China Punching Hole Shutter Door Machine for Slats and Door Frame Profiles

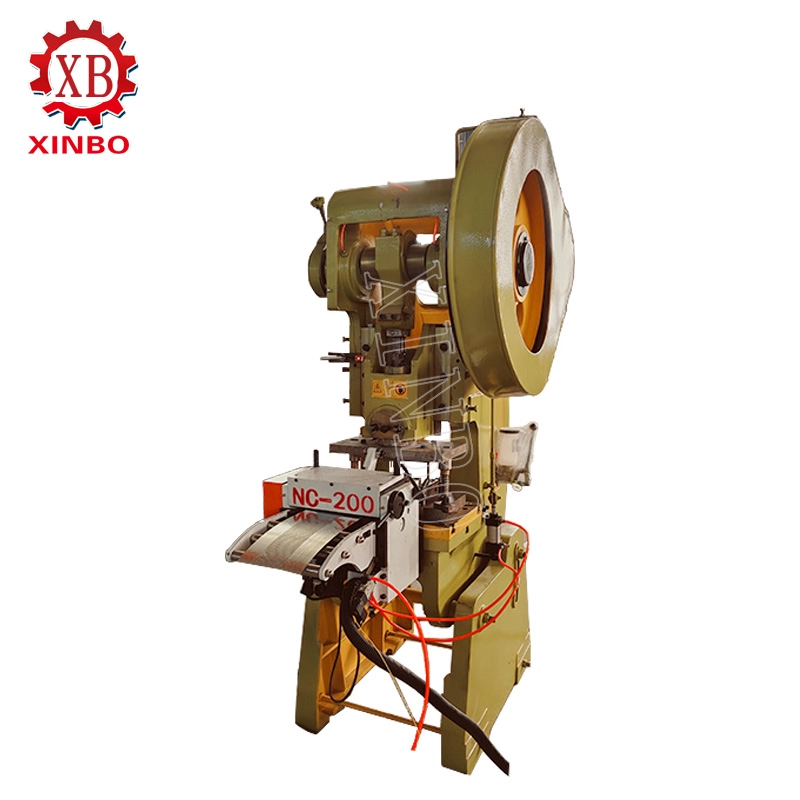

In the making of rolling shutter doors, exact punching stays a main need for proper function. This applies whether makers add air holes to slats or set fixing spots on door frames. A door punching machine like the NC-200 open back inclinable mechanical power press works as a special, steady choice for these jobs. It gives steady hole positions on metal strips used in shutter making.

Chinese manufacturers supply this kind of China punching hole shutter door machine. It combines mechanical power pressing with NC-controlled feeding. This setup fits medium-volume producers well. They get exact, repeatable outcomes without the full complexity of complete roll forming lines. In the same way, when used for structural parts, a door frame punching machine — usually built as an open back inclinable mechanical power press — uses the same ideas. It makes hinge cutouts, lock openings, or joining holes in frame profiles.

The NC-200 open back inclinable mechanical power press shows this type clearly. It is a strong C-frame mechanical press matched with a built-in NC servo feeder. Engineers design it specially for handling steel or aluminum coils in rolling shutter door work.

