How Decorative Metal Wall Cladding Panel Roll Forming Machines Enhance Building Design

What Are decorative Metal Wall Cladding Panel Roll Forming Machines?

Decorative Metal wall cladding panel machines à former des rouleaux are super cool tools in the building world. They’re also called cladding roll forming machines, wall panel roll forming machines, or metal panel forming machines. These nifty gadgets shape flat metal sheets into special profiles for covering walls inside and outside. Their big job is making top-notch panels that keep buildings strong and looking awesome.

How Do Decorative Metal Wall Cladding Panel Roll Forming Machines Work?

The working process of these machines involves a continuous bending operation in which a long strip of metal—usually coiled steel—is passed through a series of roller dies. Working flow: Manual decoiler—-Feeding Platform—-Main Roll Forming Machine—-Automatic Cutting System—Hydraulic Station—Computer Control Box—-Finished Panel Receiving Table. The machine uses pre-programmed instructions to ensure precision and consistency in the final product. The integration of a computer control box allows for real-time adjustments and monitoring, ensuring that each panel meets exact specifications.

What Types of Decorative Metal Wall Cladding Panels Can These Machines Produce?

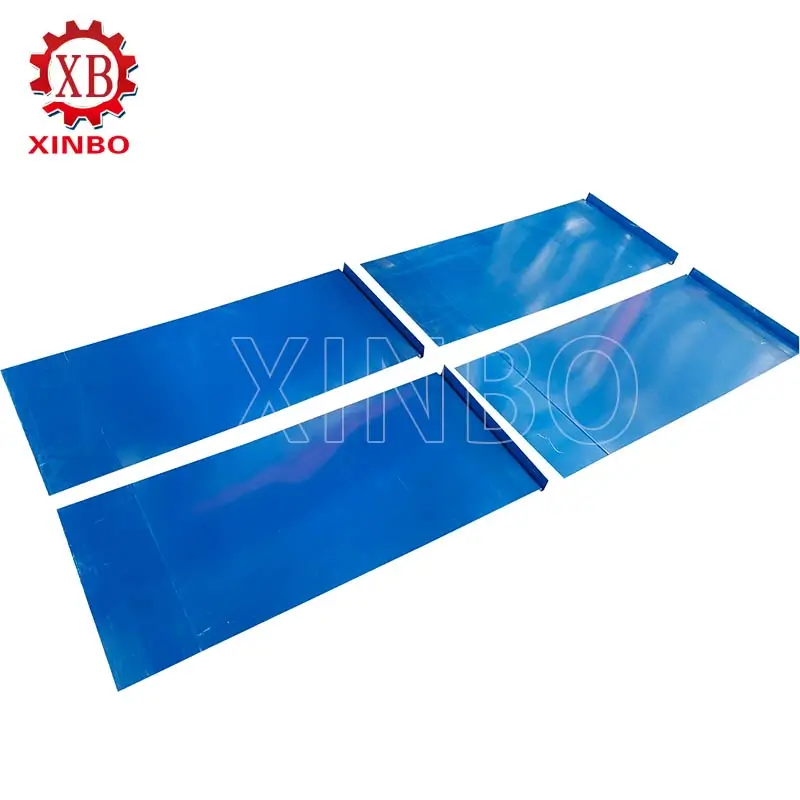

These machines whip up all kinds of panels, like corrugated sheets, trapezoidal panels, interlocking systems, and custom shapes. This gives builders and architects tons of choices for function and style. Roll forming machines make shapes, sizes, and thicknesses super steady, great for both normal and special projects.

Decorative Metal Wall Cladding Panel Roll Forming Machines Applications Across Building Types

Metal wall cladding panels from these machines are used all over:

- Bâtiments résidentiels: For tough, easy-to-keep exteriors.

- Commercial Complexes: To make slick, modern fronts.

- Installations industrielles: For strong shields against rough weather.

- Agricultural Buildings: Cheap fixes for barns and storage spots.

- Public Infrastructure: In airports, stadiums, and train stations for looks and use.

- Renovations: Turning old buildings into cool, energy-saving designs.

How Do Decorative Metal Cladding Machines Enhance Building Aesthetics and Design?

Aesthetic Versatility and Customization

Metal wall cladding panel roll forming machines are super flexible. They make all sorts of cladding profiles. This lets architects play with fun designs. Whoa, it helps make buildings that look amazing and fit modern trends. Custom setups can show off cultural vibes or brand style.

Durability and Material Versatility

These machines handle stuff like galvanized steel, aluminum, pre-painted steel, and stainless steel. The panels fight off rust, UV rays, and wild weather. Unlike wood or concrete, metal cladding panels last long with little upkeep.

Efficacité énergétique

These machines can make insulated metal panels (IMPs) or panels with built-in insulation. These cut down heat moving in or out. Yay, that means less energy for heating or cooling.

Précision et cohérence

The machines are super exact, making panels with tight fits and smooth looks. This makes putting them up easy with fewer mistakes. Precise panels help keep buildings solid.

Scalability and Speed

With speeds up to 40 meters a minute, these machines rock big projects without losing quality. They’re awesome for prefab building where time’s a big deal.

Sustainability

These machines waste less material when making panels. Plus, using recyclable stuff like aluminum and galvanized steel is great for the planet. This fits with green building goals like LEED.

Technological Advancements

Fancy roll forming machines use cool tech like IoT monitoring and AI tricks. These help check machines from afar, predict fixes, and keep quality high.

Versatility in Materials and Panels

These machines work with different metals, like steel gauges, aluminum from 0.019 to 0.040 inches, and copper from 16 to 20 oz. This gives designers lots of fun options.

Efficacité dans la production

These machines are zappy, swapping rollers in just 30 minutes to switch designs fast. On-site production cuts shipping costs too.

Custom Decorative Metal Wall Cladding Panel Roll Forming Machines by Xinbo: Leading Manufacturer in China

Xinbo machine making company, started in 2014, is a full-on manufacturer. They promise top quality and cool tech, thanks to their pro engineers, technicians, and workers. Xinbo makes custom roll forming machines for stuff like housing projects, commercial builds, industrial uses, and public projects.

Their products meet Euro standards like CE certification for worldwide use. Their design team builds machines to fit what customers want. They also make machines to fit in 20-foot or 40-foot shipping containers, saving big on transport costs.

Xinbo ships to Europe, the Middle East, Africa, North America, and South America—places like the United Kingdom, USA, Brazil, and Nigeria. Click here to Contact Xinbo for a instant quote.

FAQ (questions fréquentes)

Q1: What materials can be used with metal wall cladding panel roll forming machines?

A1: These machines handle galvanized steel, stainless steel, pre-painted steel, aluminum alloys, and copper sheets, based on what the project needs.

Q2: Are custom designs possible?

A2: Yup! Xinbo’s pro design team builds machines to match customer needs.

Q3: How do these machines support sustainable construction?

A3: They cut down on waste and use recyclable metals like aluminum or galvanized steel, helping green building practices.

Q4: Can they be used for prefabricated construction?

A4: Totally! Their fast output is perfect for modular building needing lots of same parts quick.

Q5: Is international shipping available?

A5: Yes! Xinbo designs machines to fit in 20-foot or 40-foot containers for easy, cheap shipping.

Q6: What industries benefit most from these machines?

A6: Construction (homes, shops, factories), public projects (airports, stadiums), agriculture (barns, storage), and renovations all love the cool looks and toughness of metal wall cladding panel roll forming tech.

Articles connexes

Bonne qualité

XinBo machine faisant CO. LTD est un fabricant professionnel et exportateur dans la machine de formation de rouleau,

Voir plus→

espagnol

espagnol Russie

Russie