How a Retractable Pull-up Banner Aluminum Stand Roll Forming Machine Works

Retractable pull-up banner stands are key players in modern advertising. They shine at trade shows, conferences, retail spots, and promotional events. These portable displays are loved for their easy setup, sturdy build, and knack for showing off branding. Aluminum profiles give them strength and a sleek look. A special machine, the Retractable Pull-up Banner Aluminum Stand Rollo que forma la máquina, makes these profiles.

What is a Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

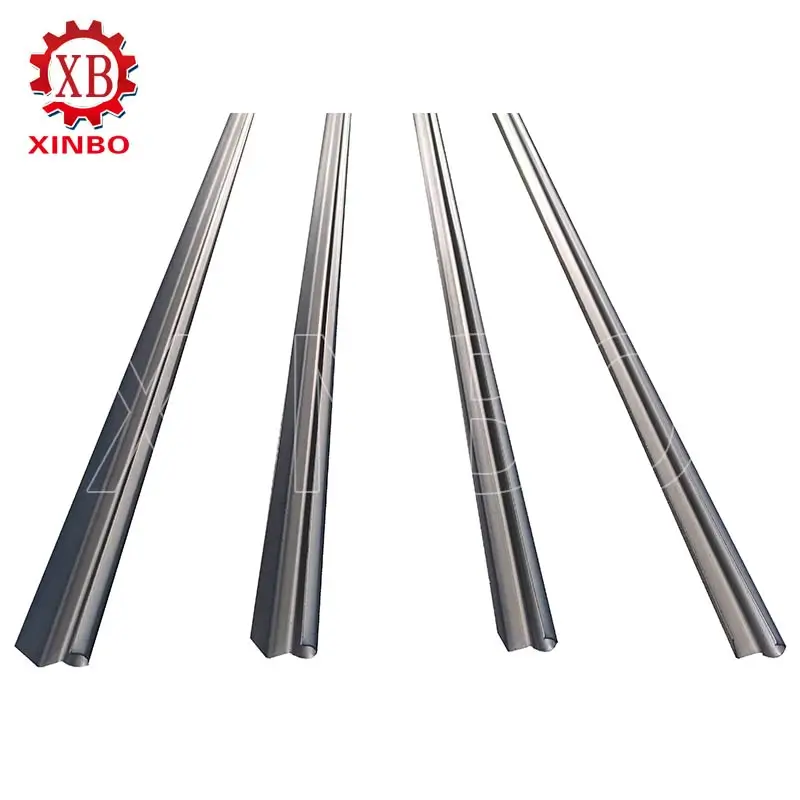

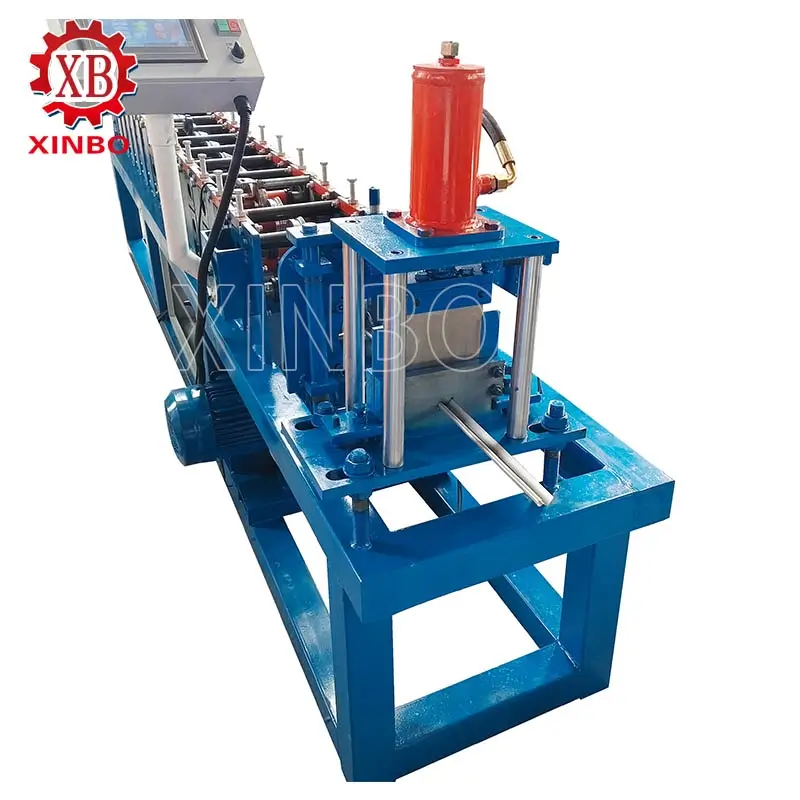

This machine is a heavy-duty tool built to craft aluminum profiles for retractable pull-up banner stands. These profiles are long, light, and shaped into forms like U or C channels, which are vital for the stands’ structure. The machine uses roll forming, a process where a flat aluminum sheet passes through pairs of rollers. Each pair bends the metal a bit, slowly shaping it into the needed profile.

Roll forming is fast and wastes little material, making it great for mass production. The aluminum profiles form the base, pole, and other parts of banner stands. They’re light yet tough enough to hold printed graphics.

