How a Metal Signboard Cladding Panel Roll Former Transforms Modern Storefront Design

In today’s tough retail and business world, storefronts do more than open doors — they create the first look, show the brand’s style, and often set it apart. With growing use of modular building, personal touches, and need for steady quality in many spots, the way we make store-front cladding and signs has changed quietly but greatly.

At the center of this shift stands the Metal Signboard Cladding Panel Roll Former, a special cold-roll forming line built to shape metal cladding panels, pretty storefront panels, and signage skin with exact care, quick pace, and steady results.

What is a Metal Signboard Cladding Panel Roll Former — and How Does It Work?

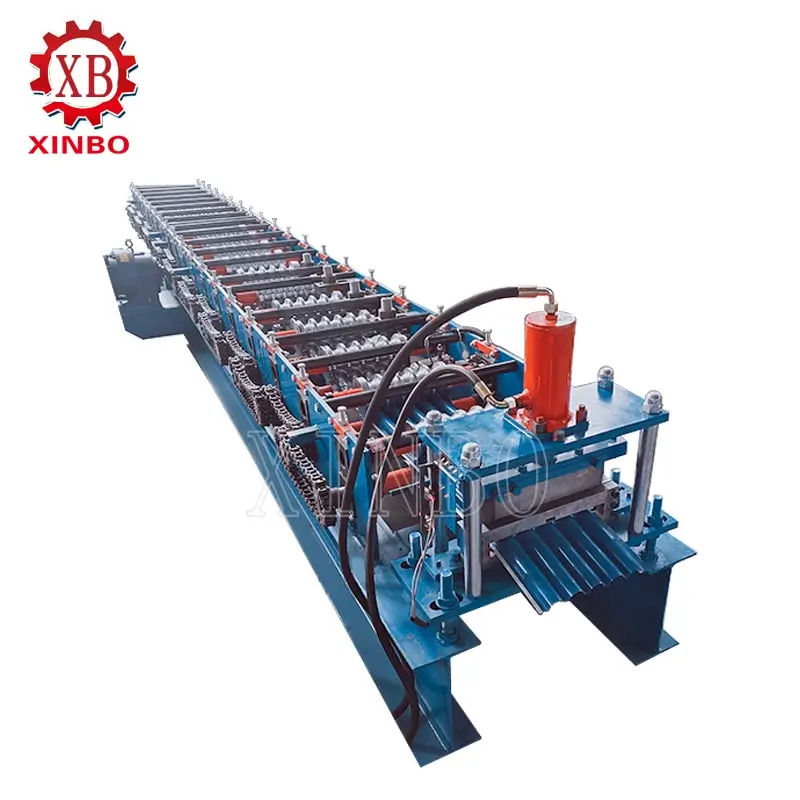

A Metal Signboard Cladding Panel Roll Former is basically a steady cold roll forming line. It grabs flat metal coils (aluminum, galvanized steel, pre-painted steel, etc.) and slowly bends them into set shapes and panel forms via many roller stops. Main parts usually have:

A decoiler (hydraulic or manual) for unwinding the coil.

Straightening and feeding guides to keep entry flat.

A group of forming rollers (cranked or shaped) which bit by bit bend the strip into the goal profile.

A PLC-controlled system for exact length control, cut-off, and optional punching or perforation.

A hydraulic (or servo) cutting and sometimes edge folding system.

The outcome: steady, high-exact metal wall panels or cladding panels with even cross-sections and little hand work.

Because of its strong automation and control, such a line — much like what could be named a storefront advertising cladding roll forming machine — can make hundreds of meters of panel each hour. This depends on material, profile, and later needs.

Materials, Panel Styles, and Design Flexibility

Material Options

Aluminum and pre-painted / coated steel coils: liked for light weight, weather-proof panels good for outside walls. Galvanized (GI) or PPGI steel: often picked when strength, low cost, and long life matter most. Stainless steel or special coated metals: chosen for top-end walls or fancy signage needing long wear and scratch protection.

