Z-Shaped LED Strip Metal Profile Roll Forming Machine for Ceiling and Wall Decoration

Giriş

Today’s building designs often use LED strip lights for indoor spaces, like ceilings and walls. These lights need Z-shaped LED strip metal profiles to look good and work well. Also, these profiles protect the lights and make them last longer. Roll forming machines help make these profiles quickly and in large amounts.

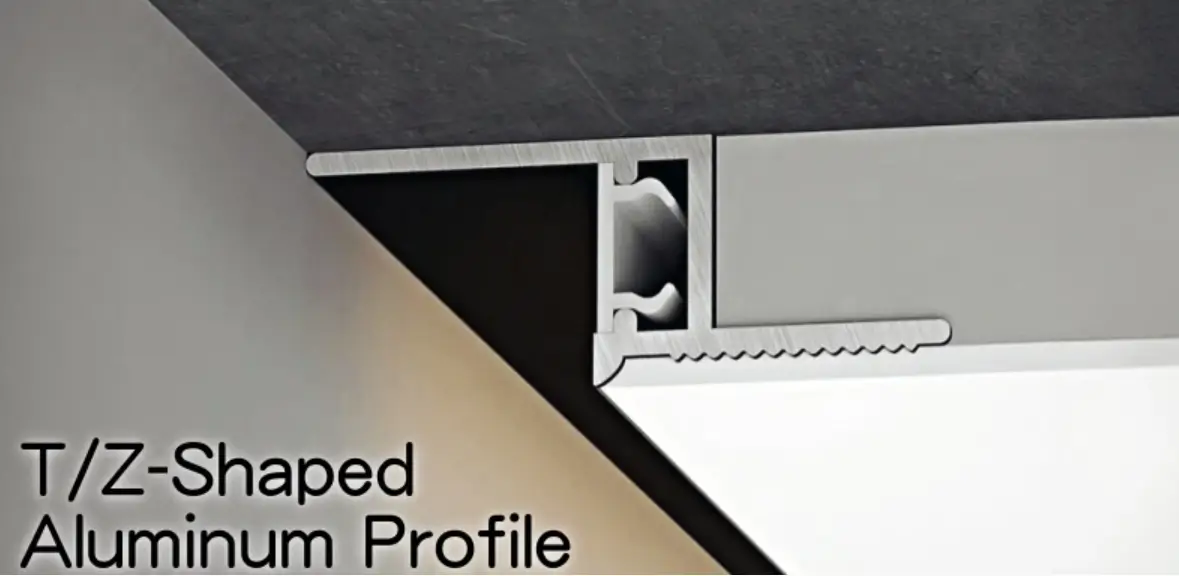

What is Z-Shaped LED Strip Metal Profiles

Z-shaped LED strip metal profiles are metal pieces shaped like a “Z.” They hold LED strip lights inside. The Z shape lets them fit on ceilings, walls, or corners, which is great for pretty lighting. These profiles do many things:

- Protection: They keep dust, water, and bumps away from LED strips.

- Heat Control: They act like heat sinks to keep LEDs cool and working longer.

- Better Look: They give a neat, clean finish, hide wires, and spread light evenly.

- Strong Support: They hold lights firmly in place.

Common materials are aluminum, which is light and good with heat, and galvanized steel, which is strong.

Applications of Z-Shaped LED Strip Metal Profiles

Z-shaped profiles work in many places:

- Ceiling Lights: They fit into hanging ceiling systems for soft or bright lighting in homes, offices, or shops.

- Wall Lights: They highlight walls or make cozy mood lighting.

- Under-Cabinet Lights: They go under kitchen cabinets or shelves for task lighting.

- Big Projects: They’re used in museums, galleries, or public spaces for creative designs.

- Outdoor Lights: With weather-proof materials, they work for building fronts or gardens.

Roll Forming Machines for LED Strip Metal Z-Shaped Profile

Overview of Roll Forming

Roll forming is a process where a metal strip goes through rollers to form a shape. For Z-shaped profiles, the metal bends little by little into a Z shape. This method makes long, same-shaped profiles fast, which is perfect for big projects.

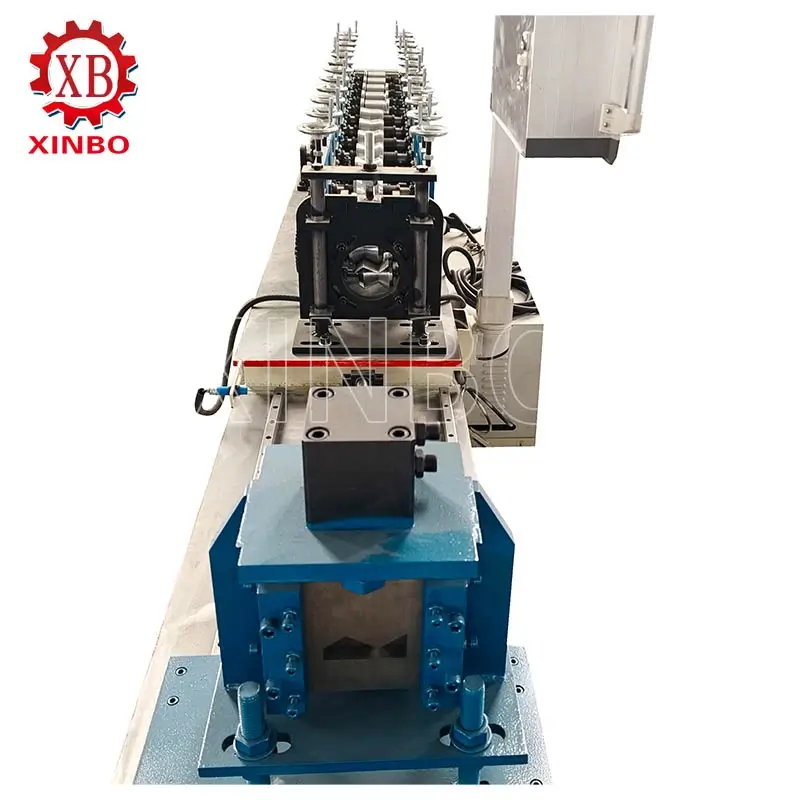

Key Components of Z-Shaped LED Strip Metal Profiles Roll Forming Machines

A typical machine has these parts:

- Çekici: It unwinds the metal coil and feeds it smoothly.

- Feeding and Guiding System: It keeps the metal strip straight for the rollers.

- Rulo Şekillendirme Bölümü: It has many rollers that shape the metal into a Z-profile step by step.

- Kesme Sistemi: It cuts the profile to the right length using hydraulic or mechanical tools.

- Kontrol Sistemi: It runs the machine, controlling speed and accuracy with programmable logic controllers (PLCs).

- Çıkış Tablosu: It collects the finished profiles for stacking or more work.

Process Flow of Z-Shaped LED Strip Metal Profiles Roll Forming Machines

Here’s how it works:

- Load Material: A metal coil, like galvanized steel or aluminum, goes onto the decoiler.

- Feed and Level: The strip moves through a system to make it flat.

- Rulo Şekillendirme: Rollers bend the strip bit by bit into a Z shape.

- Punch and Cut: Some machines add holes for mounting or air flow, then cut the profile to size.

- Çıkış: The finished profiles are stacked and ready.

Advantages of Z-Shaped LED Strip Metal Profiles Roll Forming Machines

- Fast Work: They make long profiles at 12-15 meters per minute or more.

- Para tasarrufu: They’re great for big batches, cutting down on labor and material costs.

- Many Materials: They handle steel, aluminum, or stainless steel.

- Flexible Sizes: Rollers adjust to make different profile sizes or shapes.

Limitations of Z-Shaped LED Strip Metal Profiles Roll Forming Machines

- Finish Quality: Surfaces might not be as smooth as with extrusion, which matters for nice-looking LED profiles.

- Complex Shapes: Adding features like diffusers is tough with roll forming.

- Custom Costs: Special rollers for unique Z-profiles can cost a lot.

Applications of Z-Shaped LED Strip Metal Profiles Roll Forming Machines

img.Z-Shaped LED Strip Metal Profiles.webp

When set up well, these machines:

- Fit perfectly into hanging ceilings.

- Make stylish wall lighting.

- Provide bright light under cabinets.

- Act as design pieces in galleries or hotels.

Roll forming works well when strong structures are needed.

Market Trends and Future Developments

The world wants energy-saving buildings, so demand is growing:

- More LED Lighting: People want energy-saving lights, so LED strip profiles are needed more.

- Özel Seçenekler: Manufacturers make machines that can be adjusted for special profiles.

- Eco-Friendly: Using recycled metals and efficient machines helps the environment.

- Smart Tech: Adding IoT and AI helps monitor machines in real time.

These changes show roll forming will keep improving for decorative LED uses.

Challenges and Considerations

Some things to think about:

- Profile Fit: Z-shaped profiles must match LED strip sizes (usually 8–12 mm).

- Careful Setup: Installation needs to be exact for safety.

- Cost Issues: Custom tools can be pricey.

- Market Limits: Machines just for LED profiles are rare, so you need to work closely with makers.

Z-shaped LED strip metal profile roll forming machines make special profiles for ceiling and wall lights.

Buy Z-Shaped LED Strip Metal Profile Roll Forming Machine from XinBo

XinBo'nun is a Chinese manufacturer since 2014. A team of skilled designers and workers ensures quality.

With over ten years in custom machines:

- Our factory has expert engineers and designers. They draw detailed plans fast to match customer needs exactly.

- We have our own workshop, CNC machines, and workers, which keeps costs low.

- Every machine gets checked three times before shipping to ensure good quality.

XinBo'nun adapts standard purlin-forming tech for decorative profiles, making them a great choice for reliable roll forming machines.

Sık Sorulan Sorular

Q1: Can XinBo customize machines for narrow-width LED strips?

A: Yes. Our skilled engineers design detailed plans, including for narrow LED strips.

Q2: What materials work with XinBo’s machines?

A: They handle aluminum, galvanized steel, and stainless steel, used for both purlins and lighting channels.

Q3: Are these machines only for big production?

A: They’re best for big batches, but ODM & OEM options work for medium-sized needs too.

Q4: How long to deliver a custom machine?

A: With our CNC machining, we deliver fast. Times vary by customization.

Q5: Is training provided after buying?

A: XinBo gives technical support after purchase. Bize ulaşın at serena@cnxinbo.net or +86 18931871722.

İlgili Yazılar

İyi kaliteli

XinBo makine yapma CO. LTD rulo şekillendirme makinesinde profesyonel bir üretici ve ihracatçıdır,

Daha Fazlasını Görüntüle→

İspanyolca

İspanyolca Rusya

Rusya