Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→Roller shutter doors play a key role in safety, warmth, and looks for business and factory spaces. From car sheds to storage buildings, their linked strips let doors open fast while giving strong guard. The best roll shutter door forming machine shines by handling the full making process—from opening metal rolls to exact cutting—cutting down scrap and pushing output speeds up to 30 meters per minute. As need rises for varied shapes, like ones with holes or PU-foamed slats, getting a machine with smart PLC controls turns into a must for keeping ahead.

What makes the top roller shutter door roll forming machine stand out is its skill to work with different metals like galvanized steel, aluminum, and color-coated sheets with errors as small as ±0.2mm. This care keeps panel forms steady, lowers fitting mistakes, and boosts door life.

At its center, a roller shutter door roll forming machine works by slow cold bending, where metal strips get shaped bit by bit without heat. This keeps the metal tough and smooth. The steps start with putting a coil into the machine. Then it ends with ready, cut-to-size slats for putting together. Unlike old pressing ways that make lots of waste, this steady flow cuts scrap to under 1%. So it becomes a green pick for big runs.

The wonder comes from step-by-step changes: each spot in the roll forming line adds small curves. This spreads force evenly on the metal. For example, a common setup may have 14-20 forming stations. The first ones smooth and line up the strip. Middle ones bend it into the slat shape. Last ones add strong edges like hems or locks.

Material Entry and Preparation: Coils up to 1.5 tons get unwound and flattened to fix flaws. This stops blocks later.

Forming Progression: Rollers, often built from tough 45# steel with chrome cover, lead the strip through exact spaces. They make shapes like C-profiles or foamed insides for warmth.

Length Control and Shearing: Sensors watch movement live. They start hydraulic cutters for neat, smooth edges at speeds that fit the line’s pace.

This bit-by-bit way not only boosts care but also lets changes happen, such as adding hole punches for air flow in one go.

No automatic shutter door roll forming machine is whole without its linked parts acting together. Here is a close view of the main pieces that bring trust:

The decoiler grips and sends the metal coil evenly. It uses hydraulic growth for firm hold. With leveling rollers, it makes sure entry is flat. This matters to stop waves in the end slat. Better models add servo motors for pull control. They keep steady feed even with thicknesses from 0.3mm to 1.2mm.

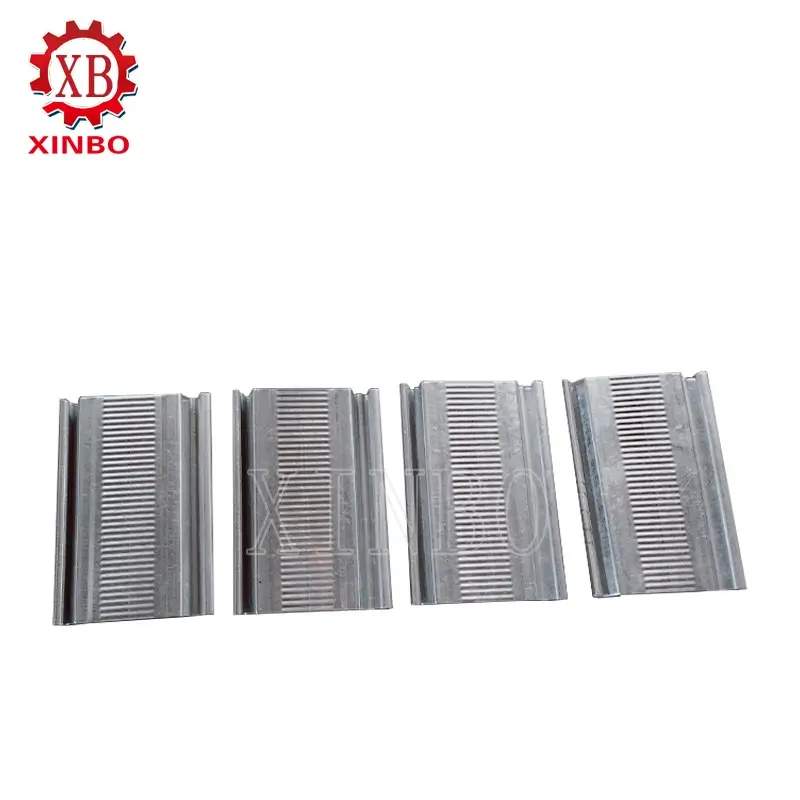

These act as the main workers: a set of paired top and bottom rollers fixed on a joined steel base. Ground shafts cut shakes. Changeable spaces fit various shapes. For instance, in making bent slats for pretty doors, stations can switch in under an hour.

After forming, a moving shear or straight cutter splits panels without stopping the line. This keeps speed high. Hydraulic setups give power—up to 10 tons—for clean splits. Cr12 blades last over 100,000 cycles.

