Door Frame Roll Forming Machine for Sale: What Buyers Should Know

In today’s construction and metal work, the door frame roll forming machine serves as a key technology. It allows accurate and large-scale production of steel door frames. These machines turn flat metal coils into detailed shapes. Those shapes include rebates, hinge supports, lock openings, and strong edges. Such parts are essential for secure doors, fire-safe structures, office entrances, and modular buildings. Around the world, more people want strong, rust-proof options instead of old materials. Advanced steel door frame roll forming machine solutions from China provide very consistent results, save material, and fit well with other systems.

Serious buyers often look for a door frame roll forming machine for sale to improve their production setup. Many choose trusted door frame roll forming machine manufacturers and door frame roll forming machine supplier networks in China. They offer dependable and custom-made equipment. This detailed guide covers main technical points, how the process works, important performance numbers, and actual uses. It helps buyers choose wisely when looking for a metal door frame roll forming machine or china door frame roll forming machine.

Core Operating Principles of Door Frame Roll Forming Technology

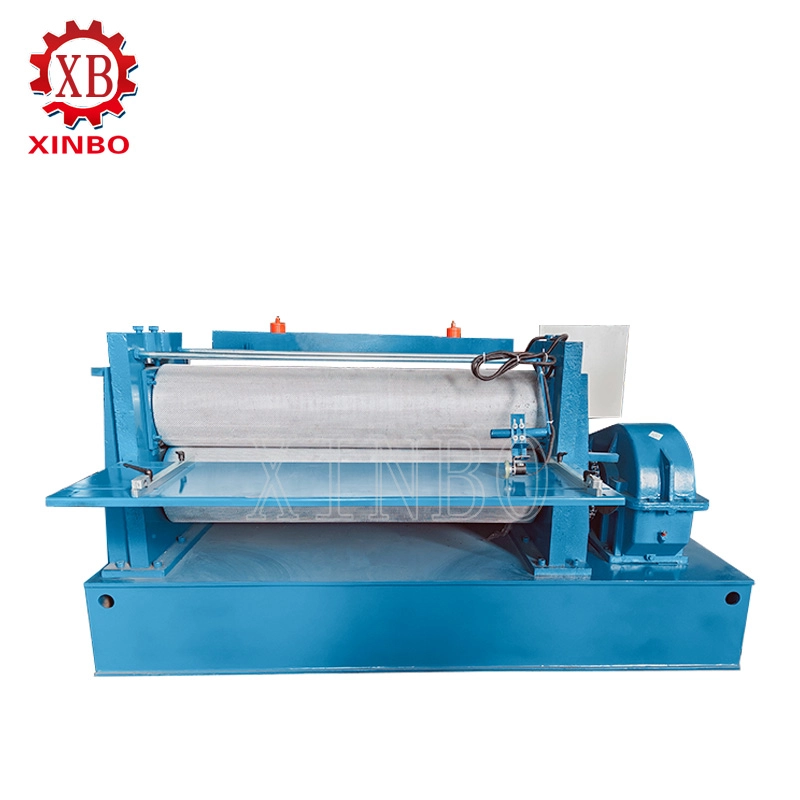

The door frame roll forming machine uses cold step-by-step forming. A long metal strip passes through many roller stations one after another. Each station puts steady pressure to bend the material little by little. In this way, it reaches the needed shape without much thinning or extra stress on the metal.

The usual production steps include:

-

Coil Uncoiling and Initial Alignment — Hydraulic or electric decoilers keep even tension. Servo guides make sure the strip enters straight and accurately.

-

Leveling and Pre-Processing — Multi-roller straighteners (5–9 rolls) remove coil bends and leftover stresses.

-

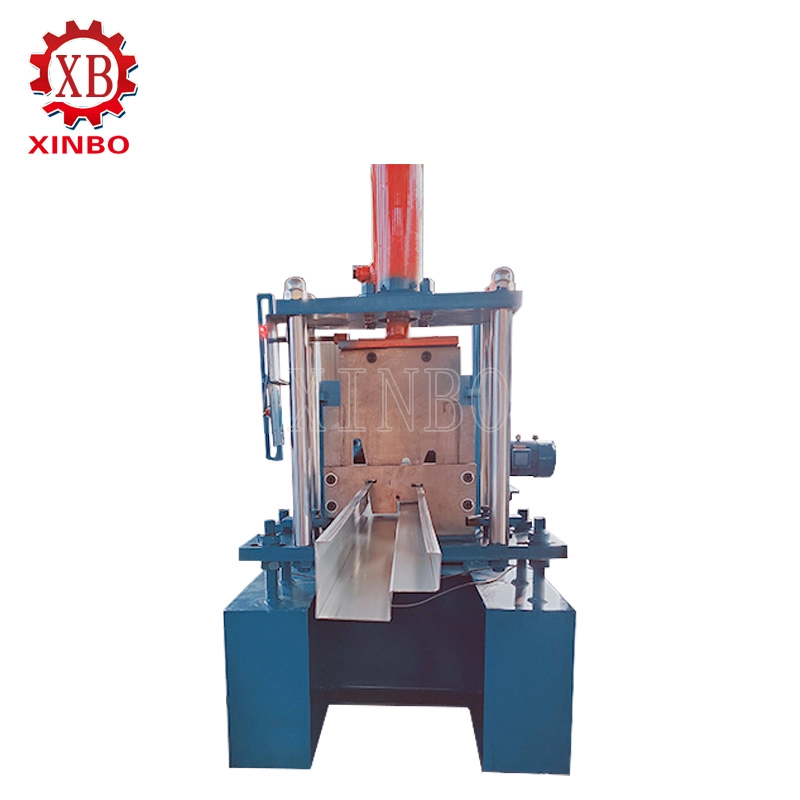

Inline Hydraulic Punching/Notching — Servo-controlled or fixed-die units make hinge slots, lock openings, reinforcement holes, and angled cuts at set spots.

-

Progressive Roll Forming — 14–22+ stations form the shape with carefully ground rollers. They create single-rebate, double-rebate, wrap-around, or multi-fold styles.

-

Post-Form Straightening and Calibration — Final rollers fix springback and keep dimensions steady.

-

Non-Stop or Flying Hydraulic Cutting — Servo-matched shears give clean, smooth cuts. Length accuracy reaches ±0.5–1 mm.

This steady process runs at 15–30 m/min. It keeps the surface smooth and the shape exact, which matters a lot for later assembly and fire safety approval.

Advanced Technical Specifications and Engineering Features

High-quality china door frame roll forming machine models come from specialized door frame roll forming machine factory operations. They include these strong features:

-

Roller Design and Material — Stations use GCr15, Cr12MoV, or SKD11 tool steel rollers. These are hardened to HRC 58–62 and coated with chrome (0.05–0.08 mm thick). That gives good wear resistance and shiny surfaces. Shafts usually measure 70–90 mm to reduce bending under weight.

-

Drive and Transmission Systems — Gearbox (ZQ series reducers) or universal joint setups deliver power evenly. Main motors of 7.5–15 kW handle thick material without slipping.

-

Punching and Notching Precision — Hydraulic units (10–16 MPa) with Cr12MoV blades allow punching at many positions. This works for left/right-hand frames, extra plates, or wire paths. Modern servo setups let patterns change during the coil run.

-

Control and Automation Architecture — Mitsubishi/Panasonic/Siemens PLC with 10-inch touchscreen HMI holds recipes, adjusts length by encoder, shows faults, and connects to Industry 4.0 for data records and remote checks.

-

Frame Construction — Stress-relieved welded H-beam or cast steel bases have precise mounting areas. They cut down vibration and keep alignment over time.

-

Material Handling Capability — Works with galvanized steel, cold-rolled steel, pre-painted coils, and high-strength low-alloy types; thickness from 0.6–2.5 mm; yield strengths up to 345–550 MPa.

These features support steady output of tricky shapes. They also meet global standards (e.g., EN 10152, ASTM A653).

Key Performance Parameters to Evaluate

When checking a door frame channel roll forming machine or similar from a good door frame roll forming machine manufacturers source, focus on these points:

-

Forming accuracy (±0.3–0.8 mm on key sizes)

-

Repeatability from shift to shift

-

Surface quality (Ra <0.8 μm usual after forming)

-

Changeover efficiency (cassette or quick-roll setups cut downtime to <45 minutes)

-

Energy use and hydraulic system dependability

Top models add servo feeding for precise spacing control and flying shear for nonstop fast work.

