Best Rain Gutter Roll Forming Machine for Sale – Buyer’s Guide

What Is a Rain Gutter Roll Forming Machine?

Bir rain gutter roll forming machine is a carefully crafted tool that turns metal sheets, like aluminum, galvanized steel, or copper, into specific gutter shapes such as K-style, half-round, and box gutters. It works by steadily bending and pressing the metal to create gutters. These gutters help gather and guide rainwater away from buildings, keeping foundations and walls safe from water harm. Such machines are vital in today’s building projects because they work fast, can be tailored to needs, and make seamless gutters right at the work site.

Types of Rain Gutter Roll Forming Machines

Stationary Rain Gutter Roll Forming Machines

Stationary machines are meant for big production runs in factory settings. These tough systems handle large tasks, like making gutters for huge industrial or business buildings. They can work with thicker metals, up to 24-gauge steel, and use smart PLC systems for exact control with very little handwork needed.

Manual vs. Electric Rain Gutter Roll Forming Machines

Manual machines need human strength to run and are good for small jobs or places without much power. On the other hand, electric ones are much quicker thanks to motors and automatic features. Electric Machines: They save on labor costs and boost the amount of work done.

Key Features of High-Quality Rain Gutter Roll Forming Machines

Çekirdek Bileşenler

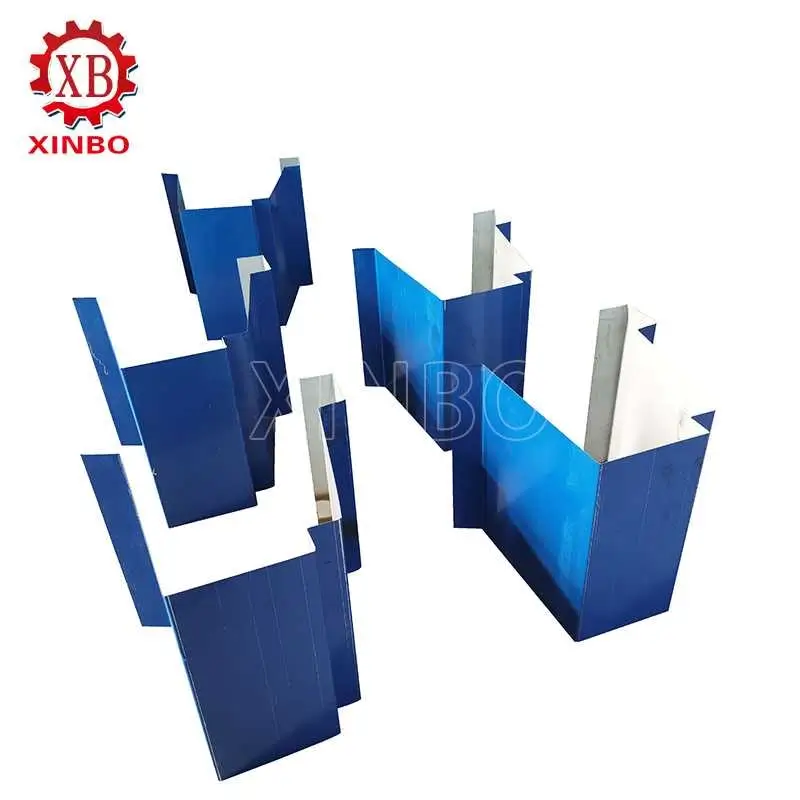

Decoiler: It sends metal coils into the machine, keeping the flow steady. Feeding and Leveling Device: This makes sure the metal sheet is straight and even before it goes into the roll forming part. The roll forming system uses strong forged steel rollers, coated with hard chrome (0.05mm), to shape the metal just right. Hydraulic Cutting Unit: It cuts with great care, staying within ±2mm of the target. A PLC Control System handles settings like length and number automatically. Run-Out Table: It holds the finished gutter as it comes out of the machine.

Teknik Özellikler

Top-notch machines can handle metals like aluminum, copper, PPGI (pre-painted galvanized iron), and galvanized steel, with thicknesses from 0.3mm to 0.5mm for portable ones, or up to 24-gauge for stationary types. Production Speed: It varies between 10 to 20 meters per minute. Power needs range from 5.5kW to 9kW based on the setup.

Ek Özellikler

Some models have polyurethane drive rollers that keep drive action separate from forming force, reducing strain on the material. Free-floating rollers make it easier to use different metals without constant tweaks. Safety guards and quick-stop buttons keep workers safe while using the machine.

Benefits of Using Rain Gutter Roll Forming Machines

Cost Savings: Making gutters at the site means you don’t need to buy ready-made ones, cutting down on expenses and waste. Tailoring lets you match gutter sizes perfectly to the building. Longevity: Seamless gutters don’t leak easily, giving steady performance and lowering repair costs. Automatic controls help get more done with less help needed.

Buyer’s Guide: How to Choose the Best Rain Gutter Roll Forming Machine

Assess Your Project Requirements

Figure out the usual gutter sizes you need—5-inch K-style for houses or bigger ones like 6-inch or box types for factories. Pick materials based on local weather; aluminum works well near the sea, while galvanized steel holds up better against bumps and knocks.

Evaluate Machine Features

Go for models with PLC systems for easy automatic work. Make sure rollers are made of chrome-plated forged steel for a long life. A hydraulic guillotine cutter gives smoother edges compared to hand-cutters.

Consider Regional Factors

Pick machines that can make larger gutter shapes if you’re in a rainy area. The metal thickness should fit the weather needs too; thicker metal might be better in places with lots of storms.

Verify Supplier Reliability

Choose sellers with ISO 9001 and CE marks to be sure of good quality and safety rules. Suppliers with big spaces (5,000+ m²) and many repeat buyers (40% or more) show they’re dependable. After-sales help should cover training, spare parts, warranties, and third-party checks if you ask for them.

Budget and Cost Considerations

Portable machines often cost less at first but might not make as much as stationary ones. Think about all running costs, like upkeep, power use, and savings from automatic features.

Maintenance and Storage

Regular Care: Clean and oil rollers often to stop any odd shapes from forming. Keep machines inside when not in use; don’t let them get wet as it can lead to rust or wiring issues.

Market Trends and Innovations in Rain Gutter Roll Forming Machines

Smart Tech and Automation: New machines come with high-end PLC systems and easy touchscreen controls. There’s also a growing need for green materials like recyclable aluminum. Makers are focusing on flexibility due to different building styles around the world. Global Supply Chains: Companies in places like China lead with low prices and huge production setups.

Challenges and Considerations

Learning to use these machines can be tough at first, especially when switching from handwork to automatic systems. Material costs can change a lot—copper is often pricey—and steady upkeep is needed to avoid alignment problems that hurt the final product.

Tips for Maximizing ROI on Rain Gutter Roll Forming Machines

Focus on Training: Teach workers well to cut down on mistakes and get the most out of the machine. Combo machines that make various shapes give more options for different jobs. Try to get longer warranties from the start if you can. Add tools like digital controllers or run-out tables to improve work output.

Sık Sorulan Sorular

Q1: What profile types can these machines produce?

Most machines handle K-style (5\, 6\, combo), half-rounds, and box shapes based on their setup.

Q2: Can I use different materials?

Yes—aluminum, copper, PPGI-coated steel sheets all work within the thickness limits for each model.

Q3: Are portable units durable enough?

Yes—they’re built with strong parts but made for easy moving rather than huge production amounts.

Q4: How much does it cost per foot of gutter produced?

Making 100 feet of aluminum gutters costs around $400–$800, not counting setup fees.

Q5: Is technical support available internationally?

Trustworthy suppliers provide worldwide after-sales help, including fixing issues from afar.

Get the Best Rain Gutter Roll Forming Machine for Sale from XinBo

XinBo'nun machine making company is a full-on manufacturer started in 2014. We promise top-quality machines and fresh ideas, thanks to our skilled engineers, techs, and workers. Our roll forming machines are shaped and built to match what customers want. With sales reaching from Europe to Africa—places like Poland, UAE, USA—their name stands on CE-certified goods with full service from design to setup. “Dedicated, united, innovative, mutual benefit” is our guiding idea. Bize ulaşın now—XinBo replies within 24 hours!

İlgili Yazılar

İyi kaliteli

XinBo makine yapma CO. LTD rulo şekillendirme makinesinde profesyonel bir üretici ve ihracatçıdır,

Daha Fazlasını Görüntüle→

İspanyolca

İspanyolca Rusya

Rusya