Buy Factory Direct Sales Ridge Cap Making Machine from China: What to Know

In the metal roofing business, a ridge cap roll forming machine plays a key role. It helps make important parts that seal and guard the top of sloped roofs. This tool quickly turns flat metal coils into well-shaped ridge caps. These caps provide good waterproofing, strong support, and nice looks for many building jobs.

As more people want strong metal roofing options, it helps to know the main features of a metal roof ridge cap roll forming machine. Buyers look for solid production ability. China has become a top place for making these machines. It offers modern tech along with lower costs that match world standards.

Understanding the Ridge Cap Roll Forming Machine

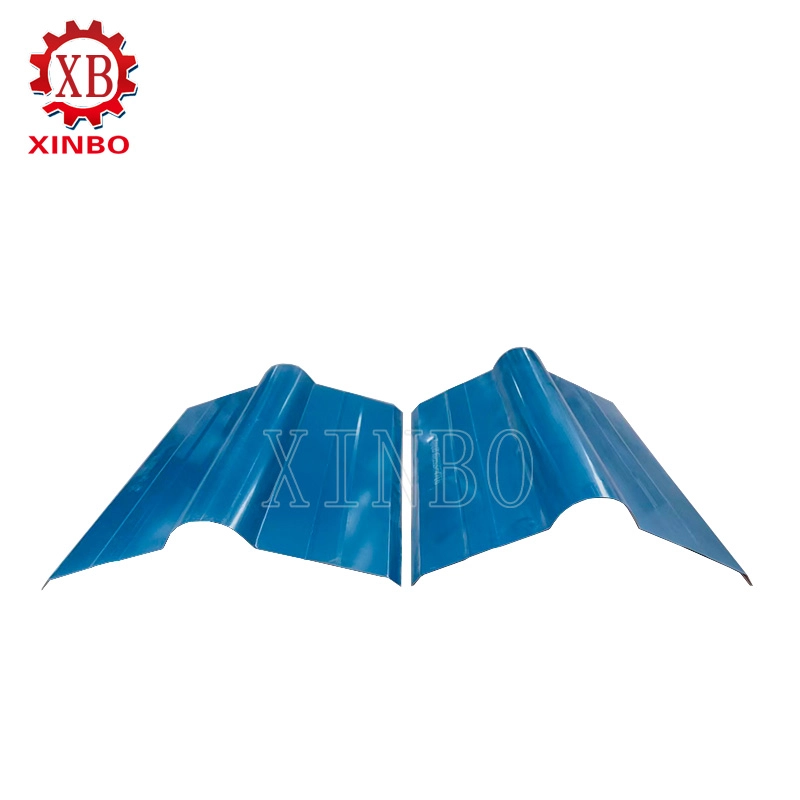

A ridge cap roll forming machine is special cold-forming gear. It bends and shapes metal sheets into ridge caps, sometimes called roof ridge closures. These parts cover the spot where two roof slopes come together. They stop water from leaking in, keep out wind-driven rain, and block debris buildup. They also improve how the roof looks.

The machine works in a steady way. A metal coil—often galvanized steel, PPGI, or aluminum—goes into the system. Rollers slowly shape the material into profiles like round, angular, half-round, or tile-effect styles. This process gives steady sizes, smooth finishes, and exact shapes. The final ridge caps fit well for homes, stores, and factories.

Usually, a roof ridge cap roll forming machine deals with material thicknesses from 0.3mm to 0.8mm. Coil widths range from 300mm to 800mm, based on the needed profile. Production speeds can hit 10-30 meters per minute. This allows fast work in busy places.

Key Components of a Ridge Cap Tile Roll Forming Machine

A typical ridge cap tile roll forming machine has several linked parts. They work together smoothly to give great results.

-

Decoiler — It uncoils the metal coil in a smooth manner (manual or automatic choices exist, often holding 3-5 ton loads).

-

Feeding and Guiding System — It lines up the sheet correctly to avoid mistakes. This often includes straightening rollers.

-

Roll Forming Station — This main area has 12-18 high-quality roller stations (made from Cr12 or 45# steel, hardened and chrome-plated for long life).

-

Step Pressing Unit (optional) — It creates tile-like patterns or steps right in the line for certain profiles.

-

Hydraulic Cutting System — It makes clean, exact cuts to set lengths through PLC control.

-

PLC Control Panel — A touch screen lets users set lengths, amounts, and other settings.

-

Hydraulic Station — It powers the cutter, press, and other hydraulic tasks.

-

Run-Out Table — It collects finished pieces for simple handling.

This setup offers steady work and cuts down on hand work.

