How U Channel Roll Forming Machines Improve LED Strip Light Channel Production

U Channel Machines formant des rouleaux, also called U-section roll formers, metal channel forming machines, or profile roll forming systems, are super cool tools for making LED strip light channels. They turn flat metal into exact U-shaped channels. These channels hold LED strips, help with heat, and keep wires safe. This guide dives into how these machines make LED channel production awesome, covering their design, work, perks, and uses.

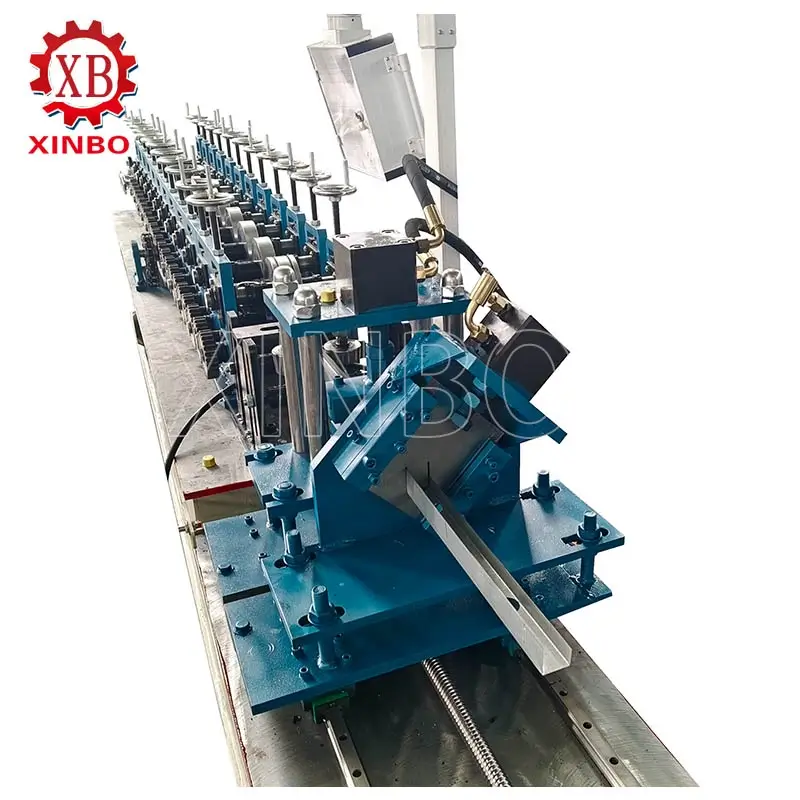

What is U Channel Roll Forming Machines

U Channel Roll Forming Machines are nifty gadgets that shape flat metal coils, like aluminum or steel, into U-shaped channels. They do this with a nonstop roll forming process. The metal goes through rollers that bend it bit by bit into the right shape. This makes every channel the same, which is key for lining up LED strips, handling heat, and protecting wires. These channels are strong and look pro, perfect for homes, shops, and factories.

U Channel Roll Forming Machines for LED Strip Light Channel Working Process

Making U channels for LED strip lights is a zippy process:

- Alimentation matérielle: A metal coil goes on a decoiler. It feeds the metal into the machine.

- Nivellage et pré-poinçonnage (facultatif): A leveling unit makes the metal flat. If needed, holes get punched for mounting or wiring.

- forme de rouleau: The metal slides through roller stations. Each one bends it a bit more into a U shape.

- Coupe: A hydraulic or flying shear chops the channel to the right length.

- Sortie: Finished channels land on a table for packing or more work.

This flow is super fast, wastes little, and is great for big LED lighting projects.

Types de machines de formation de rouleau à canal U

These machines come in different flavors for various needs:

- Machines de réglage manuel: Great for small jobs. They’re flexible for custom or low-volume work.

- Machines de réglage automatique: Built for big production. They need less human help, saving time and money.

- Systèmes hydrauliques: Have tough cutting tools for super exact and sturdy results, good for heavy jobs.

- Machines personnalisées: Made for special channel shapes or sizes, perfect for unique LED designs.

This mix lets makers pick the right machine for their project size and needs.