Visual Overview of the NC-200 Open Back Inclinable Mechanical Power Press

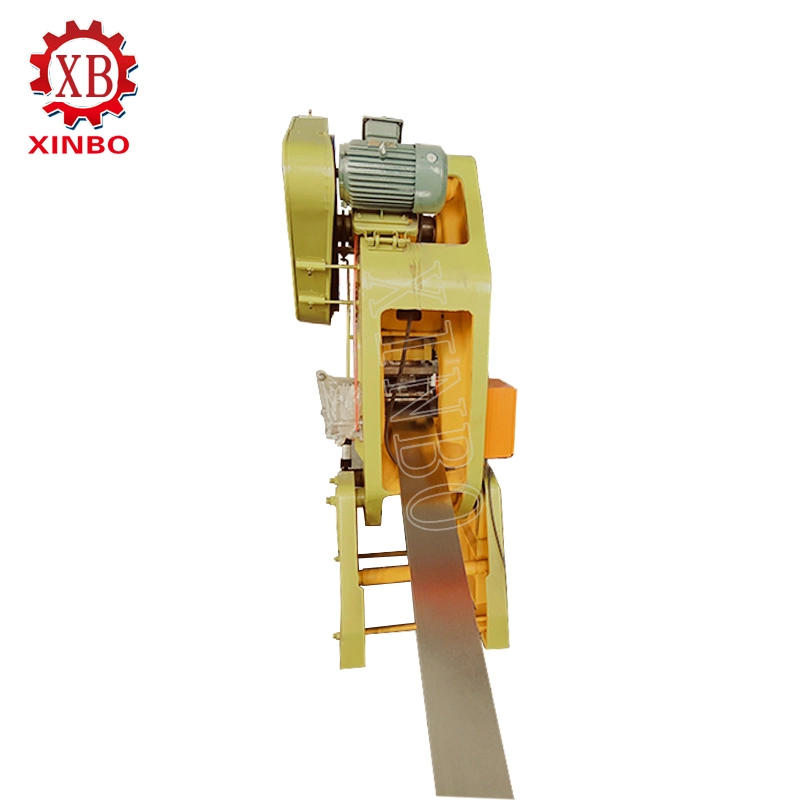

This door punching machine has a traditional C-frame build with a tiltable body. Operators can lean the press back easily. This helps with die access, scrap clearing, and watching during setup. A big flywheel sits on the top right side. It stores turning energy from the main motor. This keeps punching force steady even during long, fast runs.

The bright orange part at the lower right holds the NC servo feeder system. It includes upper and lower feed rolls. These rolls hold and move the metal strip forward very accurately. Material comes in from the right. It goes through built-in straightening rollers. Then it reaches the die zone for punching and leaves to the left. The control panel, often placed close by or built in, lets operators set feed lengths, punch timing, output numbers, and cycle settings.

This arrangement focuses on straight material movement. It reduces side bending and helps keep hole spacing exact. That spacing matters a lot for good slat alignment and frame joining.

Core Technical Features of the NC-200 Open Back Inclinable Mechanical Power Press

The NC-200 open back inclinable mechanical power press has about 200 kN (20 tons) of main force. It deals with usual shutter materials quite well:

-

Galvanized steel coils from 0.5 mm to 1.2 mm thick

-

Pre-painted steel strips

-

Aluminum alloys for lighter-duty rolling shutter applications

The tiltable open-back style offers plenty of throat depth. It takes wider strips (often up to 200–300 mm based on the die). At the same time, it keeps great access for operators and simple upkeep.

Important built-in parts include:

-

Mechanical Clutch and Brake System: It gives quick start and fast stop after each punch cycle. This boosts safety and allows exact stroke control.

-

Large Energy-Storing Flywheel: It supplies steady kinetic energy. This cuts speed changes during many fast strokes.

-

NC Servo Feeder Unit: Servo-driven feed rolls push the strip forward in set steps (usually 10–500 mm each). It reaches positioning repeat within ±0.2–0.3 mm. This works perfectly for even ventilation layouts or grouped hardware slots.

-

Die Mounting Area: Standard bolster and ram plate hold single-station, multi-station progressive, or compound dies. These support punching at the same time or one after another.

These points make the NC-200 open back inclinable mechanical power press very flexible. It works alone as a china punching hole shutter door machine or as a pre-punch spot before roll forming gear.

Typical Punching Applications in Shutter Door Production

The NC-200 open back inclinable mechanical power press does well at making key useful features on rolling shutter parts:

-

Ventilation and Visibility Perforations: Even round holes, slot openings, or staggered tiny perforations (e.g., 3–10 mm diameter). These allow air flow and some see-through ability in shops, stores, or factories.

-

Hardware Preparation Holes: Bigger cutouts for end locks, pull handles, rivet joins, guide blocks, or bottom bars.

-

Drainage and Condensation Slots: Long holes at the bottom edge to stop water buildup inside the rolled curtain.

-

Door Frame Profile Processing: With right wider or custom dies, this door frame punching machine setup punches hinge mortises, strike plate cutouts, bolt holes, or corner notches in U-shaped, L-shaped, or box-section frame profiles.

Die switches become simple because of the tiltable frame. It allows quick changes between slat patterns and frame tooling with very little stop time.

Operational Workflow Using the NC-200 Open Back Inclinable Mechanical Power Press

A normal production order for shutter slat material covers these steps:

-

Load the coil on a separate decoiler and guide the strip through entry guides and levelers.

-

Send the material through the built-in straightening rollers. This removes coil curve and gives flat entry to the feeder.

-

Set NC settings on the control screen: feed pitch (hole spacing), punch delay timing, strokes per piece, and batch amount.

-

Begin automatic cycles. The servo feeder moves the strip forward. The press makes the punch stroke. It repeats until the planned piece length finishes.

-

Cut finished slats or frame parts by hand or machine downstream.

For best results, many makers place the NC-200 open back inclinable mechanical power press before a roll forming line. It punches holes first. This keeps material straight and avoids shape issues after forming.

Benefits of This Punching Machine Design

-

Exceptional Repeatability: NC servo control removes hand placement mistakes. Every hole lines up perfectly over long runs.

-

Energy-Efficient Operation: The flywheel-driven mechanical setup uses power mostly during the real punch stroke. It needs less steady energy than many hydraulic options.

-

Compact and Accessible Footprint: The C-frame tiltable build fits nicely in small workshops. It still gives better die access and clear view.

-

Proven Durability: Heavy-duty cast iron or built steel frame stands millions of cycles with normal care.

-

Flexible Customization: Dies can get made or changed fast for different market wants — from strong solid shutters to ones with ventilation holes or tiny perforations for looks.

Maintenance Guidelines for Long-Term Performance

To keep accuracy and trust over many years:

-

Lubricate flywheel bearings, slide gibs, and feeder rolls as scheduled.

-

Check clutch and brake linings for wear now and then. Adjust clearances when needed.

-

Clean the die and bolster area after every shift. This stops metal bits from building up.

-

Look at servo feeder roll pressure, alignment, and belt tension each month.

-

Test NC positioning accuracy on a sample strip at set times (e.g., every three months).

Following these steps keeps the NC-200 open back inclinable mechanical power press running within close limits all the time.

FAQ

What thickness range does the NC-200 open back inclinable mechanical power press handle for shutter slats?

It reliably processes galvanized steel and aluminum from 0.5 mm to 1.2 mm, with minor adjustments for material hardness and tensile strength.

How precise is hole positioning with the integrated NC servo feeder?

Repeat accuracy typically reaches ±0.2–0.3 mm, more than sufficient for consistent ventilation patterns, hardware alignment, and frame assembly.

Can this door punching machine process door frame profiles?

Yes — with suitable wider or custom dies, it effectively punches hinge slots, lock recesses, or assembly notches in frame sections within the machine’s throat capacity.

What hole patterns are common in china punching hole shutter door machine applications?

Round ventilation holes, micro-perforations for visibility, elongated drainage slots, grouped hardware openings, and custom security patterns.

Is the inclinable feature useful in daily operation?

Yes — it greatly simplifies die installation, removal, scrap clearance, and visual inspection during setup, adjustment, and troubleshooting.

How does it integrate with roll forming lines?

It commonly functions as a standalone pre-punch unit or inline station before the forming rollers, often with a loop accumulator to buffer material tension and flow.

Ready to Upgrade Your Shutter Door Production? Contact XINBO Today

If you’re seeking a proven, precision-focused solution for perforating rolling shutter slats and door frame profiles, XINBO specializes in machines like the NC-200 open back inclinable mechanical power press and related equipment. With deep expertise in customizing punching and feeding systems for the shutter door industry, XINBO delivers reliable, high-performance technology tailored to your exact production requirements. Reach out to XINBO today to discuss how this equipment can optimize your workflow, improve output quality, and support your business growth. Contact via their official channels for detailed consultations, technical specifications, and personalized support.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia