Roll Forming Machine, as the core equipment in the field of metal processing, its unique forming method and wide range of applications make it occupy a pivotal position in the modern manufacturing industry.

Working principle of roll forming machine

The working principle of the roll forming machine is based on the theory of plastic deformation, through the rollers on the metal material to apply high pressure and friction, so that its plastic flow and deformation under the constraint of the mold. Specifically, when the metal material is placed in the cavity of the mold, the rollers begin to rotate and apply pressure. As the rollers rotate and feed, the metal material gradually fills the mold cavity and achieves the desired shape and size. Roll forming process, the interaction between the roller and the mold is the key, they together determine the deformation of the metal material and the final shape.

Structure and composition of roll forming machine

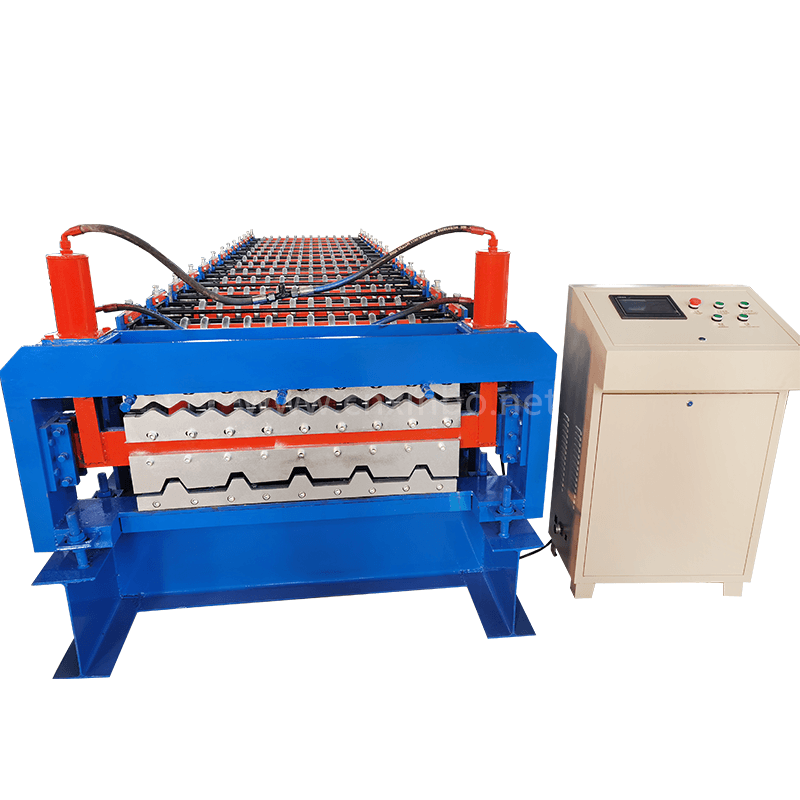

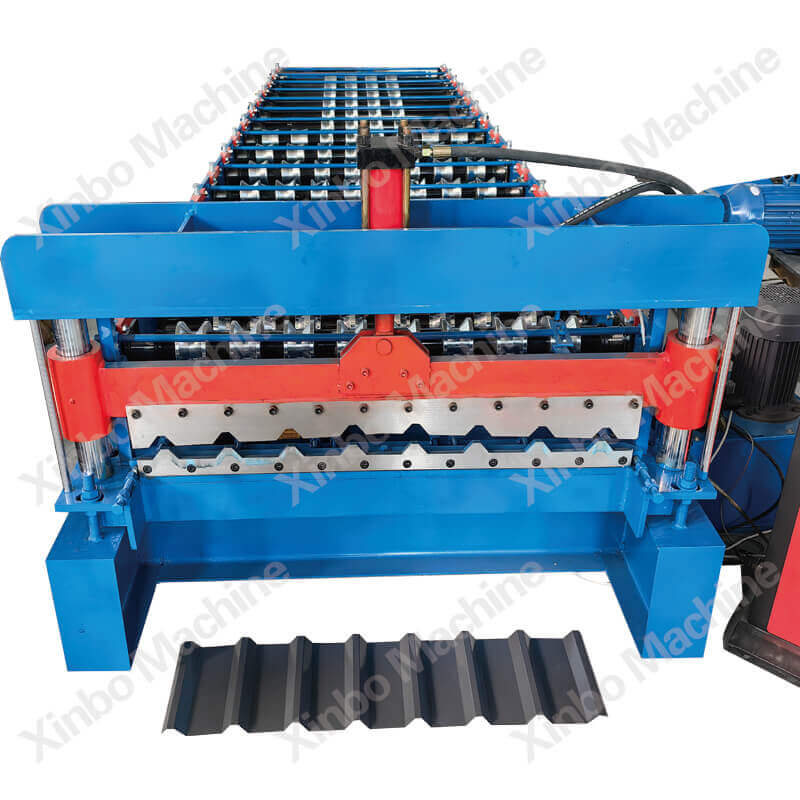

Roll forming machine is usually composed of host, transmission system, control system, lubrication system and auxiliary devices.

