Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

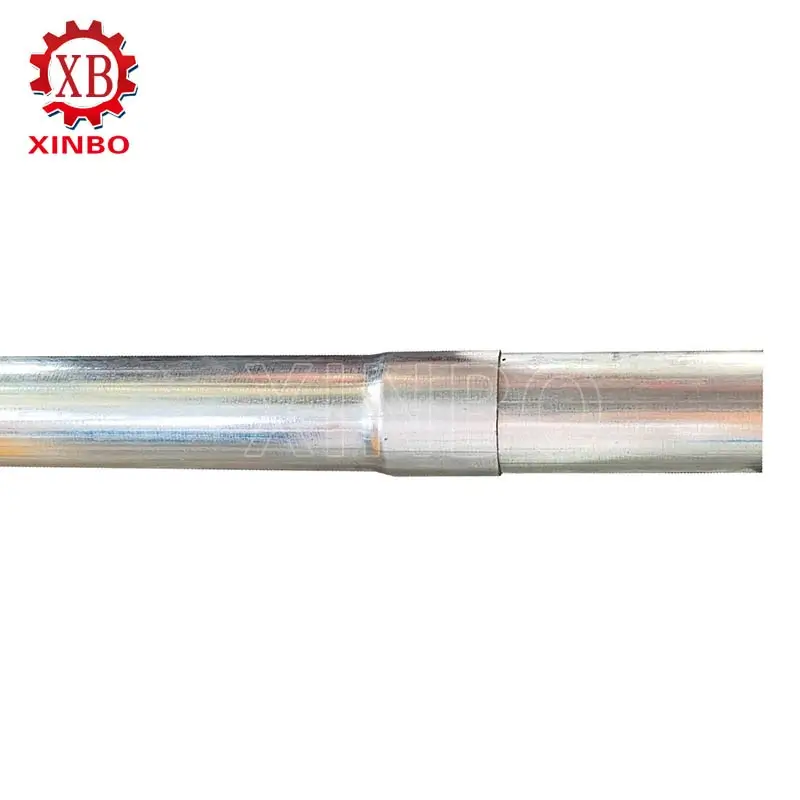

VIEW MORE→A welded pipe roll forming machine is a unique tool. It shapes metal strips or sheets into round, square, or rectangular tubes. This happens through ongoing rolling and welding steps. The machine uses welding methods like high-frequency induction (HF) welding or TIG (Tungsten Inert Gas) welding. These join the edges to make steady tubes. The tubes are suitable for many industrial uses. They are mainly made from stainless steel or carbon steel.

The welded pipe roll forming machine has many modern features. These make it essential in industrial production. Its process includes unwinding, flattening, hydraulic hole-punching, rolling, welding, and cutting. The machine parts include a hydraulic unwinder, flattening device, hydraulic punching station, rolling unit, hydraulic cutting saw, output table, hydraulic pump, and electrical control box.

Technical details show its efficiency:

Material thickness: 3.0 mm

Input width: ~416 mm

Production speed: 2–5 m/min

Forming stations: 17

Cutting accuracy: Length ±1.0 mm

These machines use HF welding for fast production. They use TIG welding for stainless steel tubes with argon gas protection for strong welds. They can make round, square, or rectangular tubes from materials like stainless steel and carbon steel.

Welded pipe roll forming machines are used in many fields:

Construction: They make structural parts like railings.

Oil and Gas: They create pipelines and fuel lines.

Automotive: They produce exhaust tubes and frames.

Furniture Making: They form tubing for furniture.

Decorative Uses: They craft handrails and outdoor decorations.

Specific uses include making round tubes for decorative or structural needs. Square tubes are used for railing spacers.

The welded pipe roll forming machine offers many advantages:

High Production Speed: Steady production allows quick output for large-scale work.

Cost Savings: It lowers costs compared to seamless tubes.

Shape Variety: It can create different tube shapes and sizes.

Strong Structure: Welded tubes provide great strength and durability.

Less Extra Work: Combined processes reduce downstream costs.

Material and Labor Savings: It uses metal efficiently and needs less labor.

A tube expander machine is a device. It widens tube ends to secure them tightly in tubes or headers. It achieves exact widening through mechanical or powered methods. This ensures a sealed connection.

The main job of the tube expander machine is to create tight mechanical bonds between tubes:

Working Principle: It uses rollers or other tools for widening.

Types:

Manual expanders for small tasks.

Powered expanders (hydraulic, pneumatic, electric) for industrial uses.

Design Features:

Self-centering tools for even widening.

Adjustable rollers for various tube sizes.

Suitable materials include soft copper, aluminum, stainless steel, and carbon steel. Tube sizes range from small (e.g., 1/4 inch) to large tubes.

Tube expander machines provide several benefits:

They remove the need for extra fittings by widening tubes directly.

They simplify setup processes while ensuring strong seals to prevent leaks.

They lower operating costs compared to welding methods.

Precision-designed tools ensure long-lasting use.

The welded pipe roll forming machine and tube expander machine work together in the tube production process.

The roll forming machine creates tubes from metal strips. These tubes are key parts in construction or industrial equipment.

Tubes made by the roll forming machine are sent to facilities. These facilities need assembly tools like heat exchangers.

The tube expander secures these tubes in place quickly.

Together, these machines improve workflows from production to use. They boost efficiency in construction, energy, automotive, and other fields.

Their combined effect drives automation in manufacturing. It also cuts costs at production and upkeep stages.

The welded pipe roll forming machine and tube expander machine are vital in industrial production. They offer smooth integration of making and assembling processes. The roll forming machine is great at shaping metal strips into tubes through steady rolling and welding. The tube expander ensures accuracy in securing these tubes during assembly or upkeep.

The welded pipe roll forming machine supports automation and growth in tube production. Its high output speed allows large-scale production. This meets varied market needs in fields like construction, automotive, and oil and gas. The machine cuts production costs by reducing material waste and labor needs. It is a budget-friendly solution for making tubes with strong structure.

The tube expander machine improves assembly efficiency. It simplifies securing tubes in tubes or headers. This removes the need for extra fittings or welding. It lowers operating costs. The tight seals prevent leaks. This ensures reliability in heat exchangers, boilers, and other equipment. Its precise design also improves heat transfer and extends equipment life.

Together, these machines streamline workflows from tube production to use. The roll forming machine makes tubes. These are later secured by the tube expander in various applications. This creates an efficient process. It boosts overall productivity. This teamwork supports fields like construction, energy, automotive, and equipment manufacturing. It reduces costs at both production and upkeep stages.

Xinbo leads in providing modern solutions for roll forming machines since 2014. Its welded pipe roll forming machines are tailored to customer needs. They offer flexibility in making round, square, or rectangular tubes from stainless steel or carbon steel. These machines include advanced features like hydraulic unwinders, flattening devices, hydraulic punching stations, rolling mechanisms, automatic cutting systems, and computer control boxes.

Besides making welded pipe roll forming machines, Xinbo offers tube expander machines. These ensure precise tube widening. The tools come in manual and powered versions (hydraulic, pneumatic, or electric). They suit different work scales. Their adjustable rollers handle various tube sizes. They maintain even widening for strong mechanical bonds.

Xinbo’s focus on quality shows in its adherence to Euro standards like CE certification. Their products are sold worldwide. They serve markets in Europe, the Middle East, Africa, America, South America, and beyond.

What materials can be used with a welded pipe roll forming machine?

Welded pipe roll forming machines can handle materials like stainless steel and carbon steel, among others.

What industries benefit from using a tube expander machine?

Fields like heat exchanger production, boiler upkeep, condensers, and cooling systems gain greatly from tube expanders. They ensure strong seals and efficient heat transfer.

How do these two machines complement each other?

The welded pipe roll forming machine makes tubes efficiently for various uses. The tube expander secures these tubes during assembly or upkeep. This ensures reliability and performance in their final use.

Are Xinbo’s machines customizable?

Yes, Xinbo designs its machines based on customer needs. This meets specific operational requirements effectively.

What are the advantages of using these machines together?

Using both machines together streamlines workflows from production to use. This combination cuts costs at both stages. It also boosts efficiency across fields like construction and energy.

For more details or inquiries about Xinbo’swelded pipe roll forming machine and tube expander machines, contact their team now.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→