Automatic U-Shape Baffle Ceiling Machines: Features, Advantages, and Applications

Introduction to U-Shape Baffle Ceiling Machines

Defining the U-Shape Baffle Ceiling Machine

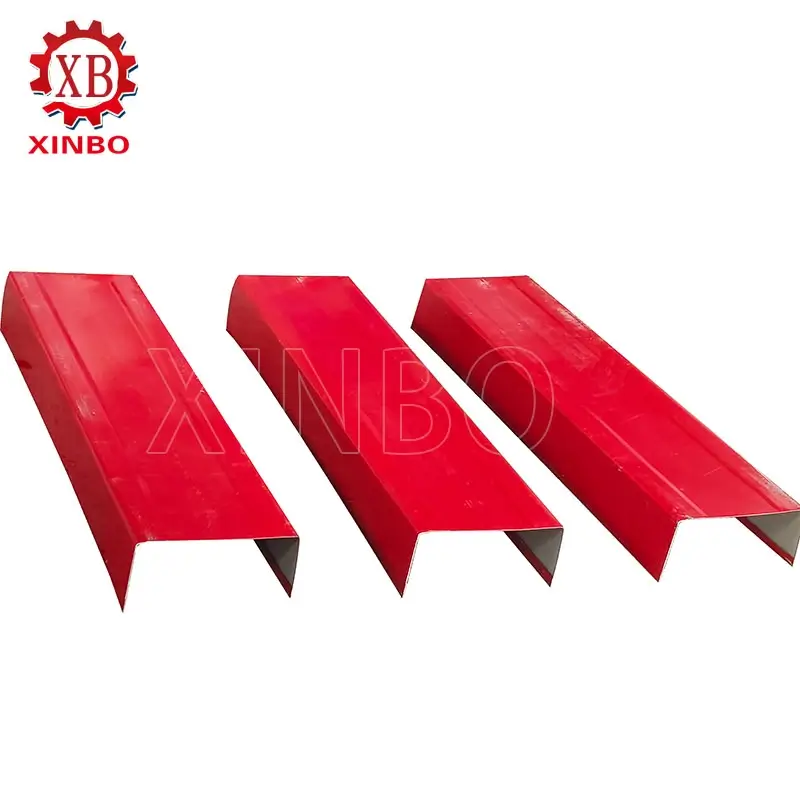

A u shape baffle ceiling machine is a device that transforms metal sheets into U-shaped baffles for ceiling systems. It employs a series of rollers to shape materials like aluminum or galvanized steel into precise U-profiles. The baffle ceiling machine is valued for producing sleek, acoustic-enhancing ceiling components. Its automated process ensures uniform output and high efficiency. Grasping the function of a metal baffle ceiling machine aids businesses in selecting equipment to streamline ceiling baffle production.

Importance in Modern Construction

The china u baffle machine plays a vital role in contemporary construction, creating baffles for stylish, functional ceilings. These baffles are used in commercial spaces to improve sound quality and aesthetics. The ability of a u baffle ceiling making machine to produce large quantities makes it essential for manufacturers serving expansive projects. Understanding its significance helps businesses align equipment choices with the demands of modern building designs.

Core Features of U-Shape Baffle Ceiling Machines

Advanced Automation Technology

A high-quality u shape baffle ceiling machine incorporates cutting-edge automation. It uses a PLC system to manage shaping and cutting, ensuring precise baffle dimensions. The wholesale u shape baffle ceiling machine minimizes manual intervention, enhancing production speed. Automation allows businesses to produce consistent, high-standard baffles efficiently, making a u baffle machine customized a top choice for meeting client expectations.

Robust Build and Material Versatility

A durable ceiling u baffle machine is constructed with resilient components, such as Cr12 rollers, for long-lasting performance. It processes materials like galvanized steel or aluminum, typically 0.3-1.0 mm thick. The low cost u baffle machine withstands heavy use while offering flexibility to create various baffle designs. This versatility is crucial for businesses using a u baffle machine wholesale to meet diverse project specifications.

Essential Components of a U-Shape Baffle Ceiling Machine

Metal Feeding and Alignment System

The feeding system in a u baffle machine includes a decoiler that unwinds metal coils and aligns them for processing. This system ensures smooth material flow, preventing disruptions. Accurate alignment is critical for a china ceiling system machine to produce flawless baffles. A reliable feeding system supports continuous production, making it a key feature of a u shape baffle ceiling machine manufacturers china.

Forming and Precision Cutting Mechanisms

The forming mechanism in a buy u baffle making machine uses rollers to mold metal into U-shaped baffles. The precision cutting system then trims baffles to exact lengths with clean edges. These components in a u baffle ceiling making machine work seamlessly to produce high-quality baffles with minimal waste, enabling businesses to meet large-scale project demands efficiently.

