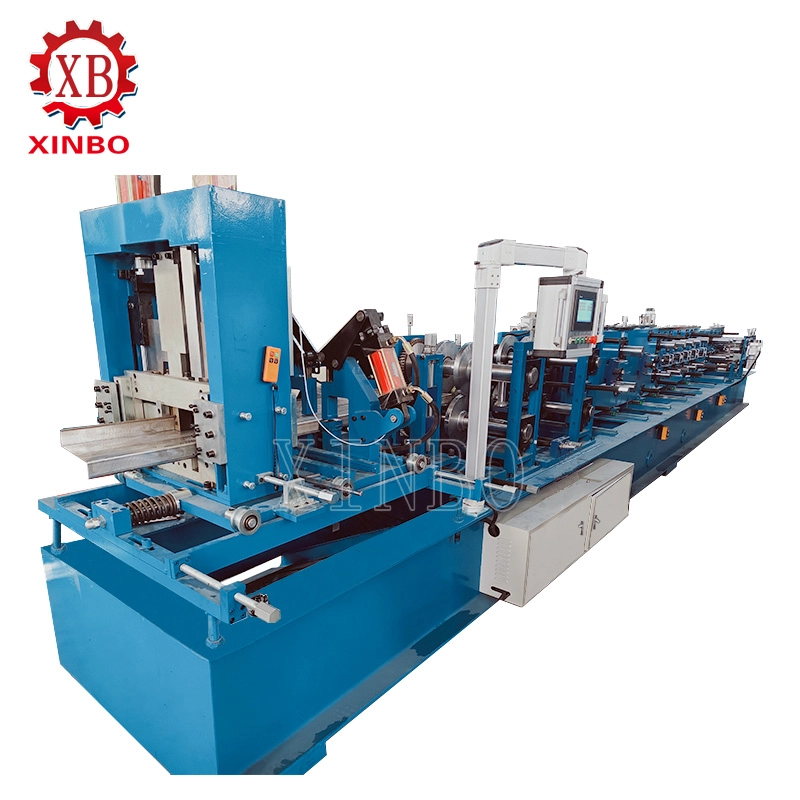

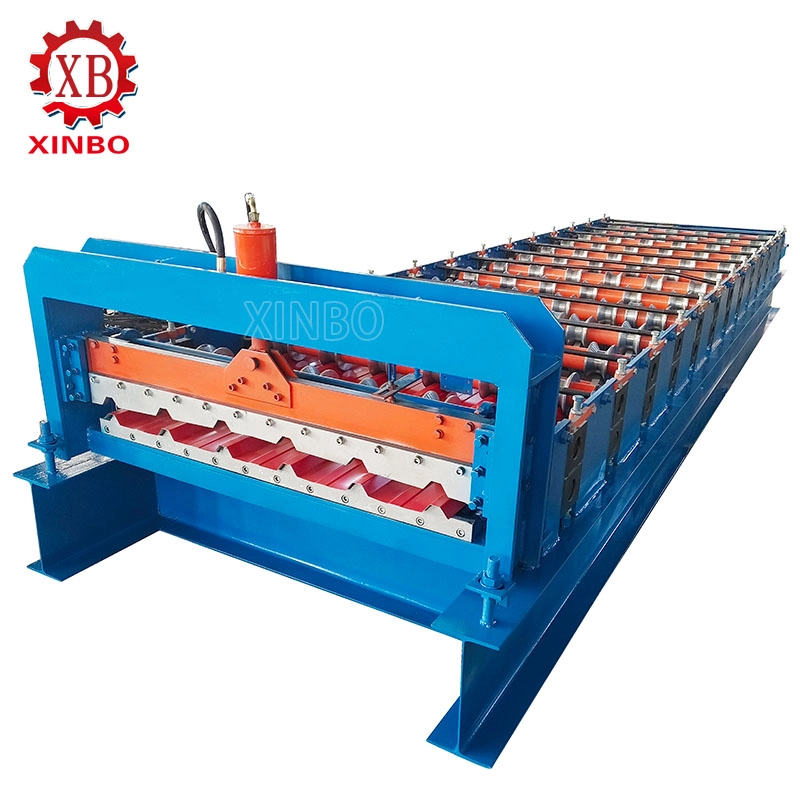

Automatic Trapezoidal Roof Roll Forming Machine for Multi-Rib Roofing Panels

The Automatic Trapezoidal Roof Roll Forming Machine for Multi-Rib Roofing Panels serves as an efficient production tool. It makes strong metal roofing sheets with the classic multi-rib trapezoidal shape. The machine changes flat metal coils into ready panels. These panels offer solid structure, good water runoff, and a neat modern style. People use them a lot in factories, stores, farms, and homes for roofing.

Why Trapezoidal Multi-Rib Profiles Remain a Top Choice

The multi-rib trapezoidal shape brings real benefits in function and looks. It fits tough roofing jobs well.

-

Increased Panel Stiffness — The raised ribs make deep channels. These channels boost bending resistance a lot. So panels can cover longer distances between supports.