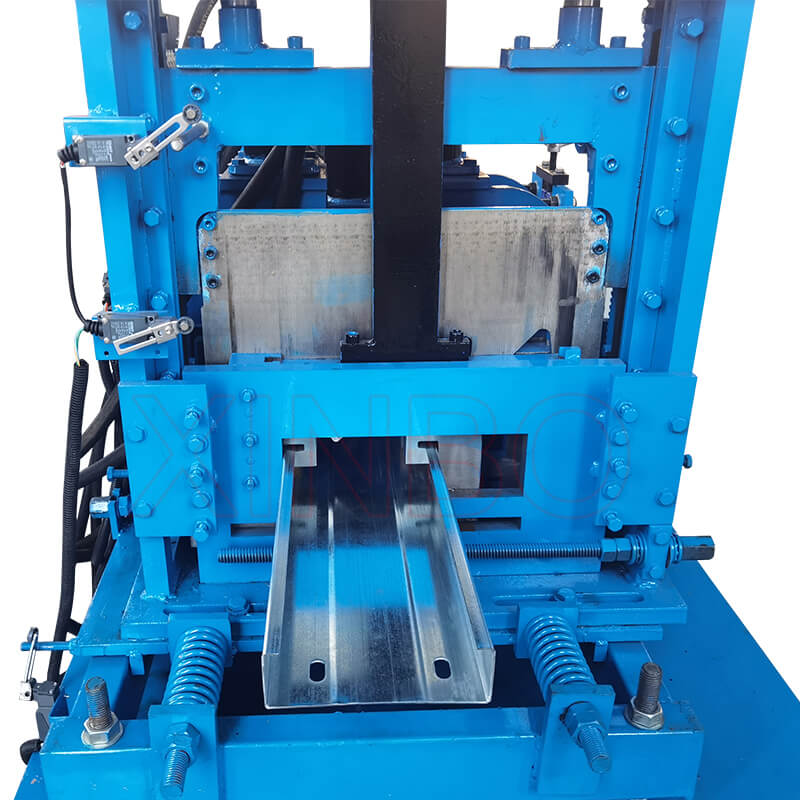

Host: including rollers, molds, tables and racks and other components. Roller is the executive part of the roll forming process, responsible for applying pressure and friction; mold is used to determine the final shape and size of the metal material; table is used to support and fix the mold to ensure the stability of the forming process.

Transmission system: It consists of a motor, reducer, drive shaft and coupling, etc., which is responsible for driving the rollers to rotate and feed. The transmission system needs to ensure that the rollers work at the appropriate speed and force to meet the molding requirements.

Control system: It includes electrical control cabinet, touch screen or PLC controller, etc., which is responsible for controlling the whole roll forming process. The control system can adjust the rotational speed, feed rate and pressure of the rollers according to the preset process parameters and actual requirements to ensure product quality and production efficiency.

Lubrication system: it consists of lubricant pump, oil tank, oil filter and nozzle, etc. It is responsible for providing the right amount of lubricant for the rollers and molds to reduce the friction and abrasion, and to ensure the long-term stable operation of the equipment.

Auxiliary devices: including feeding mechanism, fixtures, measuring devices and safety guards, etc., used to assist the smooth progress of the forming process, and ensure the safety of the operator.

Application field of roll forming machine

Roll forming machine has a wide range of applications in many industries, especially in the automotive, aviation, shipping, electric power and home appliances. In the automobile industry, key parts such as engine block, cylinder head, crankcase and so on can be produced by roll forming machine. In addition, roll forming machine can also be used to produce various shapes of tubes, bars and plates, etc., to provide high-quality metal products for various industries.

Advantages and Challenges of Roll Forming Machines

Roll forming machine has many advantages, such as high productivity, good product quality, high material utilization rate. Compared with the traditional cutting process, roll forming machine can reduce a large number of cutting waste, reduce the cost of raw materials. At the same time, the roll forming process produces less residual stress, which is conducive to improving the fatigue strength and service life of parts.

However, roll forming machines also face some challenges. First, the equipment investment is large, for small enterprises may constitute a large economic pressure. Second, the mold manufacturing cost is high, and for different materials and shapes need to customize different molds. In addition, roll forming requires high material properties, and some low-plasticity or high-strength materials may be difficult to roll form. Therefore, in the selection of roll forming machine, need to consider the material properties, product requirements and economic costs and other factors.

Roll forming machine operation and maintenance

Correct operation and maintenance is essential to ensure the normal operation and prolong the service life of the roll forming machine. Operators need to receive professional training, familiar with the structure and working principle of the equipment, and operate in strict accordance with the operating procedures. In the operation process, it is necessary to pay attention to the observation of the operating status of the equipment and product quality, timely adjustment of process parameters and check the wear and tear of equipment components.

Conclusion

As an important equipment in the field of metal processing, roll forming machine plays an important role in the manufacturing industry with its high efficiency, high precision and high quality. By gaining a deeper understanding of the working principle, structural composition, application areas, as well as advantages and challenges of roll forming machine, we can better utilize this advanced technology for industrial production. At the same time, with the continuous progress of science and technology and the ever-changing application requirements, the roll forming machine will continue to develop and innovate, injecting new vitality into the development of the manufacturing industry.

Spanish

Spanish