Working Principle of Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

The machine works through roll forming with these main steps:

Alimentación de materiales

A coil of aluminum sheet sits on an uncoiler. The uncoiler feeds the sheet into the machine at a steady pace. This ensures a smooth flow of material.

Rollo de formación

The sheet moves through a series of roll stations. Each station has rollers that press and bend the aluminum a little. More complex shapes need more stations.

Progressive Bending

Each roller pair adds a small bend. This gentle process avoids cracking or over-stretching the aluminum, which can harden under stress.

Corte

Once the sheet is shaped into the profile, a cutting tool, like a flying shear or rotary cutter, slices it to the right length. This makes pieces ready for banner stand assembly.

Colección

The cut profiles land on a conveyor or stacking system. They’re ready for more processing or direct use in stands.

This nonstop process churns out long profiles with steady quality and size, perfect for banner stands.

Top Features of Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

These machines come with cool features to boost their work:

-

Versatilidad del material: They handle aluminum sheets from 0.5mm to 3mm thick. Common alloys like 6061 and 6063 are used for their bendy nature and rust resistance.

-

Profile Complexity: They make simple or tricky shapes, like profiles with flanges or ribs, adding strength to banner stands.

-

Alta velocidad: Roll forming is super quick, hitting speeds over 100 feet per minute, based on the machine and profile.

-

Precisión: Carefully made rollers ensure every profile is identical, with tight specs for smooth assembly.

-

Automation: Many machines have auto systems for feeding, cutting, and stacking, cutting labor costs and boosting speed.

-

Customization: Machines can be tweaked to make different profile shapes for various banner stand designs.

-

Durabilidad: Built from tough stuff like steel or cast iron, they handle nonstop work.

Machine Components of Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

The machine has key parts, each doing an important job:

-

Desbobinador: Holds the aluminum coil and feeds it steadily, keeping tension even.

-

Roll Stations: The heart of the machine, where rollers shape the metal. Each station bends a specific part of the profile.

-

Drive System: Powers the rollers and moves the sheet through. It’s strong to handle constant bending forces.

-

Sistema de corte: Slices the formed profile to exact lengths with tools like flying shears or rotary cutters.

-

Sistema de control: Uses computer controls to manage speed, roller pressure, and cutting timing for spot-on profiles.

-

Características de seguridad: Has emergency stops, guards, and interlocks to keep operators safe from heavy machinery and sharp metal.

-

Auxiliary Equipment: Includes lubricators to ease roller friction, stackers for profiles, and conveyors for moving them along.

Applications of Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

The main job is making aluminum profiles for retractable pull-up banner stands. But roll forming’s flexibility allows other uses:

-

Other Display Systems: Profiles work in trade show booths, exhibition stands, and retail displays needing light, strong structures.

-

Signage: Used in channel letters, light boxes, and illuminated signs for support and mounting.

-

Furniture and Shelving: Profiles fit in light furniture, shelving, or storage, using aluminum’s strength-to-weight perks.

-

Architectural Elements: In buildings, profiles are used for curtain walls, window frames, and other parts needing durability and style.

Detailed Roll Forming Process of Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

Roll forming bends flat aluminum sheets into long, steady profiles. For banner stands, it’s key for making strong, shaped parts.

Proceso paso a paso

-

Material Preparation: Pick an aluminum alloy like 6061 or 6063, 0.5mm to 3mm thick, in coil form.

-

Uncoiling: The coil goes on an uncoiler, feeding the sheet at a controlled speed.

-

Initial Flattening: Leveling rollers flatten the sheet, removing any curves or waves.

-

Forming Stations: The sheet hits roll stations. Each pair of rollers bends it a bit more.

-

Progressive Bending: Each station adds to the shape, avoiding too much stress on the metal.

-

Final Shaping: After all stations, the sheet is fully formed into the profile.

-

Cutting to Length: A flying shear or rotary cutter slices the profile to exact lengths.

-

Post-Forming Operations: Profiles might get holes punched or surface treatments like anodizing.

-

Control de calidad: Auto systems check profiles for size and quality.

Advantages of Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

-

Eficacia en función de los costos: Fast speeds and low waste make it budget-friendly for big batches.

-

Consistency: Every profile comes out the same for easy assembly.

-

Velocidad: Churns out profiles at over 100 feet per minute.

-

Material Efficiency: Uses continuous strips with little scrap.

-

Flexibilidad de diseño: Makes all sorts of shapes and sizes.

Choose XinBo for Retractable Pull-up Banner Aluminum Stand Roll Forming Machine

XinBo, started in China in 2014, is a manufacturer with pro engineers and designers. XinBo offers Servicios ODM y OEM meeting global standards like UL, TUV, and CQC for markets like Europe and Canada.

Designing and CNC machining are done in-house, keeping steps in sync for fast delivery without skimping on quality. Each machine gets three inspections before shipping. Plus, machines fit into one 20-foot or 40-foot container, cutting shipping costs—a big deal for global clients wanting efficient, high-performance gear like the Retractable Pull-up Banner Aluminum Stand Roll Forming Machine. Contacto XinBo.

Publicaciones relacionadas

Buena calidad

XinBo máquina que hace CO. LTD es un fabricante profesional y exportador en la máquina de formación de rollos,

Ver más→

Español

Español Rusia

Rusia