Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→In today’s construction and roofing business, a good rain gutter roll forming machine has become necessary equipment. It helps make strong, smooth, and nice-looking gutters right at the job site or inside factories. People also call it a gutter cold roll forming machine. This smart tool turns flat metal coils into exact gutter shapes through a steady cold-bending method. Whether someone looks for the best rain gutter roll forming machine or trusted gutter roll forming machine manufacturers, knowing how these machines operate and what makes a good one matters a lot for a smart purchase.

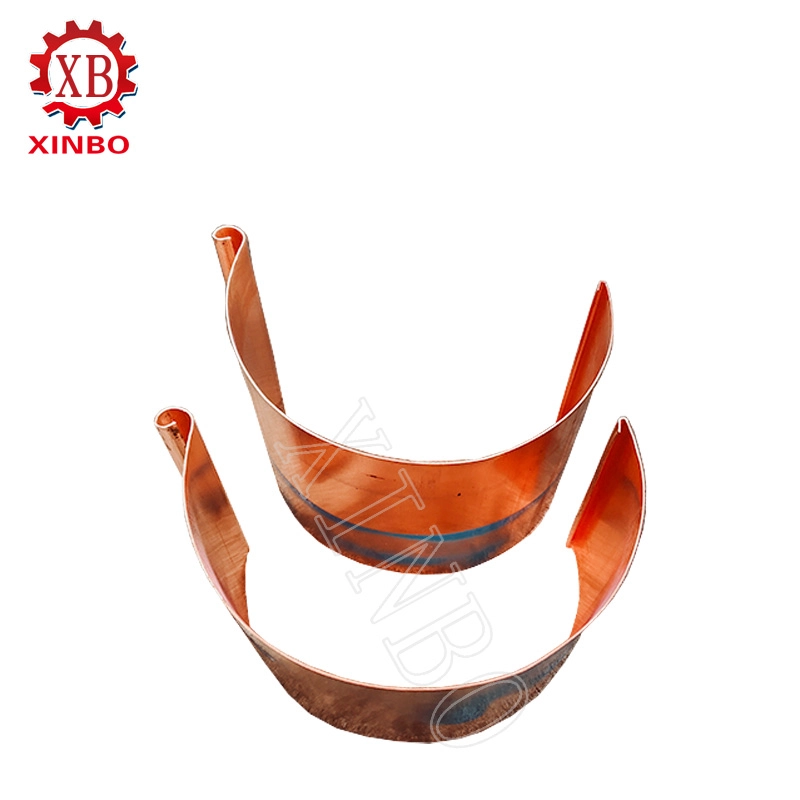

A rain gutter roll forming machine is special equipment built only for making different gutter shapes. These include K-style, half-round, and special designs. The whole job begins with a decoiler. It feeds galvanized steel, pre-painted steel, aluminum, or copper coils into the machine.

The metal first goes through many carefully made roll stations. Usually there are 18 to 24 stations, depending on how complex the shape is. Each station slowly bends the metal without any heat. That is why people call it a gutter cold roll forming machine. This cold way keeps the protective zinc or paint layer safe. As a result, gutters resist rust much longer and last many years.

When the shaping finishes, a built-in hydraulic shearing unit cuts the long gutter to any needed length. The cut is always exact. Today’s water gutter roll forming machines come with PLC touch-screen controls. Operators can easily set the length, number of pieces, and batch jobs. Very little hand work is required.

Buying a top-quality gutter roll forming machine for sale brings clear benefits. These directly help earn more money and keep product quality high:

Seamless gutters without weak spots or leaks

Making gutters at the job site lowers shipping damage and costs

One single machine can create several gutter profiles just by switching tooling

Fast production speed: 15–30 meters per minute

Almost no wasted material because computer control is very accurate

Even wall thickness and perfect shape every time

These points explain why contractors and factories all over the world now prefer modern custom rain gutter roll forming machines instead of old brake bending or extrusion ways.

A strong hydraulic decoiler with auto tension control feeds material smoothly. It works well even with thick 0.5–0.8 mm steel coils running fast.

A seven-roller or nine-roller leveler takes away coil curve and inside stress. This makes sure the material enters the forming stations completely flat.

Every roller uses Cr12MoV or SKD11 steel. Workers machine them on CNC, heat-treat them in vacuum to HRC 58–62, and add chrome or nitride coating. This gives very long life. Shafts are solid 45# steel or 40Cr with 70–80 mm diameter. They never bend under heavy loads.

Most good gutter roll forming machine manufacturers now give both choices. Pre-cutting stops end flare. Post-cutting gives cleaner edges on painted coils.

Siemens, Panasonic, or Delta PLC with 10–15 inch touch screen works in many languages. It measures length automatically (±1 mm accuracy) and allows remote help through Wi-Fi.

Pneumatic or hydraulic tables expand and hold long gutters. This stops them from dropping or getting scratches while the line runs fast.

The best rain gutter roll forming machine can handle:

Pre-painted galvanized steel (PPGI)

Galvalume (Aluzinc)

Aluminum (0.4–1.0 mm)

Copper and stainless steel (with special rollers)

Thickness range: 0.3–0.8 mm (common for gutters)

Material hardness must stay below HRB 90. This protects rollers and keeps coatings perfect.

Some high-level models let workers switch from K-style to half-round profiles in less than 30 minutes. They just use cassette tooling. This helps factories that serve different areas.

Several china gutter roll forming machine companies make smart double-layer machines. These can produce both 5-inch and 6-inch gutters on one frame. Space in the workshop is used better.

Full protective covers with safety switches

Emergency stop buttons on every part

Automatic lubrication system for rollers and bearings

Fault alarm and self-check screen

Such features cut downtime greatly and keep workers safe.

Decide which profiles and sizes are needed (5″, 6″, 7″, half-round, fascia, etc.)

Check roller material and shaft diameter—never take GCr15 without proper heat treatment

Make sure the PLC brand and servo motor are good (Yaskawa, Mitsubishi, or Panasonic are best)

Ask to see real running videos at full speed with the buyer’s own material

Check warranty time and after-sales support

A trusted china gutter roll forming machine manufacturer will happily offer installation at the factory, training, and lifelong technical help.

Clean metal chips from rollers every day

Check hydraulic oil level and quality each month

Lubricate bearings and chains once a week

Calibrate the length sensor every 3 months

Look at roller surfaces for scratches or buildup

Simple daily care lets heavily used machines stay accurate for 15–20 years.

The industry is quickly moving toward:

Fully servo-driven systems for better precision

Connection with mobile apps so owners can watch production from anywhere

Automatic profile change without hand work on cassettes

AI cameras that spot defects right away

Eco-friendly powder-coated frames instead of normal paint

These new ideas will make work faster and need fewer workers.

Q: What is the difference between a gutter roll forming machine and a downspout roll forming machine?

A: A gutter machine forms the horizontal rainwater collection channel, while a downspout machine produces the vertical pipes. Many manufacturers buy them as a complete set.

Q: Can one machine produce both K-style and half-round gutters?

A: Yes, with quick-change cassette tooling or dual tooling design, switching takes 20–40 minutes.

Q: How long does it take to learn operating the machine?

A: With professional training, a new operator can master basic operation in 2–3 days. Full proficiency usually takes 2–4 weeks.

Q: Is on-site production really better than factory-made sectional gutters?

A: Seamless on-site gutters have no leaks at joints, custom lengths with zero waste, and immediate installation—preferred by 90% of premium contractors.

Q: What is the typical power requirement?

A: 11–18.5 kW total (main motor 7.5–11 kW + hydraulic station 5.5 kW), 380V 50Hz 3-phase standard.

Q: Can the machine run copper or stainless steel?

A: Yes, but requires dedicated polished rollers and adjusted forming speed to prevent scratching.

If a proven, high-precision gutter cold roll forming machine with more than 20 years of experience and installations all over the world is needed, contact the skilled team at XINBO today.

Company: XINBO

Specialization: High-end roll forming solutions for gutter, downspout, roofing, and highway guardrail

Service:

· Free profile drawing design

· Complete factory layout planning

· Lifetime technical support

Contact: Send required gutter profile drawing or samples for a customized quotation and live demonstration video within 24 hours.

Take the first step toward seamless, profitable gutter production—reach out to XINBO now and learn why contractors worldwide trust these machines for their toughest projects.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→