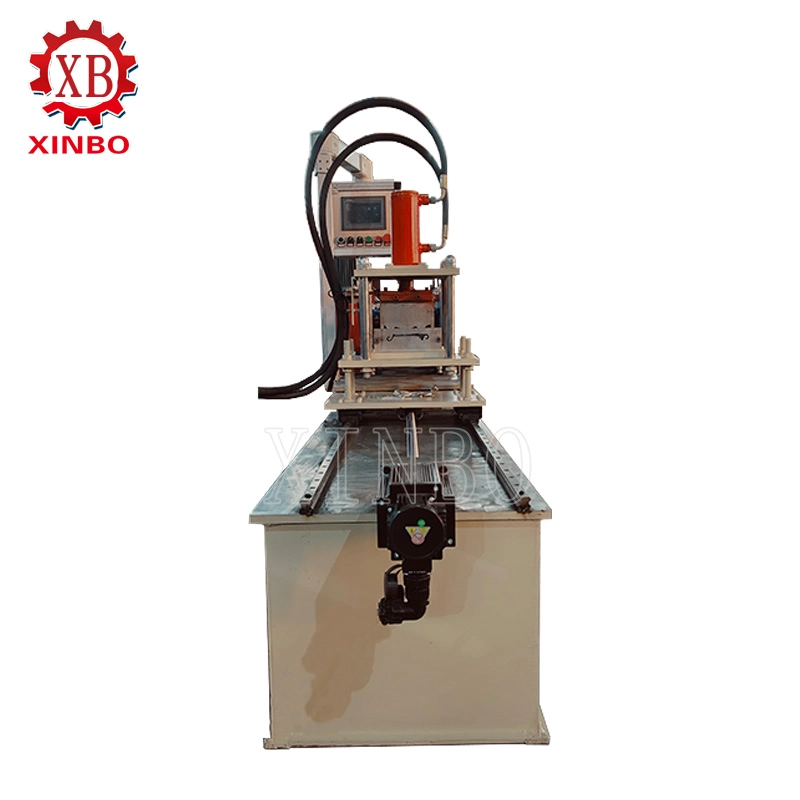

Shutter Door Frame Cold Roll Forming Machine Bulk Buy Guide

In today’s quick-moving manufacturing world, the shutter door frame cold roll forming machine has turned into a key tool. Producers use it to get excellent precision and good efficiency when they make top-quality roller shutter parts. No matter if production grows for commercial garages, industrial warehouses, or home security doors, knowing the details of a dependable roller shutter door roll forming machine can really affect the quality of output and running costs. This full guide looks closely at the technology, main features, and smart ways to buy these machines in large amounts. It helps buyers choose wisely in a tough market.

Understanding the Shutter Door Frame Cold Roll Forming Machine: Core Principles and Operation

The shutter door frame cold roll forming machine works based on the basic idea of cold roll forming. This is a steady bending method. It changes flat metal strips into exact profiles without any heat on the material. The way works well to keep the structure strong. At the same time, it gives very good size accuracy.

At its core, an automatic shutter door roll forming machine begins with a coil. The coil is usually galvanized steel, pre-painted steel, or aluminum. It is often 0.3–1.2 mm thick and up to 300 mm wide. The material goes through a decoiler first. Then a leveling system straightens it. After that, a line of hardened roller stations shapes it step by step—most times 18 to 28 stations, based on how complex the profile is.

How the Roll Forming Process Delivers Unmatched Precision

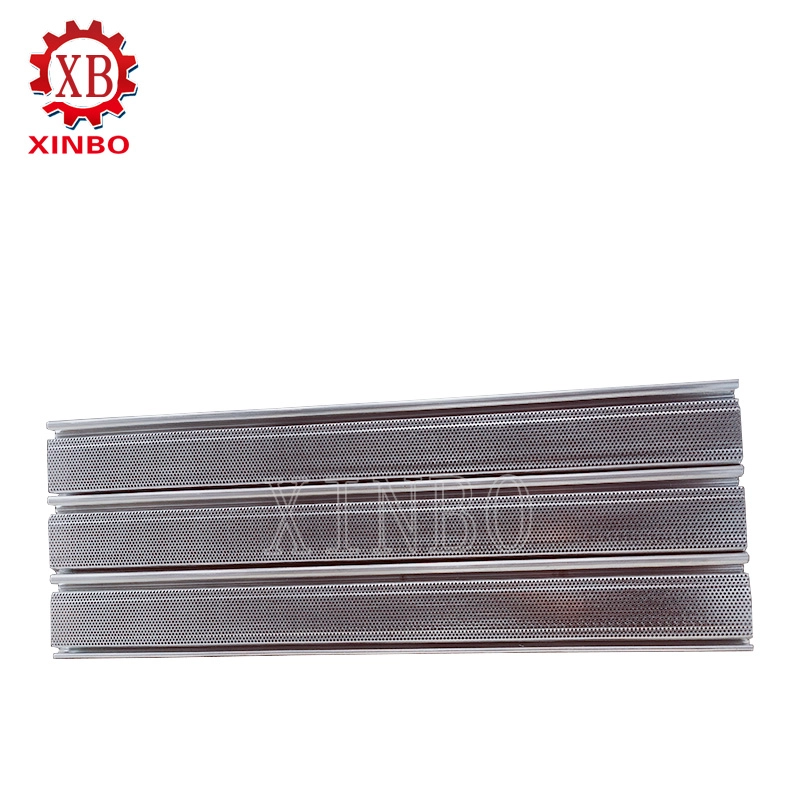

The best roll shutter door forming machine stands out because of its step-by-step forming method. Each roller station puts on a small and planned bend. It slowly shapes the metal into the needed shutter slat or frame profile. This step-by-step way cuts down stress on the material. It also lowers spring-back problems. As a result, it reaches tight tolerances like ±0.2 mm. That is much better than old pressing ways.

Modern China shutter door roll forming machine designs use Cr12MoV or SKD11 steel rollers. These have hard chrome plating (0.05 mm thick) and careful grinding. So they last long and give steady results even after many millions of cycles. The outcome is clear. Shutter door frames come with perfect locking edges, even surfaces, and no waves at all. These points matter a lot for smooth door work and good protection from weather.

Key Components of a High-Performance Shutter Door Frame Cold Roll Forming Machine

A high-level roller shutter door roll forming machine is a smart mix of connected systems. They all work together well. Here is a simple list of main parts that help its good performance.

Decoiler ونظام التغذية

The work starts with a hydraulic or manual decoiler. It can handle 3–8 ton coils. Better versions have automatic tension control and edge guides. These stop the material from going off track. So the strip enters the forming part smoothly.

Leveling and Punching Units

Nine-roller leveling tools flatten the strip. Optional servo punching systems make holes for locks, handles, or air flow. They do this with high accuracy at speeds up to 35 m/min.

Main Roll Forming Section

This is the main part in an OEM door shutter roll forming machine. Precision-cut shafts (usually 60–80 mm wide) hold roller dies. The dies come from good alloy steel. Heat treatment brings them to 58–62 HRC. CNC work makes sure rollers are exact. That lets the machine handle hard profiles such as curved slats or strong frames.

Hydraulic Cutting and Control Systems

After forming, a flying hydraulic cut (not stop-start type) keeps production going without losing speed. A Mitsubishi or Siemens PLC with touchscreen HMI controls everything. It lets users set lengths, count batches, and see faults right away.

The Top Features of a Roller Shutter Door Machine Explained

When checking machines for bulk buy, pay attention to features that bring real returns.

Unmatched Precision and Efficiency: Servo motor drives and encoder signals keep length exact within 1 mm over 10 meters. High-speed lines hit 25–60 m/min. That triples output over old machines.

تنوع المواد: It works with galvanized steel, stainless steel, aluminum, and pre-painted coils. Surfaces stay safe because of polyurethane-coated support rollers.

