Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→In today’s building and rainwater management world, downpipe roll forming machines are must-have tools. They make strong drainage parts. These systems guide rainwater away from buildings safely. This stops damage and helps the environment. With unpredictable rain due to climate change, solid drainage systems are more needed. Automatic Downpipe roll forming machines give a fast, automated answer. They meet demands for homes, businesses, and factories.

An Automatic Downpipe Roll Forming Machine is a special tool. It makes downpipes, also called downspouts or rainwater pipes. It uses a continuous metal forming process. The machine takes metal coils, like galvanized steel, aluminum, or copper. It turns them into hollow shapes for moving water from roofs to ground drains. This cold-forming process happens at room temperature. It keeps the metal strong and saves energy.

The method ensures precise, repeatable results for big production. Automated models use programmable logic controllers (PLCs). These handle feeding, shaping, and cutting. They’re perfect for large-scale work.

A CNC downpipe roll forming machine runs smoothly. It turns a flat metal coil into a finished downpipe. The process starts with a decoiler. This uncoils the raw material. The metal strip then moves through roller stations. These bend it into the desired shape slowly. The main technique is roll forming. It’s a cold method that shapes metal without changing its thickness much.

Once the shape—round or square—is ready, it goes to the cutting station. Hydraulic shears or flying saws cut it to set lengths. Advanced models use CNC systems. These keep sizes accurate throughout.

A downpipe roll forming machine has several key parts. They work together for smooth, high-quality results. These include:

Decoiler: Feeds the metal coil.

Feeding System: Lines up and straightens the material.

Forming Rollers: Hardened steel rollers, set in 20–26 stations.

Cutting Mechanism: Uses hydraulic or flying saws.

Control System: PLC or CNC-based touch screens.

Drive System: Powered by servo motors.

Support Frames & Safety Guards: Keep the machine strong and safe.

Extra parts like punching units or seam lockers may be added for custom needs.

The workflow is a straight, automated process built for speed. It starts by loading the coil onto the decoiler manually. The strip moves through feeding platforms to roller stations. These shape it step by step. Midway steps like punching or embossing can be added based on the project.

After shaping, an automatic cutting system slices the profile to set lengths. Flying cut technology keeps production moving. The machine has manual mode for setup and automatic mode for production. Speeds adjust via the control panel.

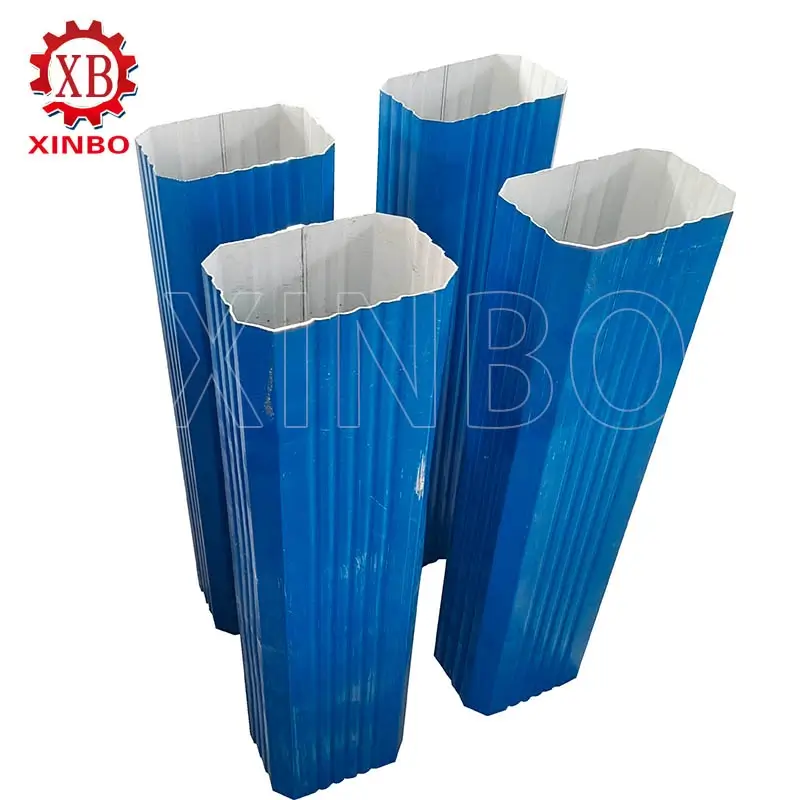

Metal downpipes come in two main types: square (or rectangular) and round. Each fits different building and function needs.

Square Downpipes: These have a neat, modern look. They sit flat against walls. They’re popular in commercial buildings where space matters.

Round Downpipes: These come in sizes for any use, from homes to factories. Their round shape allows smooth water flow and less noise.

Both can be made with dedicated or hybrid roll forming machines that switch between shapes.

Downpipes are key in homes. They move rainwater away from foundations. This prevents basement flooding. Machines made for smaller profiles create parts for single-family homes or apartments efficiently.

In big buildings like malls or factories, square downpipes are preferred. They hold more water and mount easily on walls. Machines for these have higher output power.

City stormwater drainage systems use these machines too. Custom setups make heavy-duty profiles for public works projects.

Downpipe roll forming machines offer many perks for cost-effective rainwater management:

Fast production (up to 15 m/min).

Little waste created.

Strong durability from cold-forming.

Steady quality through automation.

Works with different metals.

Eco-friendly with low energy use.

These make them better than manual methods like welding.

Customization is a big feature. Roller stations can change for different sizes or shapes based on project needs.

Machines can add punching for bracket holes or embossing for designs. This boosts function and style of the final product.

These machines work with galvanized steel, aluminum, and copper. This makes them flexible for industries with different corrosion resistance needs.

Production is efficient thanks to automation and smart design. Flying cut systems keep work flowing. Sensors ensure precise alignment. Scrap rates stay under 5%. This maximizes material use.

Good care extends machine life. Daily cleaning stops debris on rollers. Weekly lubrication keeps parts moving smoothly. Operator training ensures safe use every time.

Future downpipe roll forming machines will see more automation. AI will predict issues to boost efficiency. IoT devices will allow remote checks. Sustainable materials will become common. Hybrid models that make multiple profiles will simplify work across industries.

XinBo started in 2014, is a 100% manufacturer. It guarantees high-quality machines with new technology. This comes from skilled engineers, technicians, and workers. Roll forming machines are designed and built to meet customer requests.

Whether square or round profiles—or both—are needed, XinBo offers custom solutions. The design team builds machines to match specific needs. With exports to Europe, the Middle East, Africa, America, and South America, XinBo meets CE standards. Expect reliable performance with global expertise.

From design to installation and after-sales service, XinBo provides top products and full support, including “product designing, assembling, installation, and after-sales service” as a one-stop solution.Contact XinBo today for your machines.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→