Primary Applications in Modern Construction and Fabrication

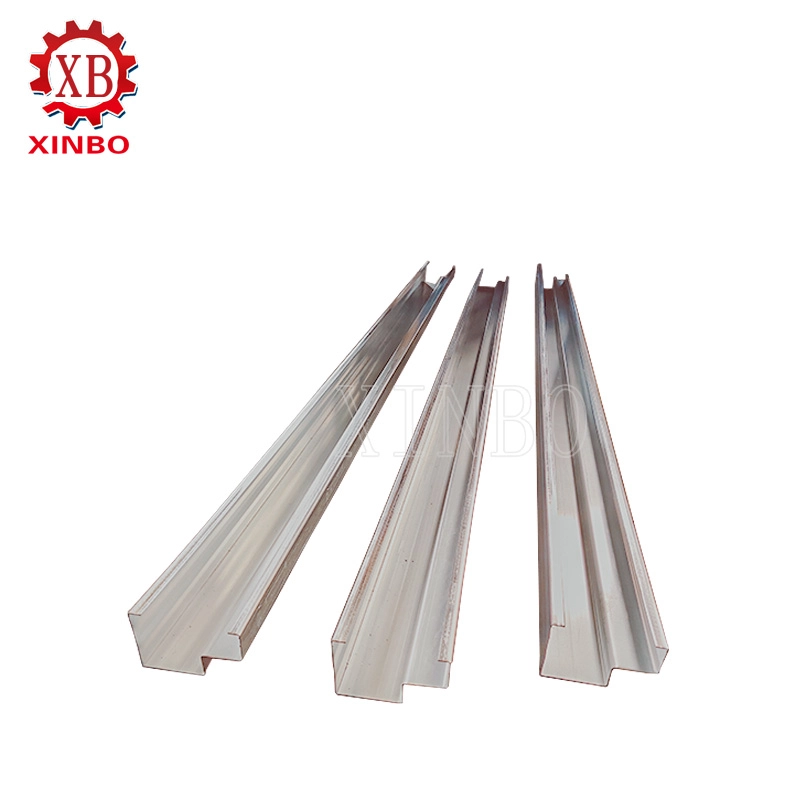

Door frame roll forming machine products fit many areas where strength, fire safety, and quick setup matter most:

-

Residential and Multi-Family Housing — Standard single/double-rebate frames for inside and outside doors. They give rust protection and simple updates.

-

Commercial and Institutional Buildings — Strong profiles for offices, hospitals, schools. They support busy hardware and sound seals.

-

Fire-Rated and Security Door Assemblies — Reinforced parts meet UL, BS, or GB fire rules. They include intumescent channels and anti-force features.

-

Industrial and Modular Construction — Solid frames for warehouses, factories, cleanrooms, and prefab units. Fast on-site work lowers labor costs.

-

Specialized Applications — Shapes for sliding doors, folding walls, elevator openings, and blast-proof systems in secure places.

This method makes light but stiff parts. They beat wood in size stability, termite protection, and long life—especially useful in wet or seaside areas.

Strategic Considerations for Technical Buyers

Look for machines with flexible add-ons (e.g., extra punching units), strong support documents after sale, and fit with later automated steps like robot welding or powder coating. Check supplier skills with shape samples, FEA stress reports, and real factory setups. Many buyers want oem door frame roll forming machine setups for special or branded shapes. China door frame roll forming machine factory suppliers often do well at custom OEM work.

أسئلة متكررة

What profile complexities can modern door frame roll forming machines handle?

Advanced systems make single-rebate, double-rebate, wrap-around, reinforced, and uneven shapes with built-in edges, holes, and multi-bend parts.

How precise is inline punching for hardware preparation?

Servo-driven punching reaches ±0.5 mm position accuracy. It handles different hinge/lock layouts and handed setups on one coil.

What production volumes justify investment in a high-automation door frame roll forming machine?

Lines at 15–30 m/min fit factories making 500–3000+ frames per shift. Semi-automatic ones work for 100–800 units daily.

Can these machines accommodate varying material strengths and coatings?

Yes—designs manage galvanized, pre-painted, and high-tensile steels up to 550 MPa. Roller shapes prevent cracks or coating harm.

What integration options exist for larger production ecosystems?

Many allow coil-fed automation, MES links, and output conveyors for smooth moves to assembly, welding, or painting areas.

Elevate Your Production Capabilities with Advanced Door Frame Roll Forming Technology

Picking the correct door frame roll forming machine affects product quality, daily work flow, and future strength in tough construction fields. شينبو, started in 2014 in China, specializes in custom cold roll forming solutions. It supplies machines made to match exact profile needs with focus on accurate build, automation fit, and worldwide standards.

Their engineering team offers full shape review, simulation help, and on-site setup to reach top results right away. For expert advice on a steel door frame roll forming machine, metal door frame roll forming machine, oem door frame roll forming machine, or fully custom china door frame roll forming machine setup from a dedicated china door frame roll forming machine factory, contact XINBO at serena@cnxinbo.net. Talk about your technical needs and see how XINBO’s skills can improve your production line.

مشاركات ذات صلة

الإسبانية

الإسبانية روسيا

روسيا