A simple touch screen links with the PLC for setting changes, fault finds, and saved plans. The run-out table then piles or moves done pieces. It often has auto-piling to save work.

Together, these parts build a strong system. They turn basic inputs into top outputs with little worker help.

When checking the top features of a roller shutter door machine, look at ones that raise care and speed. New units show build-by-parts styles. This lets fast changes for making all from single-layer guard slats to double-wall warm panels. Power-saving motors and IoT links lift work more. They allow far checks to guess fix needs.

Care is not just talk—it’s built into every part. Rollers get CNC work and heat fix for hard surface over HRC 58. This holds shapes tight in fast runs.

Alignment and Tolerance Control: Laser-led setups keep evenness in 0.05mm. They stop shape shifts.

Material Versatility: Handles widths from 50mm to 200mm. Good for thin window shutters or wide factory doors.

Punching Integration: Extra servo-fed punches make holes for light pass. Hole spaces stay exact at ±0.3mm.

These points make sure the best roll shutter door forming machine gives slats that lock perfect. This raises door strength against wind up to 120 km/h.

Speed glows in auto work: lines hit 25-60 m/min paces. Non-stop cutting drops cycle times by 40% over hand ways.

PLC systems run steps on their own, from auto-flattening to safe restarts. Change-speed drives tweak paces on the fly. They fit material—slower for thick aluminum, quicker for thin steel.

Servo hydraulics lower power by 30%. Inline scrap takers grab edges. In big making, this saves thousands yearly.

Touch screens back many tongues. Alerts come for issues like low oil. Part frames let easy growth, like adding foam units for PU-filled slats. These raise warmth block by R-5.

With these features, a high-end shutter door roll forming machine speeds flow and grows with business.

The flex of a roller shutter door roll forming machine spreads its worth over fields, from shop fronts to big storage spots. Its output—tough, changeable slats—backs uses that need safety, warmth, and looks.

In business areas, hole-filled shapes from these machines let sight while stopping entry. They fit store fronts well. Factory spots like strong slats for fire-safe doors. Foam links meet UL rules.

Residential and Garage Doors: Small machines make quiet, hand-turn shutters for homes.

Logistics and Warehouses: Fast lines push wind-proof panels for load areas.

Retail and Hospitality: Bent or colored slats boost marks on shop fronts.

Past uses, the gains are clear: cut work by 50%, save material 5-10%, and get ROI in 18 months from more output.

Auto runs lower mistakes. They slash fix work by 70%. For OEM setups, quick shape switches let varied orders without stops.

Chrome-covered rollers stretch tool life to 5+ years. Low-waste steps fit green marks. End-users get doors that last 20,000 cycles with little care.

New firms can start with basic models. They upgrade to automatic shutter door roll forming machine types for round-clock work as need jumps.

These gains show why smart makers pick machines that mix care with real speed.

Keeping top work in your OEM door shutter roll forming machine needs active care. Daily looks stop 80% of breaks. They ensure long life and steady quality.

Stick to a step plan: daily oil on bearings, weekly roller checks, and monthly hydraulic fluid swaps. Clear junk from guides to skip marks on slats.

Lubrication Essentials: Pick food-safe oils on chains and gears for easy move.

Alignment Checks: Set stations every three months to hold ±0.1mm exact.

Software Updates: New firmware boosts PLC speed.

Problems like uneven bends often come from coil pull—tweak decoiler force. Blocks? Check leveling. Shakes point to shaft wear, fixed by smooth grind.

Cutting Errors: Sharp blades or reset sensors.

Profile Distortions: Line rollers again; try with scrap runs.

PLC Faults: Clear via checks; look manuals for codes.

Picking the best roll shutter door forming machine rests on wants: amount (pick 60m/min lines), metals (aluminum-fit rollers), and funds (count 2-year promises).

Assess Production Scale: Low amount? Hand decoiler works; high? Auto-piling.

Verify Certifications: CE and ISO promise safety and trust.

Test Customization: Ask shows for your shapes.

Focus on suppliers with training—many give on-spot setup for smooth fit.

Most models run at 15-30 meters per minute. High-end automatic versions hit 60 m/min for non-stop output.

Yes, part rollers and changeable stations allow special slat plans, from flat guard panels to bent pretty ones.

Small errors (±0.2mm) ensure smooth locks. They cut gaps that might hurt safety or warmth.

Common picks include galvanized steel (0.4-1.0mm thick), aluminum, and pre-painted coils. Some back PU foaming for better traits.

Daily oil and weekly looks are best. Full fixes every 6-12 months keep speed.

Find the top care and speed of XINBO‘s roll shutter door forming machines. They are made with over ten years of new ideas since 2014. As a trusted manufacturer and wholesale supplier, we give custom ODM answers that match your needs exact. They come with CE-certified quality and quick send.

Contact us now via email at serena@cnxinbo.net or chat for a free talk—change your making with XINBO care!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→