U Channel Roll Forming Machine Key Components

A typical U Channel Roll Forming Machine has these key parts:

- décoiler: Holds and feeds the metal coil smoothly.

- Unité d'alimentation: Keeps the metal straight as it heads to the rollers.

- Unité de formation de rouleau: Has lots of roller stations that shape the metal into a U.

- Système de coupe: Uses hydraulic or flying shears to cut channels to the right size.

- Système de contrôle: Runs on PLC or CNC with touchscreen for easy, auto control.

- Tableau de sortie: Grabs finished channels for simple handling or packing.

These parts team up for a smooth, zippy production line.

Key Features of U Channel Roll Forming Machine for LED Applications

U Channel Roll Forming Machines are awesome for LED strip light channels because of their cool features:

- Compatibilité matérielle: They handle aluminum, galvanized steel, and cold or hot-rolled steel. Lots of choices!

- Adjustable Rollers: Make channels for different LED strip widths, usually 10 to 20 mm.

- Vitesse de production élevée: Go 5 to 33 meters a minute, cranking out tons to meet demand.

- Precise Tolerances: Keep channels the same size for perfect LED strip fit and performance.

These make the machines super-duper for LED lighting needs.

U Channel Roll Forming Machine Applications in LED Production

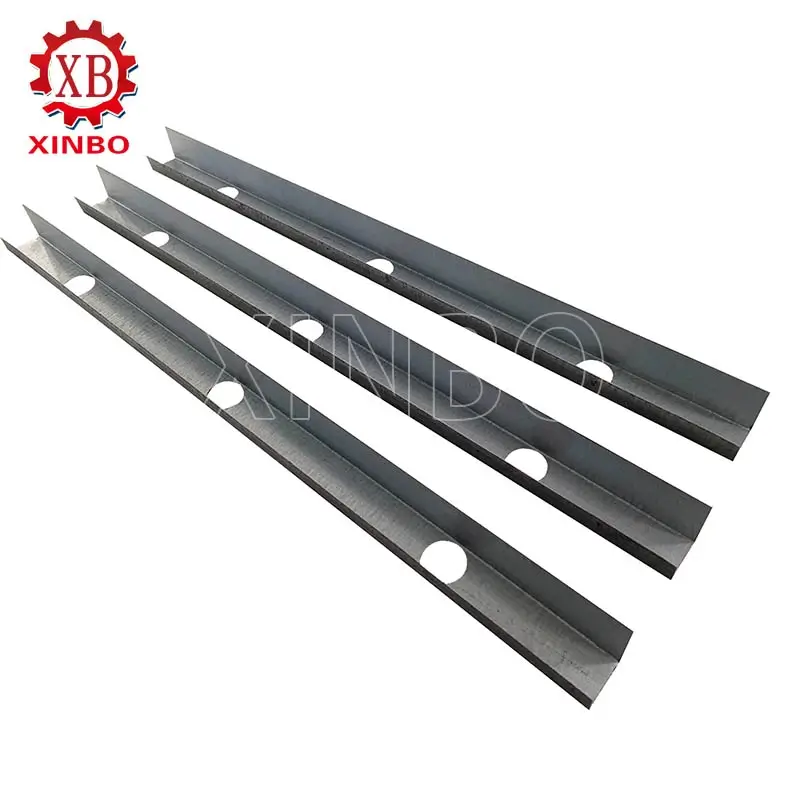

U channels from these machines are key for LED lighting:

- Clips de montage de canal LED: Look clean and pro on drywall or ceilings, boosting style.

- Canaux de montage en aluminium: Give strong support in shops and factories.

- Dissipation de chaleur: Aluminum channels cool down LED strip heat, making them last longer.

- Isolation électrique: Shield wires from damage, keeping things safe and reliable.

- Intégration esthétique: Add-ons like anodizing or powder coating make channels tough and pretty for fancy setups.

These uses show how U channels make LED lighting both useful and cool-looking.

U Channel Roll Forming Machine LED channel production Technical Specifications

The tech specs for U Channel Roll Forming Machines are built for LED channel needs:

- Gamme d'épaisseur du matériau: 0.3–1.2 mm

- Gamme de largeur de bobine: 20–200 mm

- Vitesse de production: 5–33 m/min

- Alimentation électrique: 380V/50Hz/3Phase (can be tweaked for needs)

- Matériel du rouleau: GCr15 steel with hard chrome coating for toughness

- Système de contrôle: PLC or CNC with touchscreen for easy use

These specs let the machines handle lots of materials and big production while staying precise.

|

Spécification |

Details |

|

Gamme d'épaisseur du matériau |

0.3–1.2 mm |

|

Gamme de largeur de bobine |

20–200 mm |

|

Vitesse de production |

5–33 m/min |

|

Alimentation électrique |

380V/50Hz/3Phase (customizable) |

|

Matériel du rouleau |

GCr15 steel with hard chrome coating |

|

Système de contrôle |

PLC/CNC with touchscreen |

LED strip light channels using U Channel Roll Forming Machines Manufacturing Process

The process for making LED strip light channels with U Channel Roll Forming Machines is super streamlined:

- Load Coil: Put the metal coil on the decoiler. It feeds into the machine.

- Flatten: A leveling unit makes the metal super flat.

- Punch Holes (Optional): Punch holes for mounting or wiring if needed.

- Shape Through Rollers: Rollers bend the metal into a U shape step by step.

- Cut: Hydraulic shears chop the channel to the right length.

- Surface Treatment (Optional): Add anodizing or powder coating for extra toughness and looks.

- Collect: Finished channels go to the output table for packing or more work.

This process is quick, cuts waste, and is perfect for big LED lighting runs, saving money and the planet.

Benefits of U Channel Roll Forming Machines

These machines bring tons of perks for LED strip light channel production:

- Haute vitesse: Go 5–33 m/min, cutting make time and worker costs for fast delivery.

- Précision: Make channels the same size for perfect LED strip fit and top performance.

- Flexibilité: Work with different metals and channel sizes for all kinds of projects.

- Économie de coûts: Waste less material and make faster, lowering costs.

- Strength and Durability: Channels are tough and rust-proof, lasting long in any setting.

These make U Channel Roll Forming Machines a smart, reliable pick for LED channels.

Défis

Even with all the cool stuff, these machines have some hurdles:

- High Initial Cost: They cost a lot upfront, tough for small companies or startups.

- Besoins d'entretien: Need regular checkups to keep running great and lasting long.

- Safety Requirements: Must follow strict safety rules, which add costs but keep workers and gear safe.

These bumps are worth it for the big efficiency and quality wins.

Manufacturer Information: XinBo

XinBo started in China in 2014, is a top maker of U Channel Roll Forming Machines. With their own workshop and CNC gear, they make custom solutions for customers. Their products are CE-certified and sold in places like Europe and Africa. XinBo offers awesome after-sales help, like setup and training, so customers get the most out of their machines.

XinBo Customization of U Channel Roll Forming Machines

Personnalisation is a big deal for U Channel Roll Forming Machines. XinBo’s skilled engineers draw up plans to match exact project needs. This lets them make channels with unique shapes or sizes, perfect for special LED lighting designs.

Certifications

U Channel Roll Forming Machines from trusted makers like XinBo have certifications like:

- UL

- TUV

- CE

- CQC

- ROHS

- REACH

These prove the machines are high-quality, safe, and meet global standards, giving buyers peace of mind.

FAQ Answers

Common questions about U Channel Roll Forming Machines include:

- Materials: They handle aluminum, galvanized steel, cold-rolled steel, and hot-rolled steel.

- Vitesse de production: Goes from 5 to 33 m/min, great for big or medium projects with a quality focus.

- Suitability: Perfect for large-scale production but flexible for smaller, quality-driven jobs.

Additional Insights from Industry Sources

- Dissipation de chaleur: Aluminum channels from roll forming machines are key for cooling LED strip heat, making them last longer.

- Versatilité dans les applications: Channels work in under-cabinet lighting, cove lighting, and retail displays, as suppliers note.

- Efficacité dans la production: Roll forming machines are known for high precision and cost-saving in making metal channels for LED lighting and more.

Articles connexes

Bonne qualité

XinBo machine faisant CO. LTD est un fabricant professionnel et exportateur dans la machine de formation de rouleau,

Voir plus→

espagnol

espagnol Russie

Russie