How Container House Bottom Side Rail Roll Form Machines Improve Builds

The container house bottom side rail rolvormende machine is special equipment. It makes strong rails for the base of container homes. These machines speed up production. They also boost the durability and function of container homes.

With careful design, these machines create tough rails. The rails support floors, join walls, and handle tough weather in modular container housing.

What is a Container House Bottom Side Rail Roll Forming Machine?

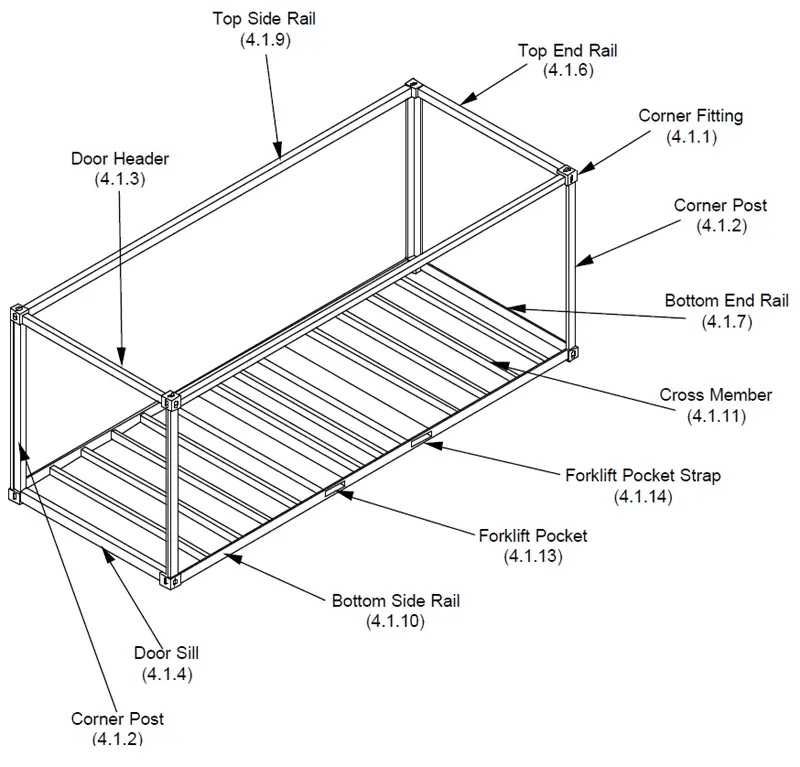

A container house bottom side rail roll forming machine is a type of cold roll forming equipment specifically engineered to fabricate the bottom side rails used in container homes. These rails typically run along the lower edges of a container’s frame and are crucial for maintaining structural integrity. They are usually made from corten or galvanized steel with thicknesses ranging from 2.0mm to 4.5mm.

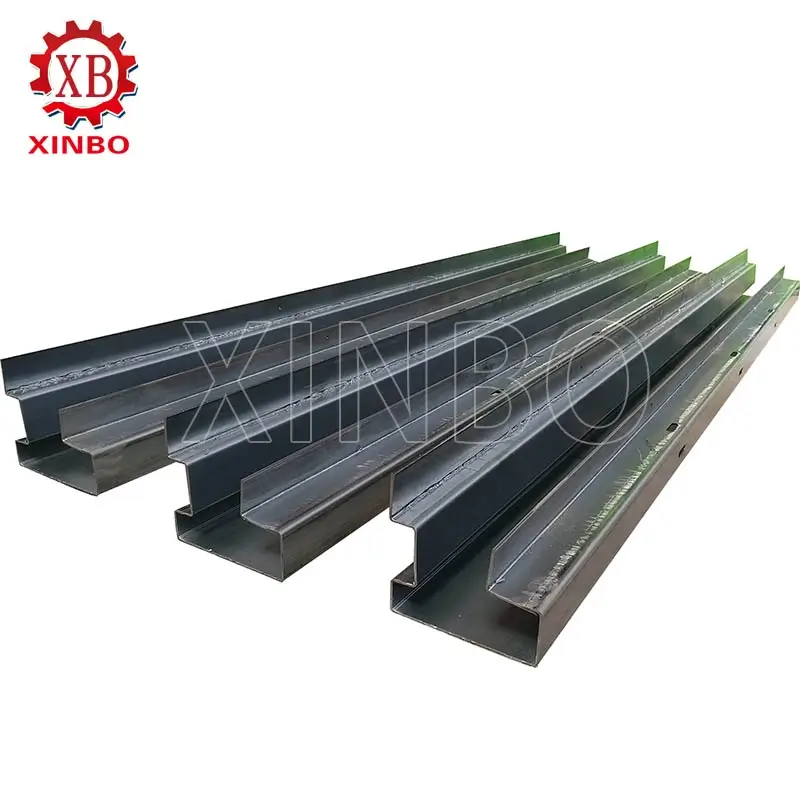

In essence, roll forming involves the continuous bending of a long strip of metal sheet through a series of rollers to achieve a desired cross-sectional shape. The machine produces Z-type, C-type, or U-shaped channels tailored for specific construction needs. The output integrates seamlessly into modular designs, often including forklift pockets or lashing rings depending on container specifications.

How Container House Bottom Side Rail Roll Form Machines Works

The operation of a container house bottom side rail roll forming machine relies on the principle of progressive cold forming, where a flat metal coil is gradually shaped into a complex profile through sequential bending stages. The process starts with uncoiling steel sheets which are then leveled and fed into the machine.

Each roller station consists of paired top and bottom rollers that apply pressure to specific sections of the strip, forming flanges, webs, and edges step by step. A programmable logic controller (PLC) manages all operations including punching holes and cutting lengths through flying shears. This automation ensures consistency while minimizing waste.

The use of oversized shafts and robust frames allows the machine to handle thick materials like 4.5mm corten steel without compromising quality. Post-forming straightening units ensure final products meet tight tolerances required in modular assemblies.

Key Components of Container House Bottom Side Rail Roll Form Machines

A container house bottom side rail roll forming machine comprises several interconnected components, each contributing to its functionality and precision. These include:

-

Main Frame: Typically constructed from H450 welded steel for maximum rigidity.

-

Uncoiler: Holds large coils and feeds them into the system.

-

Roll Forming Stations: Usually 22 or more stands equipped with alloy steel rollers.

-

Drive System: Gearboxes or chains powered by variable frequency drives.

-

Hydraulic Units: Operate punching presses and cutting systems.

-

PLC Control Panel: Allows operators to input length, quantity, and profile parameters.

-

Veiligheidskenmerken: Emergency stops, guards, and sensors ensure safe operation.

Secondary components include punching dies for holes/slots, straightening units to flatten profiles, and a cutoff shear (mechanical or hydraulic) for precise trimming.

Workflow of Container House Bottom Side Rail Roll Form Machines

The workflow of a container house bottom side rail roll forming machine is a streamlined, automated sequence that ensures high efficiency. It starts with material preparation: a steel coil is loaded onto the uncoiler, where it’s straightened and fed into the entry guide.

Step 1: Feeding and Leveling – The strip enters leveling rollers to remove coils and ensure flatness.

Step 2: Roll Forming – The core phase, where the strip passes through sequential stations. Each station bends a portion—e.g., first forming the web, then flanges—until the full Z-type or C-type profile emerges after 22 steps.

Step 3: In-Line Processing – Punching for forklift pockets or lashing rings happens here, using hydraulic presses synchronized with the line speed.

Step 4: Straightening and Cutting – Post-forming, rollers straighten the rail. A flying shear cuts it to specified lengths (e.g., 20ft or 40ft equivalents) without halting production.

Step 5: Collection and Quality Check – Rails move to run-out tables for inspection, measuring tolerances and surface quality.

The entire process is controlled via PLC, with sensors monitoring speed and alignment. For container rails, workflows often include welding edges if needed for closed profiles. Downtime is minimal, with setups for multiple profiles via quick-change tooling. This workflow supports batch production, from hundreds to thousands of rails per shift

Applications of Container House Bottom Side Rail Roll Form Machines

Container house bottom side rail roll forming machines find extensive use in modular construction, particularly for prefabricated homes, offices, and temporary structures. Primary applications include:

-

Modular Housing: Producing rails for container homes, enabling quick assembly of portable bedrooms, kitchens, or full residences.

-

Commercial Buildings: For stores, meeting rooms, or warehouses, where rails form stable bases.

-

Disaster Relief: Rapid deployment of shelters using rails for sturdy frames.

-

Industrial Uses: In shipping containers for cargo, with rails supporting heavy loads.

-

Infrastructure: Rails in guardrails, beams for bridges, or frames in solar panel arrays, extending beyond housing.

Versatility allows production of related parts like top beams or posts, supporting diverse sectors like transportation (train cars, trailers) and energy (solar mounts).

Advantages of Container House Bottom Side Rail Roll Form Machines

These machines offer numerous advantages over traditional fabrication methods:

Efficiency: High-speed production (up to 450 FPM) with minimal waste, making them ideal for mass manufacturing environments.

Precision: Tight tolerances and uniform profiles ensure reliable fits in assemblies.

Other benefits include:

-

Energy-efficient cold-forming technology

-

Lower labor requirements due to automation

-

Capability to handle various material grades

-

Easy integration into existing production lines

-

Scalability for different project sizes

Additional Insights: Maintenance, Innovations, and Industry Trends

Maintenance is crucial for longevity: regular lubrication of rollers, alignment checks, and tooling inspections prevent breakdowns. Innovations such as CNC controls allow real-time adjustments during operation.

Emerging trends include hybrid systems that integrate welding modules directly into roll forming lines—ideal for producing closed-section profiles used in high-load applications.

Industry-wide focus on sustainable construction has increased demand for machines capable of producing recyclable steel components efficiently.

Challenges and Considerations

While highly effective, these machines do present some challenges:

Challenges include material variability—thicker steels require robust machines—and setup times for profile changes.

Operators must be trained thoroughly due to the complexity of automated systems. Safety features must be rigorously maintained given high-speed operations involving heavy materials.

Initial capital investment can be significant; however, return on investment is realized quickly through high-volume production capabilities.

Case Studies and Examples

In disaster relief scenarios across Africa or Southeast Asia, prefabricated shelters built using these rails have proven effective due to their quick deployment times.

In renewable energy sectors such as solar farms in Europe or North America, similar roll formed profiles serve as mounting structures—demonstrating cross-industry versatility.

Construction companies building mobile offices or pop-up retail spaces rely heavily on consistent-quality rails produced by these machines for structural integrity.

custom your Container House Bottom Side Rail Roll Form Machines from XinBo

If you’re looking to invest in reliable container house bottom side rail roll form machines tailored specifically to your project needs, XinBo machine making company is a 100% manufacturer which established since 2014.

Our roll forming machines are be designed and made according to customers’ requests. Whether you’re producing Z-shaped beams or custom-length C-channels, our professional designing team will design the machine total according to customer requirements.

Additionally, we will design roll forming machines to be fit into one 20feet or 40feet container, optimizing logistics costs. We supply customer guaranteed qualified products and “product designing, assembling, installation, and after-sales service” one-stop superior service.

We warmly welcome ODM and OEM requirements so your unique specifications are always accommodated.Contact XinBo today.

Gerelateerde berichten

Goede kwaliteit

XinBo-machine die CO. LTD maakt is een professionele fabrikant en exporteur in rolvormende machine,

Bekijk meer→

Spaans

Spaans Rusland

Rusland