Power and Control Infrastructure

The power system in a buy baffle ceiling machine relies on hydraulics, driven by a gear wheel oil pump, to support forming and cutting. The PLC control infrastructure allows easy adjustments to settings like baffle size and speed. This makes the fair price u baffle machine user-friendly and efficient, ensuring a baffle machine supply meets production goals with accuracy.

How to Operate a U-Shape Baffle Ceiling Machine

Initial Setup and Calibration

Operating a u shape baffle ceiling machine begins with setting up the decoiler and loading a metal coil, typically 0.3-1.0 mm thick. Operators inspect the material for quality and calibrate the machine for the desired U-baffle profile. Proper calibration in a u baffle machine suppliers’ equipment ensures error-free production. This preparation is essential for businesses using a purchase u baffle machine to achieve consistent baffle quality.

Running and Troubleshooting

Running a wholesale u baffle machine is straightforward with its PLC interface. Operators input parameters like length and speed, then initiate production. The china baffle machine operates automatically, but workers monitor for issues like material jams. Quick troubleshooting keeps a baffle machine supplier’s equipment running smoothly, ensuring businesses meet deadlines with a sales u baffle machine.

Key Advantages of U-Shape Baffle Ceiling Machines

Streamlined Production Efficiency

A u baffle machine enhances efficiency by automating baffle production, reducing labor costs. The automatic baffle forming machine produces baffles faster than manual methods, saving time. Its accuracy minimizes material waste, making it a cost-effective choice. Businesses using a u shape baffle ceiling machine manufacturers benefit from faster project completion and increased profitability, ideal for high-demand markets.

Reliable Quality and Production Growth

A metal baffle ceiling machine delivers consistent baffle quality, meeting strict industry standards. This reliability fosters client confidence. Its scalability allows businesses to ramp up output for larger projects, supporting growth. Selecting trusted u shape baffle ceiling machine manufacturers china ensures equipment that maintains quality and expands production capacity effectively.

Where U-Shape Baffle Ceiling Machines Shine

Modern Commercial Interiors

U baffle ceiling machines are critical for crafting ceilings in commercial spaces like offices, retail centers, and airports. The baffles enhance acoustics and create a modern, open aesthetic. The supply baffle machine supports manufacturers by producing high volumes quickly, meeting tight construction timelines. This makes a buy baffle forming machine essential for delivering functional, stylish ceilings.

Specialized Acoustic Environments

U-shaped baffles excel in spaces requiring noise control, such as auditoriums, conference rooms, and restaurants. The buy baffle ceiling machine enables production of custom baffle sizes and finishes to suit specific acoustic and design needs. This versatility makes a ceiling u baffle machine invaluable for creating tailored ceiling solutions that enhance both function and appearance.

Customization with Xinbo

Xinbo automatic U-Shape Baffle Ceiling Machine offers bespoke solutions for businesses. Established in China in 2014, Xinbo provides ODM services, crafting machines to match unique baffle profiles. Their engineers deliver precise drawings, ensuring a u baffle machine customized to specifications. With in-house CNC machining, Xinbo ensures fast delivery and three quality inspections. Machines are designed for 20 or 40-foot containers, reducing shipping costs. Xinbo is a reliable source for high-quality, low cost u baffle machine production.

FAQs About U-Shape Baffle Ceiling Machines

What Is a U-Shape Baffle Ceiling Machine?

It’s a device that shapes metal into U-shaped baffles for modern ceiling systems.

How Fast Can a U-Baffle Machine Operate?

A u shape baffle ceiling machine produces baffles rapidly, ideal for large-scale projects.

Can a U-Baffle Machine Be Customized?

Yes, a u baffle machine customized supports various baffle sizes and designs.

What Materials Are Used in a U-Baffle Machine?

It processes aluminum, galvanized steel, or coated metals, typically 0.3-1.0 mm thick.

Why Invest in a U-Baffle Ceiling Machine?

It offers efficiency, consistent quality, and scalability for modern ceiling production.

Transform Your Ceiling Production with a U-Baffle Machine

A u shape baffle ceiling machine redefines ceiling manufacturing with its speed, precision, and versatility. From commercial spaces to acoustic havens, the baffle ceiling machine delivers stylish, noise-reducing solutions that meet modern demands. Opt for a machine with robust automation, durability, and custom options to lead the industry. Don’t let outdated tools dim your potential—ignite your production! Visit cnxinbo.net to explore Xinbo’s u baffle machines or contact their team for tailored advice to craft ceilings that captivate!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia