How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

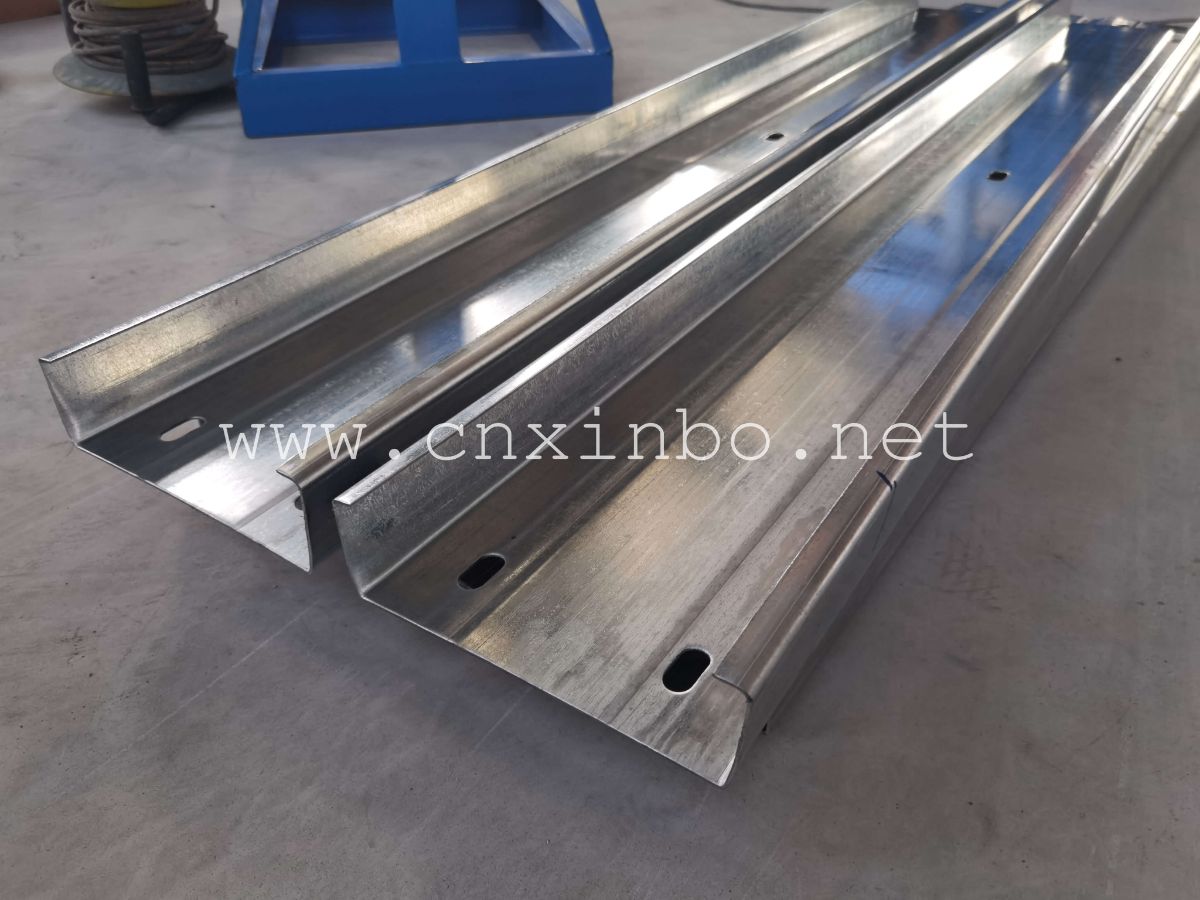

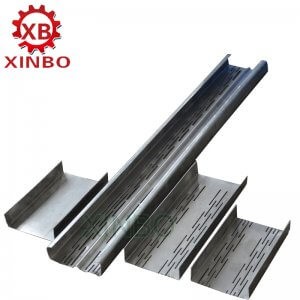

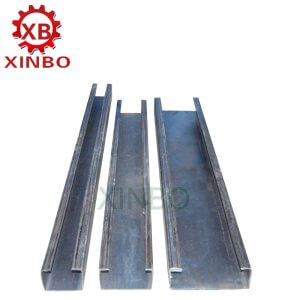

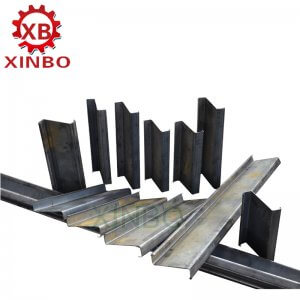

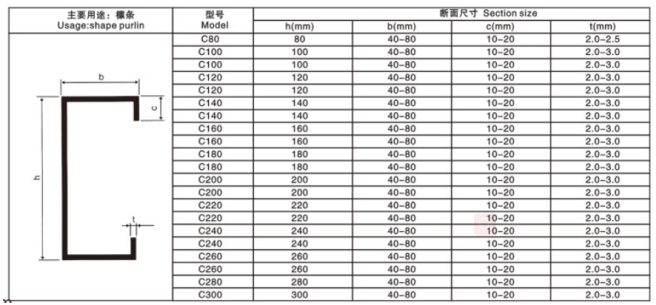

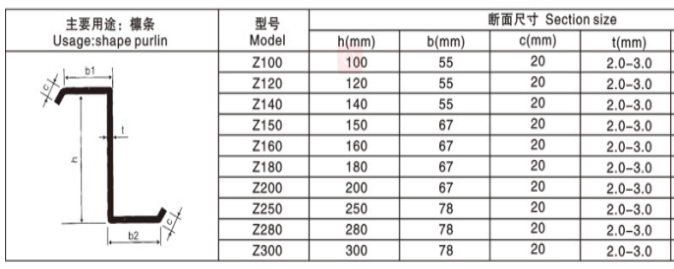

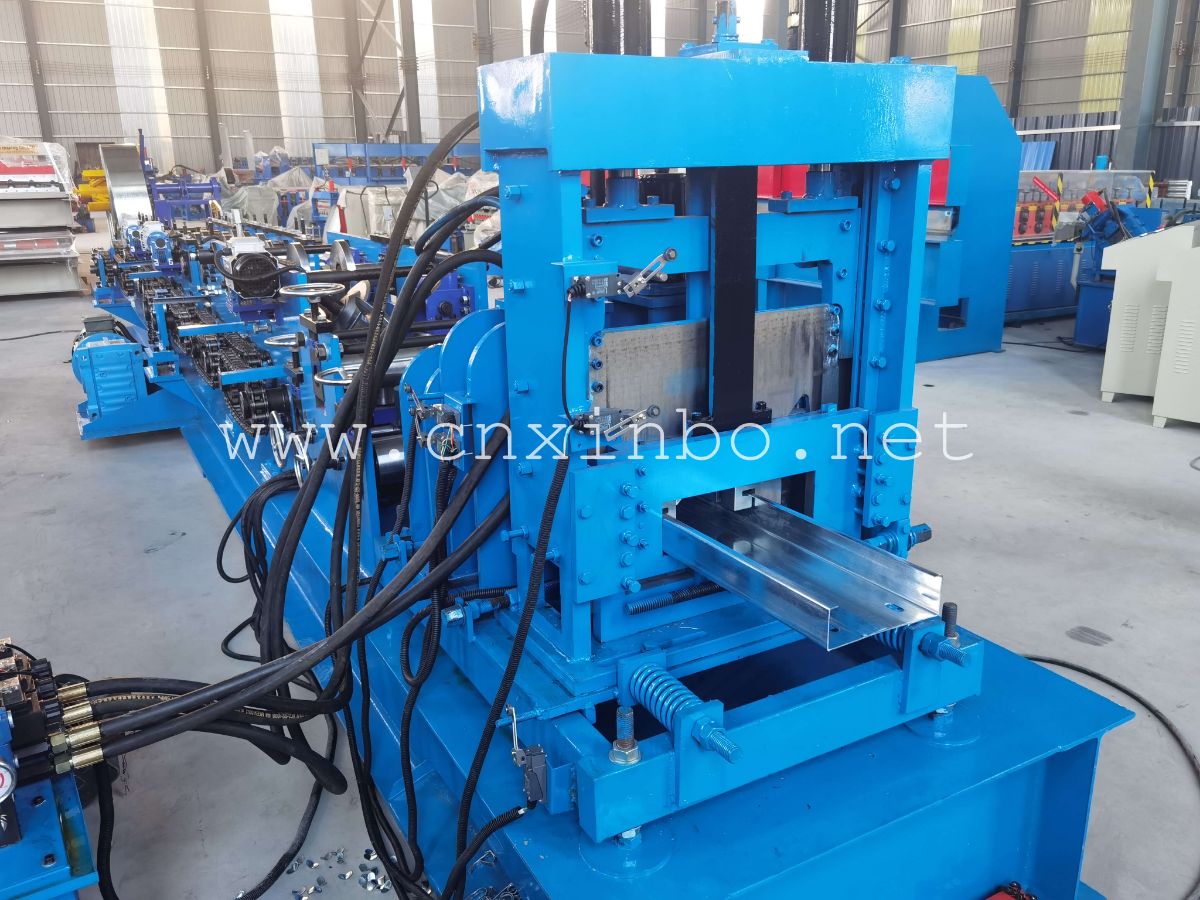

This automatic C/Z purlin interchangeable machine uses one equipment to be possible to produce the C/Z purlin for different sizes.

When the size changes, it is no need to replace the forming rollers. The production process selects the automatic control method, which helps to realizes auto-running, cutting, and punching holes automatically.

|

Suitable to Process |

Galvanized steel strip/black steel strip |

|

Width of raw material |

customized |

|

Rollers |

GCr15 |

|

Dimensions |

About 8500*1300*1400mm |

|

Power |

22+5.5kw |

|

Thickness of sheet |

1.5–3.0mm as usual; customized |

|

Material of cutting blade |

Cr12 |

|

Diameter of the roller |

customized |

|

Voltage |

380V, 50Hz, 3 phrases; customized |

|

weight |

About 7.0T |

|

Productivity |

0—-15m/min |

|

Control system |

Automatically controlled by computer |

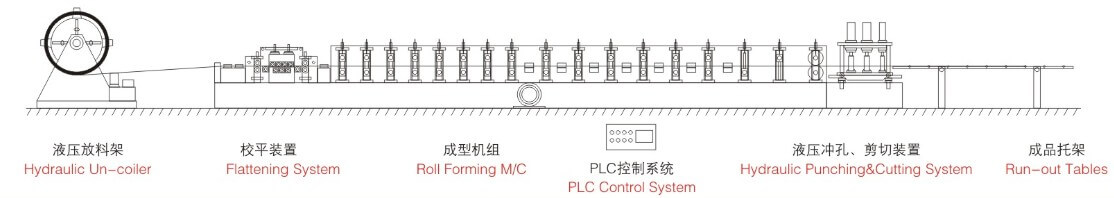

The C/Z purlin machine consists of the guider, leveler, hydraulic hole punch devices, hydraulic cutting device, fast roller exchange forming machine, the electric controlled system and hydraulic system etc.

coil materuial Bearing part(from 3T to 5T)

coil materuial Bearing part(from 3T to 5T)

Material inputting and flatter part.

Material inputting and flatter part.

Forming parts and automatic changing sizes part.

Automatic cutting head.

Computer part