How the China Ridge Cap Sheet Roll Forming Machine Works

The workflow of a china ridge cap sheet roll forming machine follows a clear order. It boosts efficiency and product quality. First, load the coil onto the decoiler. Then the material moves through straightening rollers to remove any bend or curve from the coil.

Next, it goes into the forming section. There, rollers shape it bit by bit—starting with basic bends, then sharpening angles, and adding things like ribs or vents if needed. For profiles that require steps or patterns, a pressing unit adds these features along the way.

After shaping, the hydraulic cutter cuts the profile to exact lengths. It uses encoder feedback for even results. The finished ridge caps come out onto a support table. They are ready for packing or use.

This automatic method lowers waste. It keeps tight measurements and allows changes for different roof types, such as corrugated, trapezoidal, or standing seam systems.

Advantages of Using a Factory Direct Sales Ridge Cap Making Machine

Choosing a factory direct sales ridge cap making machine brings several real benefits. Buying straight from the source skips middlemen. It gives access to good setups made just for your needs.

These machines produce steady results with little material damage. This comes from careful roller design and strong frames. High automation via PLC systems cuts down on mistakes from operators and lowers labor costs. It also allows fast changes for different profiles.

Durability stands out too. Parts are built to handle nonstop work in tough settings. The ridge caps that come out show strong weather resistance. This helps make roofs last longer.

Applications and Profiles in a Roof Ridge Cap Roll Forming Machine

A roof ridge cap roll forming machine makes many profiles to fit various roofing needs. Common ones include roll-top styles for basic curved closures, tile-effect versions that copy old glazed tiles, and flat or angled caps for modern looks.

These are used a lot in metal roofing for houses, warehouses, factories, and farm buildings. The ridge caps seal the roof peak well. They work with panels like corrugated sheets or trapezoidal profiles. Some vented types add airflow features for better attic air movement.

Customization makes it easy to match local building rules or building styles. This makes the machine useful for markets around the world.

Factors to Consider When Selecting a Ridge Cap Capping Roll Forming Machine

When looking at a ridge capping roll forming machine, pay attention to how well it handles needed material thicknesses and widths. Look at roller quality and the number of stations. These affect how accurate the profile is and how long it lasts.

Control systems need to be simple to use. They should have dependable PLC parts for steady work. Cutting accuracy and speed matter a lot for meeting production goals without losing quality.

Build strength is important. Seek heavy-duty frames and parts that keep things stable at high speeds. Ability to work with common materials like color-coated steel or aluminum adds more options.

Buy Factory Direct Sales Ridge Cap Making Machine Company Insights

Buying from a buy factory direct sales ridge cap making machine company makes the process easier. It offers direct talks for tech details and help. Many Chinese makers provide full solutions. These include setup guidance and after-sales support.

Direct contact allows custom changes. This ensures the machine fits your production aims exactly.

FAQ

What materials can a ridge cap roll forming machine process?

These machines typically handle galvanized steel, PPGI, color-coated steel, and aluminum coils with thicknesses of 0.3-0.8mm.

How precise is the cutting in a metal roof ridge cap roll forming machine?

Hydraulic cutting systems, combined with encoders and PLC control, achieve high accuracy, often within ±1-2mm for length consistency.

Can a ridge cap tile roll forming machine produce different profiles?

Yes, many are customizable for various shapes, such as round, half-round, stepped, or vented designs, by adjusting rollers and tooling.

What is the typical production speed?

Speeds range from 10-30 meters per minute, depending on the model and profile complexity.

Is the machine easy to operate?

Most feature intuitive PLC touch screens for setting parameters, making operation straightforward after initial training.

Contact XINBO for Your Ridge Cap Roll Forming Needs

If you’re ready to invest in a high-quality ridge cap roll forming machine, XINBO stands out as a trusted manufacturer specializing in reliable metal forming equipment. Since 2014, XINBO has focused on precision engineering and customer-oriented solutions, serving markets including Europe, the UK, and Canada with in-house design, advanced CNC machining, and strict three-step quality inspections to ensure dependable performance.

XINBO provides comprehensive support. They offer ODM customization tailored to specific production requirements, along with detailed technical support, clear cooperation processes covering demand communication, technical drawings, manufacturing, on-time shipping in standard 20ft or 40ft containers, and responsive after-sales service.

Their product range includes corrugated roof panel machines, roof wall panel roll forming machines, curving machines, metal IBR machines, decking floor machines, decorative panel machines, light keel machines, IBR iron sheet making machines, and other specialized cold-forming equipment optimized for international logistics and consistent quality.

Reach out to XINBO today. Discuss your needs and get expert tips on picking the best factory direct sales ridge cap making machine for your production line.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia