Considerations for Choosing the Right Metal Wall Panel Roll Forming Machine

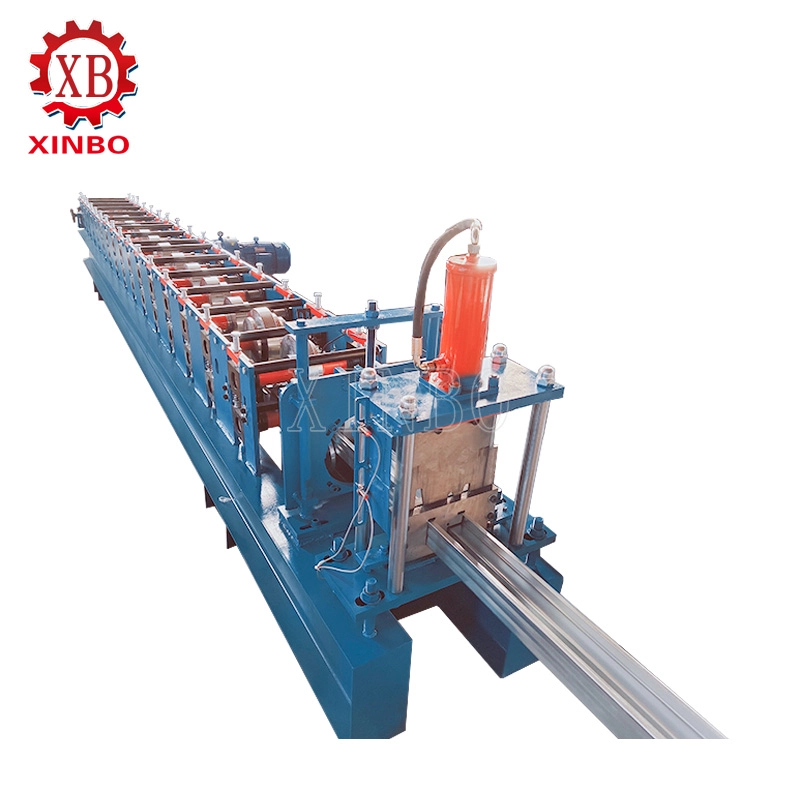

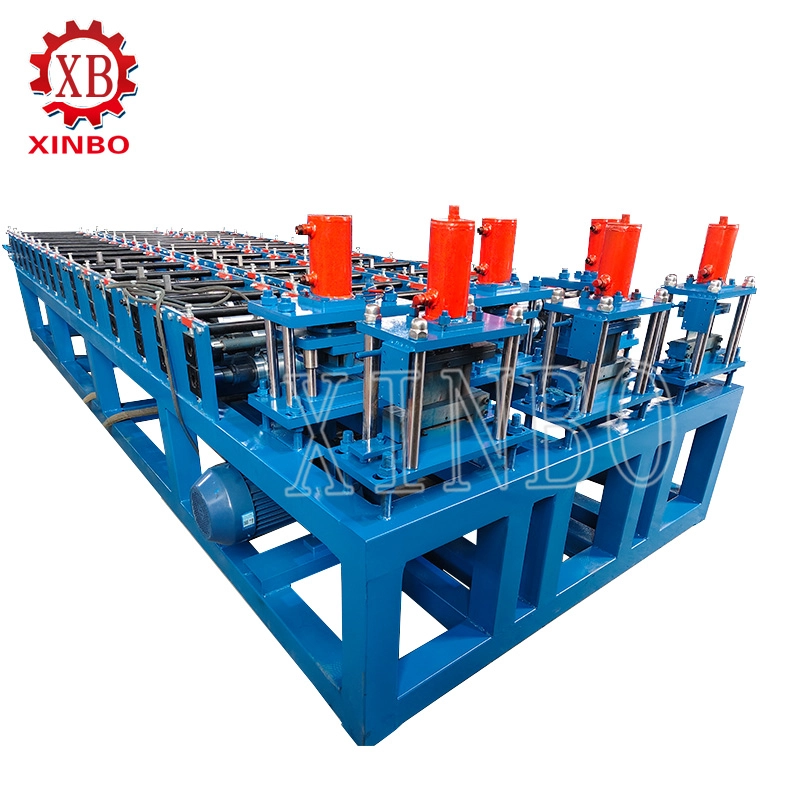

Metal wall panels find wide use in today’s buildings, advertising decoration systems, ceilings, and exterior wall cladding. Their neat look, solid structure, and strong resistance to weather make them a top choice for business buildings, factory sites, and branded building facades. Behind each good-quality panel stands a dependable metal wall panel roll forming machine. This equipment creates steady profiles, exact sizes, and fast output.

This piece looks into the main factors for picking the correct metal wall panel roll forming machine. It focuses on performance, design details, flexibility in production, and lasting dependability. Whether the use involves metal facade decoration, ceiling panels, or exterior wall systems, knowing the machine well matters a lot before deciding.

Understanding the Role of a Metal Facade Panel Wall Panel Roll Forming Machine

A metal facade panel wall panel rulo şekillendirme makinesi gets built to shape flat metal coils into decorative and useful wall panels in a steady process. It uses a series of accurate rollers. These machines often serve for advertising panels, building cladding, hanging ceilings, and outside wall covers. Here, surface quality and size precision prove very important.

How Roll Forming Supports Decorative and Structural Requirements

In advertising decoration and building facade work, panels need to satisfy both beauty and practical needs. Roll forming methods allow smooth and repeated panel shapes. They provide steady rib height and spacing for even looks. They offer tight limits good for modular setup. And they work well with surface finishes like painting or coating.

A properly built machine makes sure every panel from the line keeps the same look and fit. This proves key for big facade or ceiling projects.

Production Stability in a Metal Wall Panel Roll Forming Machine

When checking a metal wall panel roll forming machine, production stability ranks as one of the top technical aspects. Stability directly impacts panel flatness, edge precision, and ongoing output efficiency.

Key Engineering Factors That Influence Stability

-

Roller material and machining accuracy High-precision rollers cut down vibration and surface flaws during forming.

-

Machine frame rigidity A strong welded frame limits bending under steady load, especially in long runs.

-

Drive system coordination Good matching between motors, gearboxes, and shafts keeps material feeding and forming smooth.

Stable machines lower waste rates. They also help keep steady panel quality for exterior wall and ceiling uses where setup limits stay strict.

Precision Requirements for a Metal Siding Wall Panel Roll Forming Machine

A metal siding wall panel roll forming machine must produce panels that line up perfectly during setup. This holds true especially for exterior walls and advertising facades open to public sight.

Why Dimensional Accuracy Matters

In actual projects, even small differences can lead to misalignment during panel setup. They may cause gaps that hurt weather resistance. Or they create uneven looks across large wall areas.

Precise forming helps make sure siding panels lock or line up as planned. This improves both appearance and function. It matters greatly for metal wall panels in outdoor advertising structures and building exteriors.

Engineering Capabilities of a Custom Metal Wall Panel Machine

Many building and advertising projects need panels with special profiles or sizes. In those situations, a custom metal wall panel machine offers a useful answer.

When Customization Is Necessary

Customization may prove needed for non-standard panel widths or rib patterns. It helps with decorative surface designs for branded facades. Or for ceiling panels with certain load or hanging needs. And for exterior wall systems built to include insulation or lighting.

A machine designed with customization in view lets makers respond quickly to project needs. They do so without hurting output efficiency.

Automation and Control Systems in Modern Metal Wall Panel Machines

Automation plays a big part in raising consistency and cutting reliance on workers. Advanced control systems now come as common features in top-quality equipment from skilled metal wall panel machine manufacturers.

Benefits of Intelligent Control Systems

-

Accurate length cutting for each panel

-

Simple changes for different panel specs

-

Less setup time between production runs

-

Better safety and work reliability

For firms making panels for advertising decoration, ceilings, and exterior walls, automation aids in keeping quality. It also supports growth in production.

What to Expect from a Reliable Metal Wall Panel Machine Manufacturer

Picking the right equipment ties closely to choosing a trustworthy metal wall panel machine manufacturer. Technical knowledge, design skills, and ongoing service support all affect machine performance over its life.

Characteristics of Established Manufacturers

-

Deep knowledge of roll forming technology

-

Ability to give technical advice based on application needs

-

Steady manufacturing standards

-

Strong after-sales support and spare parts supply

Professional metal wall panel machine manufacturers focus not just on building machines. They also help customers reach stable and efficient production.

Evaluating Expertise Among Metal Wall Panel Machine Companies

Not all metal wall panel machine companies provide the same level of technical strength. When comparing choices, look past basic specs.

Key Evaluation Points

-

Engineering team experience with facade, ceiling, and exterior wall panels

-

Knowledge of material behavior during forming

-

Ability to improve forming steps for decorative panel uses

-

Proven history in supplying industrial-grade machines

A strong metal wall panel machine company can turn building and decorative needs into solid mechanical answers.

Long-Term Value from the Right Metal Wall Panel Machine Company

A wisely picked metal wall panel machine company supports customers past the first delivery. Long-term value comes from machine strength, upgrade options, and technical help.

For makers producing metal panels used in advertising displays, ceilings, and exterior walls, machine uptime and consistency directly affect business results.

Key Considerations for Choosing the Right Metal Wall Panel Machine

When reaching a final choice, these considerations for choosing the right metal wall panel machine deserve careful review:

-

Structural strength and forming accuracy

-

Compatibility with intended panel applications

-

Customization capability for decorative and architectural designs

-

Automation level and ease of operation

-

Technical support and manufacturing expertise

A balanced review makes sure the chosen machine meets current production needs. It also handles future project demands.

Frequently Asked Questions (FAQ)

What materials can a metal wall panel roll forming machine process?

These machines commonly handle coated steel, galvanized steel, and other metal coils suitable for decorative wall panels, ceilings, and exterior wall applications.

Is a custom metal wall panel machine necessary for advertising panels?

For unique visual designs or branded facade requirements, a custom solution helps achieve precise profiles and consistent appearance.

How does machine stability affect panel quality?

Stable forming reduces deformation, improves surface finish, and ensures uniform dimensions across all panels.

Can one machine support both ceiling and exterior wall panel production?

With proper design considerations, a single machine can be configured to meet multiple architectural panel applications.

Partner with XINBO for Reliable Metal Wall Panel Solutions

Engineering Expertise You Can Trust

XINBO'nun is a professional manufacturer specializing in roll forming machinery for metal wall panels used in advertising decoration, ceilings, and exterior wall systems. With strong engineering capabilities, a dedicated technical team, and comprehensive manufacturing experience, XINBO focuses on delivering stable, precise, and application-oriented solutions.

XINBO Business Scope: Design, manufacturing, and service of metal wall panel roll forming machines

Core Strengths: Custom engineering, production stability, technical support, and long-term reliability

If you are planning to invest in a metal wall panel roll forming solution or want expert guidance tailored to your application needs, XINBO is ready to support your project with professional insight and dependable machinery.Contact XINBO today!

İlgili Yazılar

İyi kaliteli

XinBo makine yapma CO. LTD rulo şekillendirme makinesinde profesyonel bir üretici ve ihracatçıdır,

Daha Fazlasını Görüntüle→

İspanyolca

İspanyolca Rusya

Rusya