Bending Lip Profile Roll Forming Machine for Steel Support of Canvas Curtains

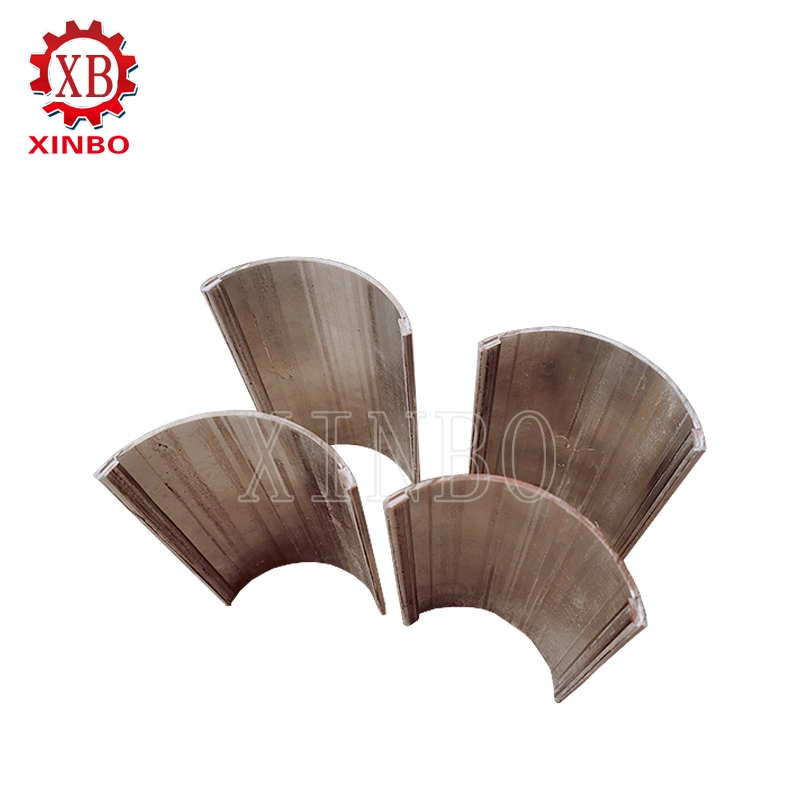

In certain metal shaping tasks, the Bending Lip Profile Roll kuunda mashine creates exact curved steel shapes with built-in edge lips. These shapes act as key steel support for canvas curtains. The bending lip setup forms a strong edge. It holds and pulls canvas cloth firmly. The curved or half-round form gives build strength over large areas.

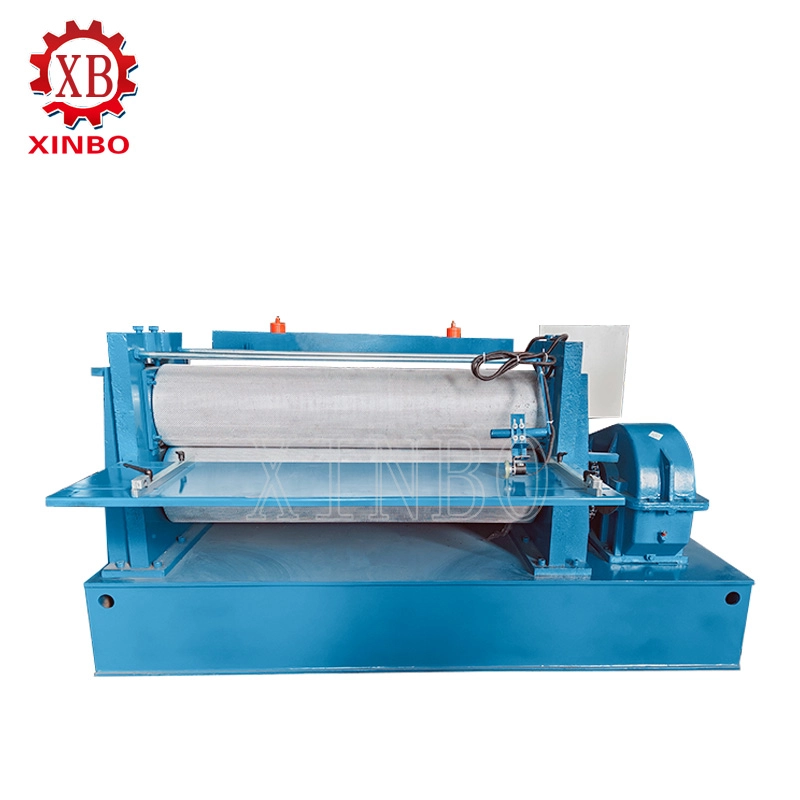

This solid tool mixes standard roll forming with added curving features. It makes steady, tough arched lip profile steel supports. They fit hard industrial curtain setups.

What is a Bending Lip Profile Roll Forming Machine?

A Bending Lip Profile Roll Forming Machine is a focused cold-roll forming tool. It is made to create lipped steel shapes. These shapes get steady round curving to reach bent forms. The tool slowly turns flat steel roll into a base path or half-tube shape. It adds inner or outer lips on the edges for extra strength. Then it curves the whole shape into exact bends or half-circles.

This combined method works well for building steel support for canvas curtains with bending lip profile parts. The lips stop canvas slide. They spread pull evenly. The bend makes even load move. It adds visual fit in uses like work dividers, farm covers, and short walls.

Common details include:

- Material thickness range: 0.8–2.0 mm (galvanized or cold-rolled steel)

- Profile width: 50–150 mm (adjustable)

- Arc radius: Customizable from 500 mm upward

- Line speed: 8–15 m/min

- Stations: 14–22 forming stations plus dedicated bending unit

The setup uses tough alloy steel rollers. It adds PLC auto control for steady exactness.

How Does a Bending Lip Profile Roll Forming Machine Work?

The Bending Lip Profile Roll Forming Machine uses step-by-step cold change via line-up roller spots. It keeps material strain low. And it gives fine surface look.

Core Working Principles

The flow starts with uncoiling and evening the steel strip. Then it goes into step roller spots. These form the base shape and lips. Next comes a special curving area. It adds steady round push to make the bend. This slow way stops breaks, folds, or twists. Such issues matter when shaping thicker sizes for build steel support for canvas curtains.

The curving part often adds changeable roller pairs. Or it uses push-aided tools. These lead the pre-shaped lipped form through a bent route. They keep even lip size. And they stop side fall.

Detailed Process Steps

- Decoiling and Feeding— Coil is loaded onto a powered decoiler with tension control; strip is leveled to remove coil set.

- Lip Formation— Dedicated edge-crimping rollers fold the strip edges inward (typically 10–30 mm lips) using grooved contours for sharp, consistent bends.

- Base Profile Shaping— Intermediate stations form the main channel or semi-circular section.

- Integrated Bending— The profile enters the bending unit where adjustable rollers impose progressive curvature while supporting the lips to avoid deformation.

- Final Calibration— Straightening rollers correct any springback or twist.

- Hydraulic Shearing— Profiles are cut to precise lengths (often 2–6 m for curtain supports).

- Output Collection— Finished arched lip profile pieces exit via runout table.

PLC link makes smooth shifts between spots. Sensors watch strip line and pace.

Main Parts of a Bending Lip Profile Roll Forming Machine

Strong-output Bending Lip Profile Roll Forming Machine setups have firm, exact-made parts.

Essential Components

- ya Decoiler— Hydraulic or manual, with coil loading capacity up to 5–10 tons.

- Feeding & Leveling Unit— Multi-roll straightener to eliminate curvature and ensure flat entry.

- Roll Forming Stations— 14–22 stands with chrome-plated, heat-treated rollers; each station incrementally advances the shape.

- Lip Crimping Tools— Specialized grooved rollers for precise edge folding.

- Bending Unit— Core differentiator; often hydraulic with adjustable top/bottom rollers for radius control.

- Hydraulic System— Powers cutting, bending pressure, and sometimes decoiler.

- PLC Control Cabinet— Touchscreen interface for speed, length, radius, and batch programming.

- Post-Cut Shear & Runout Table— Flying or stop-cut shear for clean ends.

Extra choices add line punching for fit holes. They add oil setups to lengthen roller life.

Workflow of the Bending Lip Profile Roll Forming Machine

The flow puts focus on steady work, exactness, and low stop time.

- Upakiaji wa vifaa— Position galvanized steel coil on decoiler.

- Initial Preparation— Strip feeds through leveler and entry guide.

- Progressive Forming— Roll stations shape base and form lips.

- Curvature Application— Profile enters bending section for arc formation.

- Final Calibration— Straightening rollers remove residual stresses.

- Cutting & Discharge— Automatic shear cuts to length; pieces collect on table.

This ongoing flow method allows large yield of even steel support for canvas curtains. It keeps steady lip sizes and bend form.

Applications of Bending Lip Profile Roll Forming Machine

The main use is in creating steel support for canvas curtains for:

- Industrial facilities for flexible partitioning and dust/weld spark containment

- Agricultural buildings for ventilation curtains and crop protection

- Warehouses and workshops requiring retractable barriers

- Temporary enclosures and event structures

The bending lip profile boosts canvas hold safety. The bent form spreads wind/snow loads well over areas up to some meters.

Advantages of Using a Bending Lip Profile Roll Forming Machine

This tool gives plain gains for makers of bent lipped shapes.

Faida muhimu

- Superior Precision— Incremental forming achieves tight tolerances on lip height (±0.2 mm) and radius consistency.

- Uhifadhi wa vifaa— Near-zero scrap compared to press-brake or weld-fabricated alternatives.

- High Throughput— Continuous operation supports medium-to-high volume production.

- Enhanced Strength— Cold work-hardening increases yield strength; lips add torsional rigidity ideal for canvas tensioning.

- Kubadilika— Quick tooling changes or adjustments accommodate different radii, lip sizes, and thicknesses.

- Surface Quality— Minimal scratching or marking preserves galvanized coating integrity.

- Ufanisi wa Gharama— Reduced labor, energy, and secondary operations lower overall manufacturing costs.

These traits make the Bending Lip Profile Roll Forming Machine a top pick for steady, good arched lip profile creation.

Maswali ya kawaida

What steel grades perform best in a Bending Lip Profile Roll Forming Machine?

Galvanized steel (Q235, SGCC) and cold-rolled mild steel (0.8–2.0 mm) are most common, offering good formability and corrosion resistance for outdoor canvas supports.

How is the bending radius adjusted during production?

Through the PLC interface, operators adjust the bending unit’s roller positions (often hydraulic) to set the desired arc radius with high repeatability.

Can the machine handle variable lip heights or asymmetrical profiles?

Yes, with modular or adjustable crimping rollers, lip dimensions can be varied; custom tooling supports specialized designs.

What preventive maintenance extends machine life?

Daily roller lubrication, weekly alignment checks, monthly hydraulic oil inspection, and quarterly bearing/gripper servicing maintain accuracy and reduce downtime.

Is post-forming heat treatment required?

No—cold forming preserves material properties; annealing is unnecessary for most canvas support applications.

Contact XINBO Today for Your Custom Roll Forming Solution

For making lasting, exact-bent steel support for canvas curtains with forward roll forming tech, the Bending Lip Profile Roll Forming Machine gives a smooth and solid fix. ya XINBO focuses on planning and building fitted roll forming tools matched to clear shape details and yield needs. Contact XINBO today to go over task points, get pro tech advice, and see how their strong tools can better the making flow. Reach out now to begin building stronger holds for canvas curtain setups.

Posts kuhusiana

-

Best Rain Gutter Roll Forming Machine for Aluminum and Steel Gutters

-

Best Roll Shutter Door Forming Machine: Unmatched Precision and Efficiency Explained

-

How a Metal Signboard Cladding Panel Roll Former Transforms Modern Storefront Design

-

China Sheet Metal Embossing Machine Company: What to Look for Before Buying

Ubora mzuri

XinBo mashine kufanya CO. LTD ni mtengenezaji wa kitaalamu na nje katika roll kuunda mashine,

Tazama zaidi→

Kihispania

Kihispania Urusi

Urusi