Roll Forming Machines for Folding Slats of Roll-Up Camping Tables

Overview of Roll-Up Camping Tables

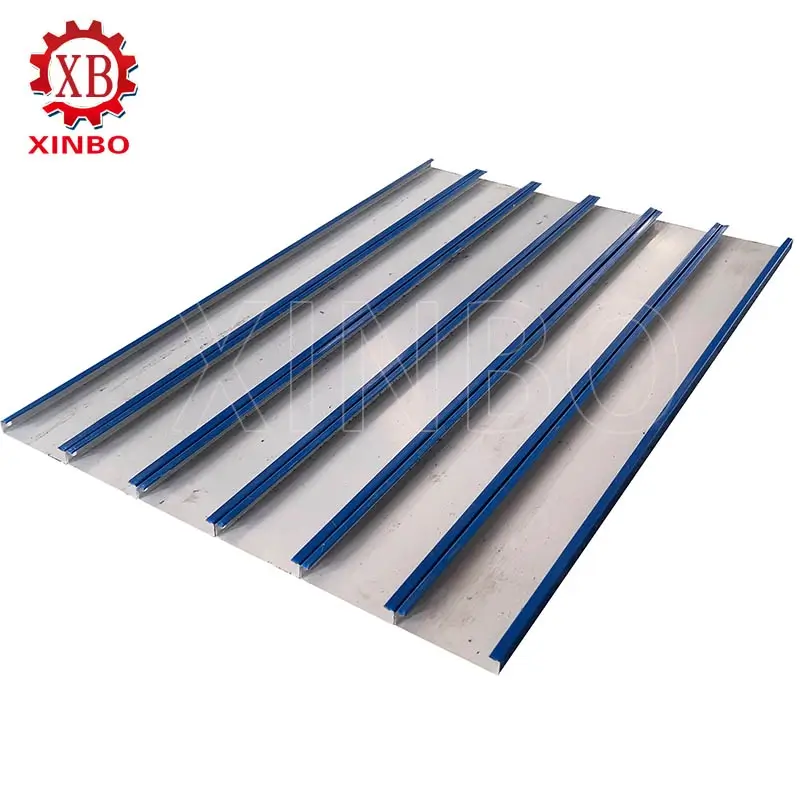

Roll-up camping tables are a hit for outdoor fun. They are cherished for being easy to tote, small when stowed, and firm for tasks like eating, cooking, or playing games. The folding slats that create the tabletop are crucial to their use. These slats allow the table to open for use and fold into a small bundle for carrying.

Design of Folding Slats

The design of folding slats is key for roll-up camping tables. These slats need to be light, strong, and able to make a steady surface while staying tiny when packed. Important design points include:

Material

- Aluminio: The top pick because it’s light, fights rust, and is simple to mold. Aluminum alloys like 6061 or 6063 are often used for their toughness and ease of shaping.

- Outros materiais: Some designs use wood, often layered for strength, or composites. But aluminum is preferred for modern roll-up tables because it performs well outdoors.

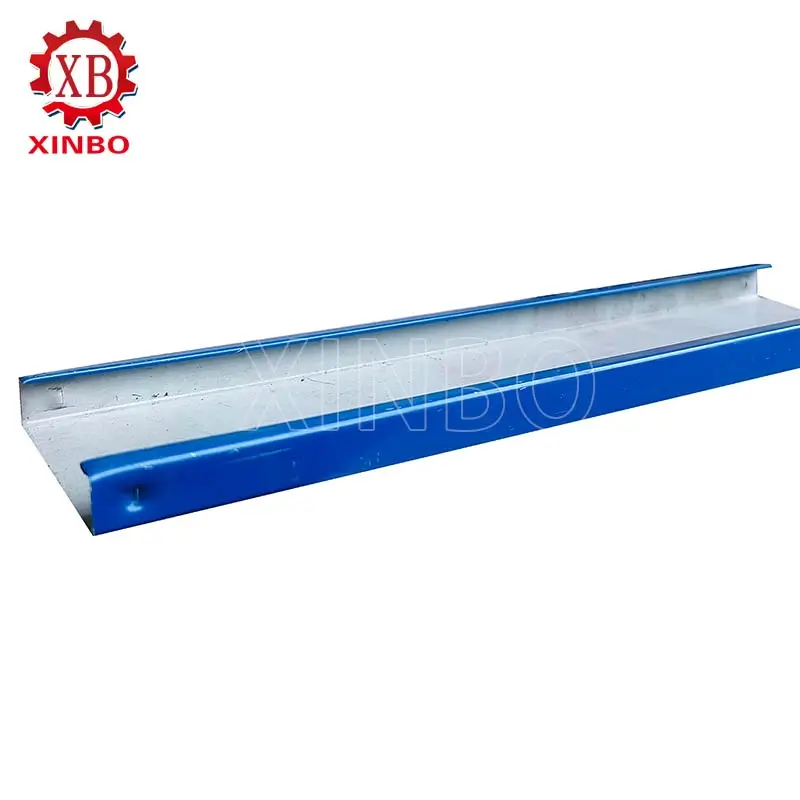

Profile

- Flat Slats: Basic, box-like shapes that are simple to craft and assemble.

- Interlocking Slats: Have grooves or rims to join tightly, forming a solid tabletop.

- Curved or Clamshell Slats: Used in some designs for added strength or style, but not common for camping tables.

- The profile must let slats roll up small, often by fitting together or bending slightly.

Connection Mechanism

- Hinges or Clips: Some tables use hinges to connect slats, making folding and unfolding easy. Clips or fasteners may hold slats to the table frame.

- Interlocking Design: Some slat shapes lock together without extra parts, cutting weight and complexity.

- Rollability: Slats must roll into a tight bundle, often held by a strap or stored in a carry bag.

Size and Weight

- Lightweight: Slats add to the table’s total weight, usually under 15 pounds, with slats being a major part.

- Load Capacity: Must support 100-400 pounds, based on the table’s design, needing strong but light materials.

- Dimensões: Slat lengths range from 20-48 inches depending on table size. Widths are typically up to 300mm to fit standard roll forming machines.

Características Adicionais

- Heat Resistance: Aluminum slats often resist heat, great for cooking tasks.

- Water Resistance: Vital for outdoor use, aluminum’s rust resistance is a big plus.

- Ease of Cleaning: Smooth surfaces or coatings make slats easy to wipe clean.

Materials Used

The material for folding slats is chosen for portability, toughness, and weather resistance. Here are the main materials and their features:

Aluminio

- Avantagens:

- Light: Strong for its weight, ideal for portable camping gear.

- Rust Resistance: Stays strong in wet or humid conditions.

- Formability: Easy to mold into complex shapes with roll forming.

- Heat Resistance: Good for tables used with hot cookware.

- Alloys: Common ones include 6061 (tough) and 6063 (easy to mold).

- Espessura: Usually 0.5-1.2mm, with heavy-duty uses up to 2mm.

- Gauge: Matches 26-16 gauge for similar uses, though aluminum’s density differs from steel.

Steel

- Usage: Rare in camping tables due to weight but used in items like roller shutters.

- Avantagens: Tougher than aluminum, good for heavy-duty tasks.

- Considerations: Needs galvanization or coatings to stop rust, adding weight and cost.

Wood

- Usage: Seen in some special or older designs, often layered with vinyl or other coatings.

- Avantagens: Looks nice and feels warm but is heavier and less sturdy.

- Considerations: Can be damaged by water, so it’s less common in modern designs.

Processo de Fabricação de Roll Forming Machines for Folding Slats of Roll-Up Camping Tables

Making folding slats for roll-up camping tables involves several steps. Roll forming is the main method. Here’s a clear overview:

Step 1: Material Preparation

- Input: Aluminum sheets or coils, typically 0.5-1.2mm thick and up to 300mm wide.

- Controlo da qualidade: Check for defects to ensure steady material quality.

- Feeding: Coils are loaded into a decoiler for smooth feeding into the roll forming machine.

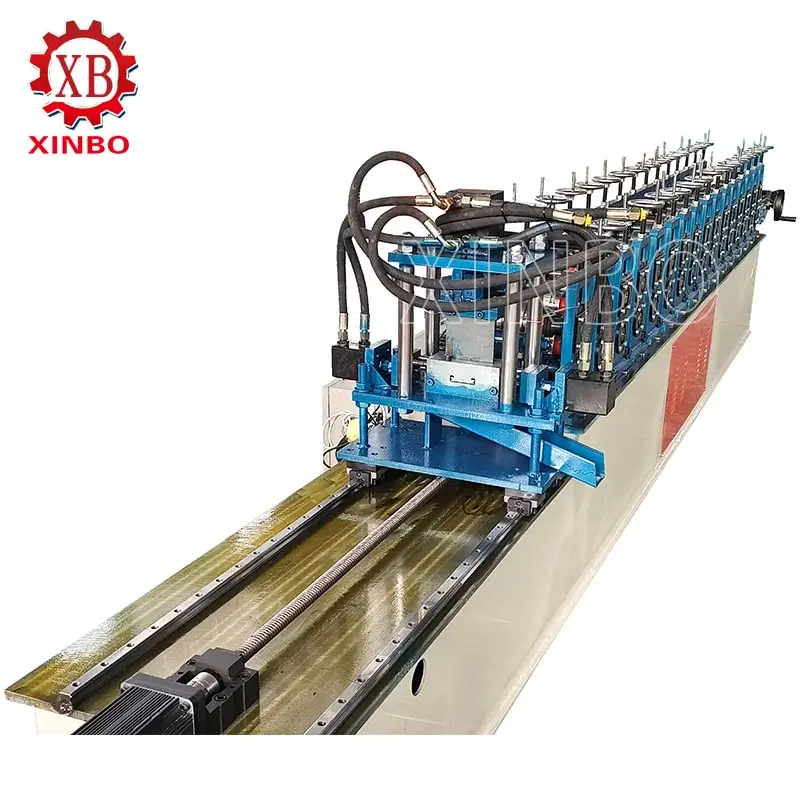

Step 2: Roll Forming

- Process: Roll forming moves the aluminum sheet through rollers that slowly shape it into the desired form.