-

Superior Rainwater Drainage — Angled trapezoid ribs create good channels. Water flows off the roof fast. This cuts down on standing water, even when the roof slope is small.

-

Balanced Strength-to-Weight Performance — Smart rib design lets you use thinner metal. Panels still hold heavy loads well. The whole roof weighs less as a result.

-

Attractive and Professional Finish — Even, strong rib lines create a clean, up-to-date appearance. It works great for factories, warehouses, shopping centers, and new homes.

Common materials include PPGI (pre-painted galvanized steel), GI, galvalume/aluzinc-coated steel, and aluminum coils. Thickness runs from 0.3–0.8 mm. Coil widths go from 914 mm to 1250 mm. After forming, the effective coverage width comes to about 1000 mm.

Real-World Benefits for Roofing Contractors and Building Owners

-

Good resistance to wind lift and big snow weight.

-

You need fewer purlins because panels span better.

-

The surface stays clean and needs little care over time.

Main Components of a High-Performance Trapezoidal Roof Roll Forming Machine

A solid trapezoidal roof panel roll forming machine combines well-made parts. They team up to give steady, quick output.

Coil Handling and Entry

-

Decoiler — Strong unit (manual or hydraulic). It handles 5–10 ton coils. Unwinding stays smooth with controlled tension. This protects the coil edges.

Feeding and Guiding Section

-

Straightening rollers and side guides keep the strip lined up right. They stop any twist. Ribs form evenly right from the start.

Roll Forming Core

-

15–25 forming stations use high-grade alloy steel rollers. These rollers get surface-hardened and chrome-plated. They last long and leave no scratches on panels.

-

Roller shapes change step by step. They turn the flat strip into clear, even trapezoid rib patterns.

Cutting and Discharge

-

Hydraulic cutting system (fixed-position guillotine or flying shear) cuts panels cleanly. Lengths stay exact with little bend or damage.

-

An optional protective film applicator puts on a short-term layer while making panels.

Control and Structural Systems

-

Industrial PLC controller has a color touch-screen. It makes setting panel length, count, speed, and batches simple.

-

Heavy-duty hydraulic power pack and strong welded steel frame keep everything steady at top speed.

How the Machine Produces Multi-Rib Panels Step by Step

The whole process runs on automation. It repeats well every time.

-

Coil Loading — Place the coil on the decoiler. Feed the front edge into the machine.

-

Precise Alignment — The material goes through guides and levelers. This gives perfect entry.

-

Progressive Forming — Each station bends the strip a bit more. It builds the full multi-rib trapezoidal profile.

-

Accurate Shearing — The hydraulic cutter cuts panels to the set length.

-

Panel Exit — Finished sheets slide out to the run-out table. They wait for stacking or bundling.

Production speed depends on setup. It usually hits 10–60 meters per minute. Dimensions stay very consistent.

Advantages of Investing in a Durable Multi Rib Roofing Roll Forming Machine

Picking strong equipment improves quality and work flow clearly.

-

High Degree of Automation — PLC control with one button cuts down on hand work. One person can watch most jobs.

-

Consistent Panel Quality — Precise rollers and matched systems give even rib height, spacing, and edge look on every sheet.

-

Material Savings — Good forming cuts waste at the edges. It uses more of each coil.

-

High Throughput Capability — Quick cycles handle big orders. Quality stays the same.

Efficiency and Scalability Benefits

-

Quick changes between batch sizes.

-

Steady work through long shifts.

-

Simple fit with current coil lines.

FAQ

Which coil thicknesses work best on a trapezoidal roof panel roll forming machine?

Most machines do well with 0.3 mm to 0.8 mm coils. This range balances easy forming and strong final panels.

Can a trapezoid rib roofing roll forming machine manufacturer produce custom rib patterns?

Yes. Roller tooling allows custom designs. It changes rib heights, widths, spacings, and edge details to fit exact needs.

What output speeds are realistic for a high quality rib roofing roll forming machine?

Standard models run 10–30 m/min. Advanced ones with flying-cut systems go up to 60 m/min for top output.

How does a durable multi rib roofing roll forming machine ensure long-term dimensional accuracy?

Hardened, precision-ground rollers work with servo length control and PLC checks. They hold tight tolerances during long runs.

Why do many buyers choose china multi rib roofing roll forming machine manufacturers?

They provide good mixes of new tech, strong build, custom options, and solid after-sales help.

Upgrade Your Roofing Production with XINBO’s Automatic Trapezoidal Roof Roll Forming Machine

If you want to grow or improve capacity for top multi-rib roofing panels, the Automatic Trapezoidal Roof Roll Forming Machine for Multi-Rib Roofing Panels from XINBO offers precision, speed, and long life. As a specialized producer of advanced roll forming equipment, XINBO delivers machines made for actual factory use. It includes expert advice and custom choices. Contact XINBO today. Check specs, talk about coil types and panel needs, and see how this gear can boost your line in a solid, reliable way.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia