Automatic Adjustable CZ Purlin Cold Roll Forming Machine: C & Z Profiles in One Line

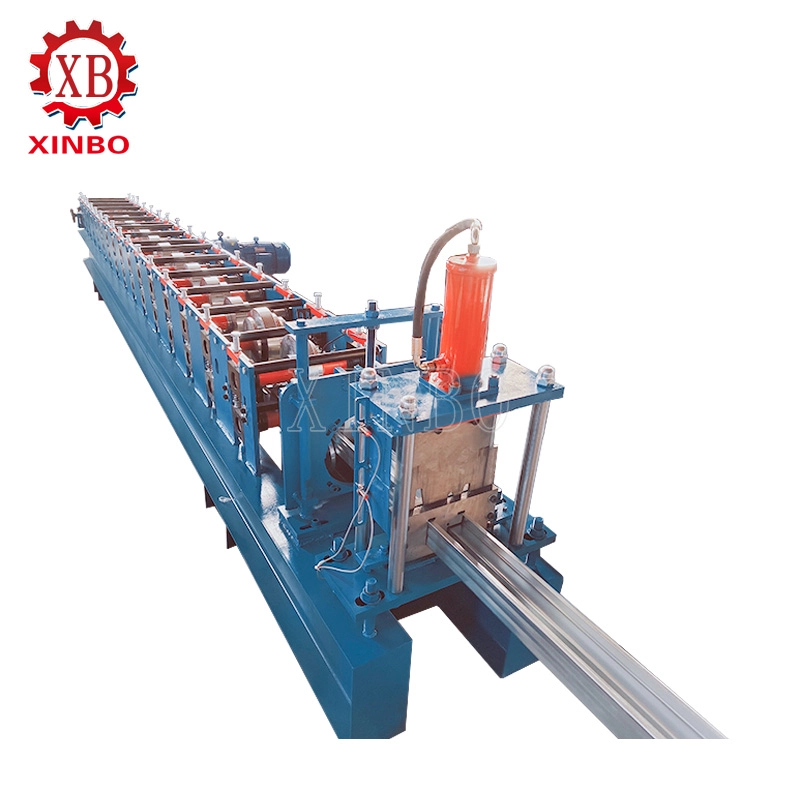

ya Automatic Adjustable CZ Purlin Cold Roll Forming Machine: C & Z Profiles in One Line leads modern steel profile production methods. This well-combined system lets manufacturers make both C purlins and Z purlins on one single line. Changeover time stays very low. As a result, it greatly boosts work efficiency in steel structure making.

In the quick-moving construction and prefab building field today, the cz purlin roll forming machine acts as a main tool. It creates light yet strong secondary parts for roofs, walls, and raised floors. Producers around the world count on steady china cz purlin roll kuunda mashine options. These give even quality and good costs. Top china cz purlin roll forming machine factory setups put together strong machine builds, exact controls, and easy-to-use panels. They handle many different project needs.

What Is an Automatic Adjustable CZ Purlin Cold Roll Forming Machine?

This machine focuses on cold roll forming. It turns galvanized or hot-rolled steel coils into exact C and Z purlins. It does this step by step through bending stations. Old ways needed hand roller swaps. However, the automatic adjustable cz purline cold roll forming machine relies on PLC systems. These adjust sizes and switch from C to Z shapes smoothly. Often the change happens in just minutes.

The main steps start with uncoiling the steel strip. Next comes leveling to fix coil bend. Then optional pre-punching adds holes. These holes help with bolting later. After that, roll forming uses many stations. Usually there are 16-20 or even more for better accuracy. At the end, hydraulic cutting makes the right lengths. Once formed, profiles come out on a run-out table or stacking setup.

Key technical points include:

-

Material thickness handling: Usually 1.0-3.5mm, with some heavy-duty models up to 4-5mm.