- Machine Setup:

- Decoiler: Uncoils the metal sheet.

- Roll Stations: 10-18 stations with rollers that shape the metal bit by bit.

- Forming Speed: 0-12 meters per minute, adjustable for material and profile needs.

- Profile Design: Rollers are crafted to make flat, interlocking, or curved slat shapes, based on the table’s design.

Step 3: Cutting

- Method:

- Flying Cut-Off Saw: Cuts the formed profile to the right length.

- Hydraulic Cutter: Another option for exact cuts, often used for thicker materials.

- Precisião: Cutting tolerance is typically ±2mm to keep slat lengths even.

- Length: Slats are cut to specific lengths (e.g., 20-48 inches) based on table size.

Step 4: Punching or Drilling (Optional)

- Purpose: Holes or slots may be added for assembly or functions like ventilation.

- Method: In-line punching tools in the roll forming line for efficiency.

- Customization: Punching patterns match the table’s assembly needs.

Step 5: Finishing

- Deburring: Removes sharp edges from cut or punched areas.

- Limpar: Clears slats of debris or oils.

- Coating: Optional anodizing or protective coatings improve durability and looks.

Componentes chave e Especificações de Máquinas de Formação Roll for Folding Slats of Roll-Up Camping Tables

Roll forming machines are special tools made to create long, even metal profiles. For folding slats of roll-up camping tables, these machines must handle thin aluminum sheets and make precise shapes.

Componentes chave

- Decoiler: Holds and uncoils the aluminum coil.

- Roll Stations: 10-18 pairs of rollers that shape the metal gradually.

- Drive System: Chain or gear-driven to move the metal through rollers.

- Cutting Station: Flying saw or hydraulic cutter for accurate length cutting.

- Sistema de Controlo: PLC-based (e.g., Panasonic PLC with Omron encoders) for exact control.

- Punching Tools: Optional for adding holes or slots during forming.

Especificações

The table below shows typical specs for roll forming machines suited for camping table slats, based on machines for similar uses like roller shutter slats:

|

Parâmetro |

Especificação |

|

Tipo de material |

Aluminum, galvanized steel, stainless steel |

|

Espessura Material |

0.5-1.2mm (up to 2mm for heavy-duty uses) |

|

Largura do material |

Up to 300mm |

|

Roll Stations |

10-18 stations |

|

Velocidade de Formação |

0-12 m/min |

|

Main Motor Power |

5.5 kW |

|

Hydraulic Power |

3 kW (Cutting) |

|

Fly-Saw Power |

2.2 kW |

|

Cutting Tolerance |

±2mm |

|

Sistema de Controlo |

PLC (e.g., Panasonic), Omron encoder, inverter |

|

Electricity |

380V/3ph/50Hz |

Adaptability

Machines for roller shutter slats or rolling door slats can be tweaked for camping table slats. This is done by adjusting roll stations to match the slat profile. Features like in-line punching help add assembly holes. Post-cutting allows flexible slat lengths.

Advantages of Roll Forming

- Eficiência: Fast production for large-scale manufacturing.

- Precisião: Creates even profiles with tight tolerances (±2mm).

- Versatilidade: Can form complex shapes with multiple bends.

- poupanças de materiais: Reduces waste compared to stamping or machining.

- Efeitividade de custos: Budget-friendly for high-volume production.

Challenges and Considerations

- Design Specificity: Custom tooling is needed for specific slat profiles, raising setup costs.

- Espessura Material: Thin aluminum (0.5-1.2mm) needs careful handling to avoid bending.

- Production Volume: Roll forming is best for high-volume runs. Low-volume runs may suit methods like laser cutting better.

- Customization: Adjusting machines for camping table slats may need engineering to tweak roller designs.

Market Context

Roll-up camping tables are popular for car camping, RVing, and outdoor activities, as noted in reviews from OutdoorGearLab and REI Co-op. The need for light, sturdy, and portable tables drives demand for efficient manufacturing like roll forming. This process makes high-quality slats at scale.

Custom Roll Forming Machines for Folding Slats from XinBo

XinBo machine, a 100% manufacturer started in China in 2014, offers custom roll forming machines for folding slats of roll-up camping tables. Contact the expert team at +8615003216790 or email serena@cnxinbo.net to discuss needs, request technical drawings, or get a quote. With over 10 years of experience in designing and making high-quality metal shaping solutions, XinBo provides tailored machines to meet specific needs. The company ensures quick delivery and top product quality with new tech and dependable service.

Conclusão

Roll forming machines are ideal for making folding slats for roll-up camping tables. They offer a fast and precise way to shape aluminum into light, strong profiles. The design of these slats needs careful thought about material, profile, and connection methods to ensure portability and stability. By using machines similar to those for roller shutter slats, manufacturers can meet the growing need for portable camping furniture. Further study into specific slat designs or unique processes could boost production efficiency. The principles here provide a strong base for understanding the manufacturing process.

Postos relacionados

Boa qualidade

A máquina XinBo que faz CO. LTD é um fabricante profissional e exportador em máquina de formação de rolos,

Vê mais→

Espanhol

Espanhol Rússia

Rússia