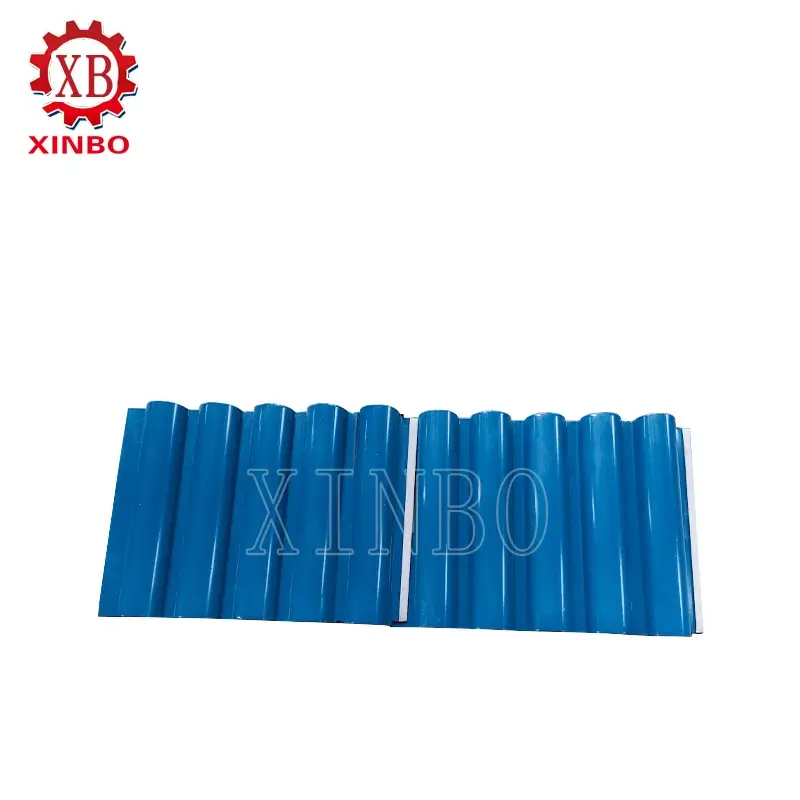

Panel Profiles and Styles

Thanks to the bendable nature of roll forming, makers can swap between various panel looks: Flat panels — simple, neat surfaces perfect for basic or current storefront walls. U-profile or linear panels — handy for straight building effects, trim parts, or slot-fixed signage systems (similar to U-profile linear advertising panel roll forming machines). Fluted / ribbed / corrugated panels — which bring depth, shadow lines, and visual feel; great for store-front decorative metal panel roll former uses or fluted signage cladding tasks. Custom profiles or interlocking systems — for hidden fasteners, snap-lock systems, or unseen joints. These allow smooth, ongoing walls without clear joins.

Because one metal panel roll forming line can be set (or re-set) to make different profiles, this way gives huge design choice without needing many materials or sellers.

Why It’s Transforming Modern Storefront & Signage Design: Five Key Contributions

1. Modular, Fast Deployment — From Production to Installation

Panels made by a roll former are often modular — standard widths, even profiles, and steady lengths. This modular build lets quick setup on site. It cuts build time and cost. Compared to old sheet metal work or hand bending, setup turns as easy as lining up, fixing, and sealing ready panels.

For store chains or many branches, this means same look and quicker finish for new spots or fixes.

2. Consistency & Reproducibility — Crucial for Brand Identity

For brands growing in many places, steady storefront look is key. Because the roll former uses a fixed tool set and CNC/PLC control, each panel made — whether flat, linear, or fluted — sticks to close limits. This makes sure façade panels from different runs (or even different plants) appear the same.

This steady repeat is a big plus over hand-made or manual folded metal signs.

3. Material & Finish Versatility — From Raw Coil to Finished Signage Skin

Roll forming lines can handle a broad range of materials and thicknesses. Paired with pre-painted coils, powder-coated or anodized finishes, and optional surface care, the end cladding panels can fit building looks, weather hold, and upkeep needs.

Also, by adding in-line punching or perforation and edge forming, it gets possible to build panels ready for built-in signs, back lights, or mount frames — all made in one steady flow (much like a storefront decorative metal panel roll former).

4. Cost Efficiency & High Throughput — Economical for Large Projects

Automated roll forming greatly cuts hand work, waste, and make time. Compared to classic sheet metal bending and custom work, the per-piece cost falls a lot — especially for big volumes.

For large fix-up or roll-out plans, the money put into a roll former is often gained back fast thanks to speed wins and less material loss.