-

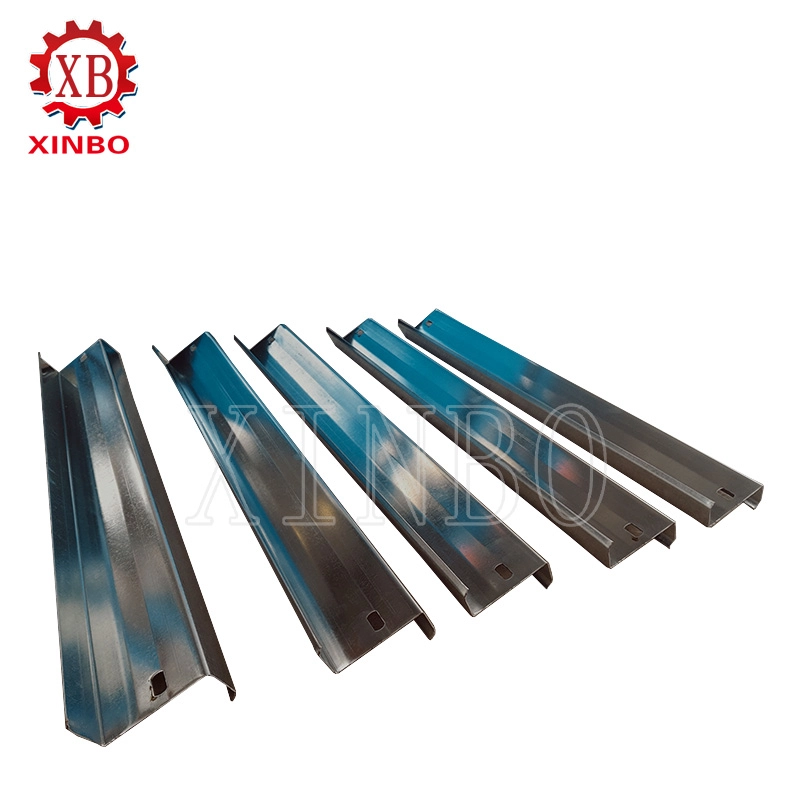

Profile range: C purlins from 80-300mm web height, flanges 35-80mm; Z purlins similar, with lip edges 10-25mm.

-

Speed: 15-35m/min or higher in advanced configurations, depending on punching and material.

-

Automation: Servo-driven adjustments for size changes, hydraulic or servo punching, and universal cutters that adapt without mold swaps.

The advanced cz purlin roll forming machine adds features. These include gearbox or chain drives for steady power. Rollers use strong materials like GCr15. They get heat-treated to HRC58-62. Bases stay reinforced. This cuts vibration and keeps things reliable over time.

Key Advantages of Producing C & Z Profiles in One Line

A major plus of the automatic cz purlin roll forming machine is how flexible it stays. Old methods needed separate lines for C and Z profiles. That raised costs and took more space. Now both types come from one line. Operators gain more options. C profiles give great strength against pressing down. Z profiles work better as continuous beams. Their overlap design suits them well for roof purlins in big-span buildings.

This best cz purlin roll forming machine setup cuts waste. Precise length control uses encoders. Accuracy reaches ±1mm. It also lowers labor needs. Quick switches happen in 3-5 steps or even fully automatic. Factories respond fast to new jobs. Output rises for warehouses, industrial sites, or pre-engineered metal buildings (PEB).

On top of that, built-in punching on webs and flanges makes later assembly easier. Holes line up right for bolts. No extra drilling becomes necessary.

Technical Components and How They Ensure Precision

A good automatic adjustable cz purlin cold roll forming machine has several key parts:

-

Uncoiler/Decoiler: Hydraulic or manual, 5-10 ton capacity to handle heavy coils smoothly.

-

Leveler/Straightener: Multi-roller systems eliminate coil curvature for uniform feeding.

-

Servo Feeder and Punching Unit: Precise hole placement (round, oblong, or slotted) controlled by PLC for custom spacing.