Automation Level: Fully automatic shutter door roll forming machine types have auto-stacking tables. This cuts labor by 70% and lowers damage from handling.

Durability Enhancements: Strong welded frames get stress-relief work. Imported seals go in hydraulic parts. So they give 10–15 years of solid work even with heavy use.

Safety and Energy Efficiency: Closed forming zones, emergency stops, and frequency inverters save power. They also follow CE and ISO rules.

Advantages of Investing in a Premium Shutter Door Frame Cold Roll Forming Machine

Moving to advanced shutter door frame cold roll forming machine bulkbuy brings big changes for the better.

First, production gets much faster. One line can make 5,000–10,000 meters of shutter profiles each day. Waste stays very low (under 1%) thanks to exact material use.

Second, product quality goes way up. Even wall thickness and perfect shape stop usual problems like door sticking or water getting in.

Third, custom work turns easy. Quick-change cassette setups let users switch shutter slat types in less than 30 minutes. This suits OEM makers who serve many markets.

Finally, costs drop a lot over time. Less repair work, smaller scrap amounts, and longer tool life all help.

How to Select the Right Shutter Door Frame Cold Roll Forming Machine for Bulk Purchase

Buying in bulk needs careful checks.

Assess production needs: Calculate required speed, profile complexity, and material types.

Verify technical specifications: Look for shaft diameter ≥ 70 mm, roller material hardness > 58 HRC, and PLC brand reputation.

Check after-sales support: Prioritize manufacturers offering remote diagnostics, spare parts inventory, and on-site training.

Demand samples: Test actual shutter profiles for fit, finish, and mechanical properties.

Consider expansion potential: Opt for modular designs that allow future upgrades like PU foaming integration or double-layer forming.

Maintenance Tips to Maximize Your Roller Shutter Door Roll Forming Machine Lifespan

Good care helps the machine last many years at top level.

Daily: Clean rollers and lubricate chains.

Weekly: Check hydraulic oil levels and alignment.

Monthly: Inspect roller wear and calibrate encoders.

Annually: Professional servicing of PLC and hydraulic systems.

These steps keep your China shutter door roll forming machine working well with very little stop time.

FAQ About Shutter Door Frame Cold Roll Forming Machine

Q: What materials work best with a shutter door frame cold roll forming machine?

A: Galvanized steel (G300–G550), pre-painted steel, aluminum (0.4–1.0 mm), and stainless steel are ideal for durability and corrosion resistance.

Q: How fast can an automatic shutter door roll forming machine produce?

A: High-end models achieve 25–60 meters per minute, depending on profile complexity and punching requirements.

Q: Is customization possible for specific shutter profiles?

A: Absolutely—professional OEM door shutter roll forming machines support fully custom roller designs based on your drawings.

Q: What makes the best roll shutter door forming machine stand out?

A: Combination of servo precision, heavy-duty construction, imported components, and flying cutoff for non-stop production.

Q: Can these machines integrate PU foaming for insulated shutters?

A: Yes, many advanced lines include inline foaming units for energy-efficient, noise-reducing shutter slats.

Q: What’s the typical power requirement?

A: 11–22 kW main motor plus 7.5–15 kW hydraulic station, operating on 380 V/50 Hz/3 Phase (customizable).

Ready to Upgrade Your Production with Professional Shutter Door Frame Cold Roll Forming Machine?

شينبو, established in China since 2014, is a 100% direct manufacturer specializing in high-precision roll forming solutions with over 10 years of expertise. Our team of professional engineers provides complete OEM/ODM services, custom machine design, rigorous three-stage quality inspection, and full after-sales support including installation guidance and technical training. All equipment meets international IEC standards and carries CE, UL, TUV certifications.

Contact XINBO today for expert consultation on your shutter door frame cold roll forming machine bulk buy needs. Let’s build your high-efficiency production line together—email us now or visit our factory to see unmatched precision in action!

مشاركات ذات صلة

الإسبانية

الإسبانية روسيا

روسيا