5. Design Freedom & Integration — From Architecture to Signage to Decoration

Because roll forming lets making of varied panel types under one line — flat wall panels, linear trim strips, fluted pretty cladding, and even custom profiles — building, branding, and use can mix early in the plan stage.

For example: a linear panel might work as trim and LED channel; a fluted panel might act as both wall cladding and sound feature; a hidden-fastener design can hide fixings and give a clean, top surface. This level of mix shows the thought of “production-as-design,” where shape, use, and branding meet smoothly.

In short: the roll former is not just a tool — it is a strong helper of building creativity and brand show.

Beyond Signage: Broader Applications for Cladding Roll Forming in Commercial & Architectural Projects

Though the name stresses “signboard” or “wall cladding,” the uses go far past store signs. Common cases include:

Shopfront façades and exterior cladding — for retail chains, showrooms, shopping malls.

Standardized storefront panels for multi-branch brands — allowing quick rollout with steady visual style.

Interior accent walls, partitions, or decorative metal walls — e.g. for current office insides or business halls.

Linear metal trim, architectural fascias, sun-shade louvers, or cornice profiles (via U-profile or linear roll-formed profiles).

Ribbed or fluted wall cladding inside lobbies or corridors to create depth, texture, and shadow — exactly what a fluted signage cladding roll forming machine might produce.

Thus, the flexible nature of one roll forming line makes it a core tool not only for signage shops but also for full-scale building and façade contractors.

Technical & Quality Considerations: What to Watch Out For

When using roll-formed metal cladding for storefronts or signage, several tech points must be handled with care to keep quality and long wear:

Material thickness and roller tooling match: Thicker or harder materials need strong rollers and well-spaced forming stops. Wrong pair may cause cracking, unwanted spring-back, or uneven forming.

Precision feeding and length control: To keep tight panel-to-panel joints and even repeats (especially for fluted or U-profile panels), the PLC and encoder-based length control should be trusty.

Clean cutting and edge finishing: Hydraulic shearing (or flying shear) systems with proper edge bending or hemming make smooth ends. This cuts need for after-work before setup.

Surface treatment and weatherproofing: For outside signs or walls, pick pre-painted or coated materials with UV-strong finishes. Ensure good seam sealing. And think about thermal growth / shrink — key for long-term hold.

Hidden fastening systems & installation method: To keep looks good (no seen screws or rivets), many uses need hidden-fastening or snap-lock panel systems — which must be planned well when shaping the profile.

By handling these points with thought, designers and contractors can make sure roll-formed metal panels work well and look good over years of use.

FAQ (questions fréquentes)

Q: What kind of production speed and output can be expected from a metal cladding roll forming line?

A: Depending on material thickness, profile complexity, and downstream operations (e.g. punching, cutting, stacking), typical working speeds range from around 10–15 m/min up to 25–35 m/min (for some high-speed machines), enabling rapid output for large projects.

Q: Can the same line switch between flat, U-profile, and fluted panels?

A: Yes — many modern roll forming machines support changing tooling (roll sets, guides, cutters) so that one machine can produce flat façade panels, linear trim (U-profile), or fluted / ribbed cladding — giving flexibility for varied architectural requirements.

Q: What materials are recommended for outdoor storefront façades?

A: Aluminum or pre-painted / coated steel coils are preferable for exterior use due to their lightweight, corrosion resistance, and weatherproof coatings. For premium or high-end façades, coated stainless steel or treated aluminum can offer longer lifespan.

Transform your storefront vision into reality with XINBO — Expert consultation & project support

XINBO specializes in metal sheet roll forming (cold forming) machines and production lines for construction steel components.

Whether launching a new store, fixing an existing façade, or standardizing a brand chain across many spots, preparing the following info will help us give the best fit solution: desired panel material and thickness, maximum panel width and length, whether perforation or lighting integration is needed, and expected yearly production volume.

Contact XINBO’s technical team today to get a detailed proposal, sample panel, and quotation — and take the first step toward a modern, consistent, and cost-effective storefront upgrade.

Articles connexes

Bonne qualité

XinBo machine faisant CO. LTD est un fabricant professionnel et exportateur dans la machine de formation de rouleau,

Voir plus→

espagnol

espagnol Russie

Russie