-

Roll Forming Stations: Progressive rollers shape the strip gradually. Rollers are ground twice for precision, with shafts (often ø75-95mm) hardened to prevent deflection.

-

Mfumo wa kukata: Fly or post-cut hydraulic shears with universal blades that adjust for varying sizes, ensuring burr-free ends.

-

Mfumo wa Udhibiti: Touchscreen PLC interfaces for inputting parameters like length, quantity, punch positions, and profile type. Encoder feedback ensures repeatability.

These parts team up well. They create profiles with straightness errors ≤0.3mm/m. Dimensions stay within ±0.5mm. This meets tough industry rules.

Applications in Modern Construction

C and Z purlins work as secondary parts in steel buildings. They support roof covers, wall panels, and solar setups. Factories, warehouses, and farm buildings use them. They offer light options compared to hot-rolled pieces. Still, they hold strong loads.

The automatic cz purlin roll forming machine does well in big production runs. Pre-engineered buildings often need custom work. Punched holes allow fast setup on site. This drops labor and shortens build time.

Choosing the Right CZ Purlin Roll Forming Machine Supplier

Picking the right cz purlin roll forming machine supplier matters a lot for success over time. Seek suppliers with solid design skills. They should do strict tests before shipping. Good after-sales help counts too. This includes setup, training, and ongoing tech aid for life. A trusted partner fits the machine into daily work. It manages special needs like wider profiles or better automation.

Choose ones that stress quality parts. Think precision-ground rollers and strong electric setups. These lower stoppages and repair costs.

This equipment has changed a lot. It moved from hand single-profile units to today’s automatic adjustable cz purline cold roll forming machine. The shift shows progress in controls and speed. It becomes a wise choice for growing output.

Maswali ya kawaida

Q1: What materials can the Automatic Adjustable CZ Purlin Cold Roll Forming Machine process?

It typically handles galvanized steel, cold-rolled steel, or hot-rolled coils with thicknesses from 1.0mm to 3.5mm (or higher in heavy-duty models), ensuring corrosion resistance and structural integrity.

Q2: How long does it take to switch between C and Z profiles?

In advanced models, switching can occur in minutes via PLC-controlled adjustments or quick manual steps, minimizing production interruptions.

Q3: Does the machine require frequent roller changes for different sizes?

No—the automatic size adjustment feature allows profile changes (e.g., web height, flange width) without replacing rollers or spacers, enhancing versatility.

Q4: What maintenance is typically required?

Regular lubrication of moving parts, cleaning of rollers, and periodic checks on hydraulic and electrical systems. High-quality builds ensure low maintenance needs.

Q5: Can punching patterns be customized?

Yes, PLC programming allows flexible hole spacing, shapes, and quantities to suit specific project requirements.

Ready to Elevate Your Purlin Production?

Invest in the Automatic Adjustable CZ Purlin Cold Roll Forming Machine today. It brings top efficiency, exact results, and flexibility for C and Z profiles. Quick servo size changes cover 80–300 mm web. Universal cutting works well. Speeds reach up to 30 m/min. Changeover drops fast. Labor goes down. Waste shrinks too. Tight tolerances stay at ±0.5 mm.

As a specialized china cz purlin roll forming machine factory, ya XINBO supplies reliable, strong machines. They use hardened GCr15 rollers, solid frames, and simple PLC controls. Our team offers personal advice, custom setups, expert installation, operator training, and long-term tech help. This keeps things running smooth with high uptime.

Contact XINBO, a leading china cz purlin roll forming machine factory specializing in high-performance roll forming solutions. Our expert team is ready to discuss your needs, provide tailored configurations, and support your operations with installation and ongoing technical expertise. Reach out now to explore how XINBO can optimize your production line—let’s build stronger structures together!

Posts kuhusiana

Ubora mzuri

XinBo mashine kufanya CO. LTD ni mtengenezaji wa kitaalamu na nje katika roll kuunda mashine,

Tazama zaidi→

Kihispania

Kihispania Urusi

Urusi