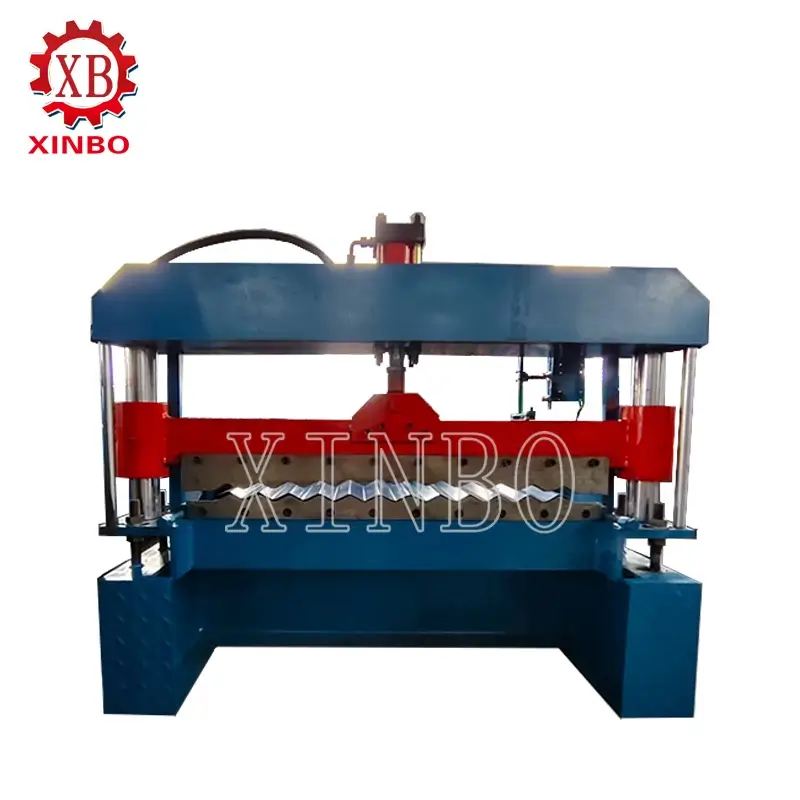

Key Features of a Top-Tier IBR Trapezoidal Roof Sheet Roll Forming Machine

Durable and Modular Design

When picking a machine, features show you what’s good. A great IBR Roof Sheet Forming Machine has a modular setup, so it’s easy to fix. Rollers are made from strong alloy steel, heat-treated to last super long (up to 100,000 hours). This means fewer breakdowns, so your factory keeps running smoothly.

Versatile Profile Capabilities

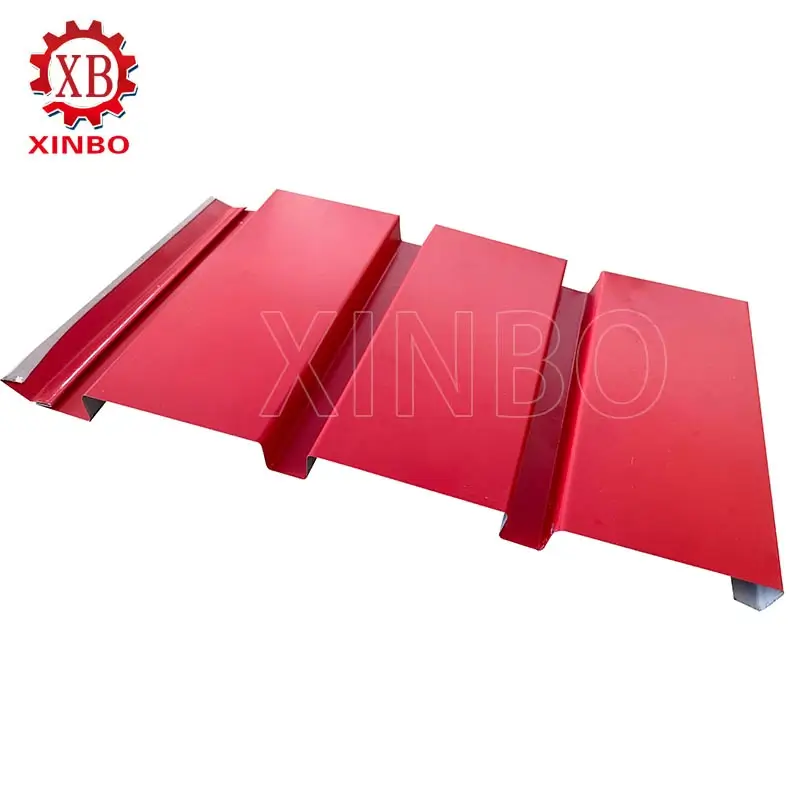

These machines are super flexible. They can switch from IBR to corrugated sheets with quick tool changes. Smart software watches things like thickness and speed, so you can use different materials like color-coated or stainless steel without a hitch.

Energy Efficiency and Noise Reduction

Saving energy is a big deal. Top models use servo motors that need 20-30% less power than old systems, which is great for the planet. They’re also quiet (under 70dB), making the factory a nicer place to work. For those looking at the “good price” part, these machines keep costs low—often under $0.05 per linear foot for big runs.

Прилагођавање за посебне потребе

You can tweak these machines a lot. Add-ons like embossing rollers make sheets non-slip, or auto-stackers save workers’ time. Basically, the Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine isn’t just a tool—it’s a custom fit for growing businesses.

Benefits: Why Invest in an IBR Roof Sheet Forming Machine?

Cost Savings and Reduced Waste

This machine saves you money in tons of ways. Making sheets in-house cuts out extra costs from suppliers, saving 15-25% on materials. The IBR Trapezoidal Roof Sheet Roll Forming Machine makes exact cuts, so there’s less waste. You can even recycle scraps into other products.

Consistent Quality Assurance

Quality you can count on is huge. Hand-bending can mess up sheets, making roofs weaker over time. Automated roll forming keeps every sheet the same, meeting rules like ASTM A653 for galvanized coatings. This makes customers happy and brings them back.

Scalability for Growing Demands

Speed and growth go hand in hand. What took hours by hand now takes minutes. This helps you make sheets just in time for building projects. For exporters, meeting global standards like ISO 9001 opens doors to places like Europe and the Middle East.

Environmental and Long-Term ROI

These machines are great for the planet. They use less water and power than old presses. Plus, recyclable metal means less trash. Money-wise, a mid-range machine pays for itself in 12-18 months by making more sheets with fewer workers (one per shift is enough).

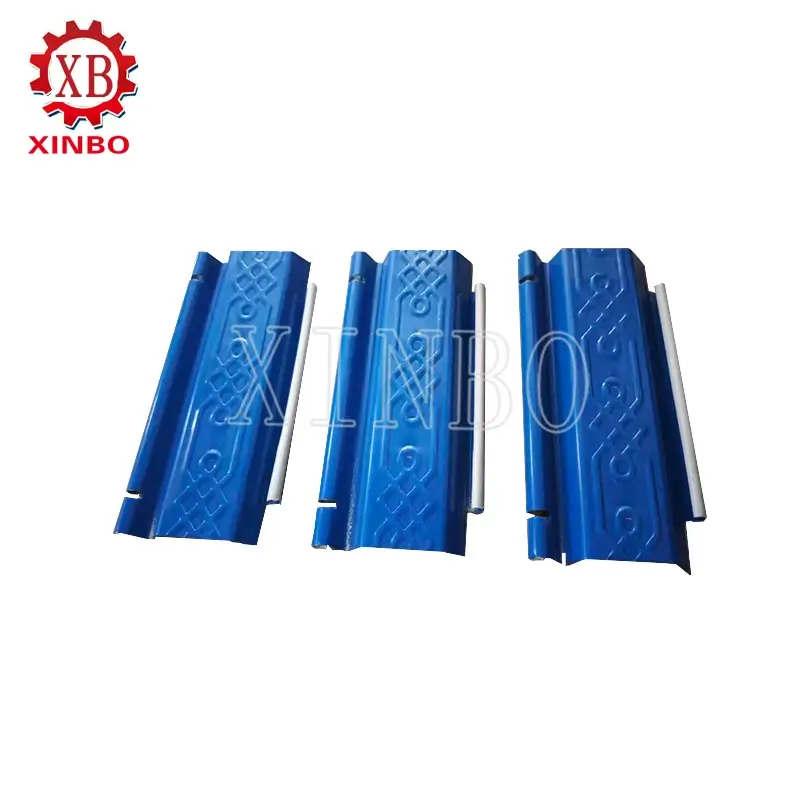

Applications in Modern Construction and Beyond

Residential and Commercial Uses

IBR trapezoidal sheets aren’t just for roofs—they’re super versatile. In homes, they cover suburban houses, looking sleek with insulation for cozy living. In businesses, they’re used for warehouses and factories, handling heavy stuff like solar panels over wide spans (up to 10m).

Agricultural and Disaster-Relief Solutions

Farmers love them for barns and silos. The shape shakes off rain and snow, keeping animals and crops safe. In disaster areas, IBR sheets make quick shelters because they’re light (4-6kg/m²) but tough.

Industrial and Emerging Trends

They’re also used for cladding offices, retail facades, or even curved stadium roofs. With prefab building on the rise, the IBR Roof Sheet Forming Machine lets you customize on-site, speeding up modular homes. New trends? Green roofs use IBR for drainage under plants. In city farming, these sheets make frames for hydroponic greenhouses. In growing economies, IBR is a hit for affordable housing.

Choosing the Right IBR Trapezoidal Roof Sheet Roll Forming Machine for Your Factory

Matching Capacity to Needs

Start with capacity: Match coil width (686mm standard for IBR) to how much you need to make. Budget-wise, starter models are affordable, but pick CE-certified ones for safety.

Space and Vendor Support Considerations

Check your space: A small footprint (10x2m) works for tiny factories, while bigger frames fit growth. Pick vendors with 24/7 parts support to keep things running.

Importance of Test Runs and Warranties

Test runs show how good a machine is—ask for demos. Also, look for warranties (1-2 years) and training. The Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine should fit your work, not control it.

ФАК

What makes IBR trapezoidal roof sheets superior to other profiles?

IBR’s inverted rib design spans farther and drains better, perfect for big roofs with fewer supports.How fast does an IBR Roof Sheet Forming Machine operate?

Speeds hit 8-20m/min, depending on thickness and automation.Is the machine suitable for beginners?

Yes, with PLC controls and training, one worker can handle it easily.What materials work best with this roll forming machine?

Galvanized steel, aluminum, and color-coated coils up to 0.8mm thick.How does it ensure quality at a good price?

Exact rollers and automation cut waste, balancing low cost with strong output.

Partner with XinBo for Your Roll Forming Needs

Ready to level up with a Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine? Since 2014, КсинБо has been a go-to name for cool metal shaping tools, with over 10 years of know-how. Our machines meet UL, CE, and ROHS standards, backed by awesome ODM/OEM services. From Europe to Canada, factories trust us for great performance and fast delivery.

Контакт XinBo today via WhatsApp at +86 150 0321 6790 or visit www.cnXinBo.net to check out our machines. Let’s build the perfect roofing solution for your business—your success starts now!

Сродни постови

-

High-Quality Roll Shutter Door Roll Forming Machine: Efficient and Reliable

-

Simple Metal Coil Slitting Line Wholesale: High Precision Rolling Stainless Steel Coil Strip Slitting Machines

-

Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine | IBR Roof Sheet Forming Machine Factory

-

Advantages of Using High-Speed Automatic Steel Coil Slitting Lines | Steel Coil Slitting Line Manufacturer

-

Best architectural Metal siding cladding wall panel roll forming machine for sale:Boost Your Wall Decoration Business

-

How to Choose the Best EPS Sandwich Roof Panel Production Line Machine for Your Business

Добар квалитет

КсинБо машина која производи ЦО. ЛТД је професионални произвођач и извозник у машини за обликовање ваљака,

ВИЕВ МОРЕ→

Шпански

Шпански Русија

Русија