Good quality

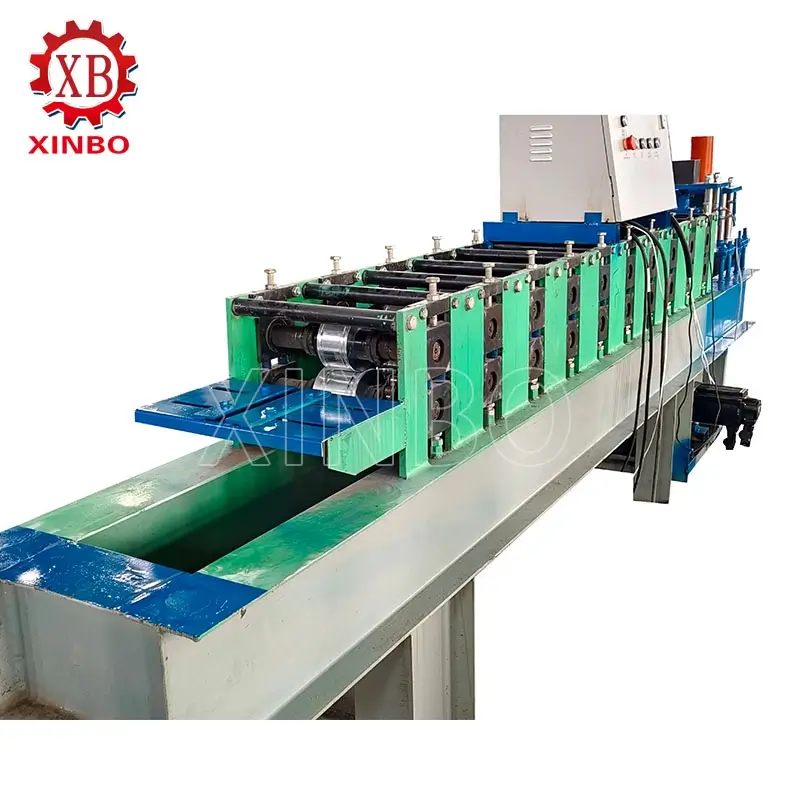

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→A U channel roll forming machine with hole punch is a type of industrial equipment that shapes flat metal into U-shaped channels and punches holes into the material at the same time. This dual-function capability makes it an efficient choice for businesses that need U-shaped profiles with specific hole patterns.

The machine is commonly used in fields such as construction, automotive, solar energy, and industrial storage. It helps manufacturers produce high-quality components in large volumes with great accuracy. This makes the u channel forming machine an essential tool in modern fabrication processes.

Modern U channel roll forming machines include several advanced features. One important feature is the automated hole-punching module. This allows for quick and accurate hole placement, which is important for assembly and installation. The punching system can be adjusted to create different shapes of holes such as round, square, or long slots.

Another key feature is adjustable rollers. These rollers help create U channels in various sizes, allowing users to change the depth and width of the profiles. The machines are also compatible with many types of metal materials, including galvanized steel, stainless steel, and aluminum. This level of flexibility is what makes the custom u channel roll forming machine a valuable asset in multiple industries.

The roll forming system is the heart of any u channel roll forming machine. It uses multiple sets of rollers to gradually bend the flat metal sheet into the U shape. This step-by-step forming ensures the metal does not crack or lose its strength during the process.

The forming section is usually controlled by a CNC system, which keeps every roller in the correct position. This technology allows for consistent output even when producing thousands of pieces. It also allows for minor adjustments without having to stop the machine completely, helping maintain production speed and quality.

The punching unit is designed to work at high speed while keeping the hole placement accurate. It is often powered by hydraulic or servo-driven systems. These systems provide strong and fast punching power, making it easy to punch through thick metal sheets.

The hole pattern can be changed depending on the needs of the project. Some projects need simple round holes, while others require square or slotted holes. A machine to create u channel with customizable punching options is a smart choice for those who need special profiles.

Most machines come with a modern control system that is easy to operate. The PLC panel lets workers set hole positions, adjust speed, and monitor the machine’s performance. Built-in sensors track things like alignment and forming pressure to avoid errors.

This automation reduces the need for manual labor and improves product quality. By combining forming and punching in a single line, the OEM u channel roll forming machine provides both speed and efficiency.

The construction industry is one of the main users of U channel forming machines. These machines help produce parts like structural frames, roof gutters, and wall supports. Many of these components need holes for screws, bolts, or wiring, so a roll forming machine with a punching system is very useful.

For example, in modular construction, pre-punched U channels are used to make the assembly process faster and easier. Builders can connect parts without needing to drill holes manually. The china u channel forming machine supports this demand by delivering high-speed and high-precision forming.

In the solar energy sector, U channels are often used as mounting rails for solar panels. These rails must be strong, lightweight, and pre-drilled for fast installation. A china u channel roll forming machine helps produce these profiles in bulk, supporting the growth of renewable energy projects.

In factories and warehouses, adjustable shelving systems are common. These systems rely on U channels with pre-punched holes, allowing shelves to be moved as needed. The u channel forming machine factory can design machines that create custom patterns and sizes, matching the specific needs of different storage setups.

One major benefit of using a U channel roll forming machine is its ability to produce accurate results. Manual punching and cutting often lead to mistakes, wasted material, and slow production. Roll forming machines solve this problem by combining forming and punching in one process. This can improve speed by 30 to 50 percent.

Precision is also improved because the machine follows exact patterns. Every U channel produced is the same as the last, which is very important in large-scale projects.

Manufacturers often need special designs that cannot be found in standard machines. That is where custom u channel roll forming machines come in. These machines can be built with unique rollers, hole patterns, and control systems.

For businesses that need something very specific, OEM u channel roll forming machines offer a solution. They are designed from the start to match the customer’s technical and size requirements.

Machines made in China often come with factory-direct prices, making them more affordable. Companies like Xinbo provide high-quality machines at lower prices because they handle both design and manufacturing in-house.

This cost advantage, along with lower labor needs and reduced waste, means that a china u channel roll forming machine can offer long-term savings for many businesses.

Before buying a roll forming machine, it is important to make sure it can handle the types of metal being used. Different projects require different materials and thickness levels. The machine should support a range of thicknesses without needing major changes.

The production speed and level of automation are key factors. For large projects, machines with higher speeds and full automation are more efficient. Evaluating how many meters the machine can produce per minute helps match it to the project’s demands.

A good machine also needs good support. Suppliers that offer spare parts, training, and help with setup are a better choice. A u channel forming machine factory that provides strong after-sales service can prevent long delays if something goes wrong.

Daily maintenance helps keep the machine in good condition. The rollers should be cleaned and oiled regularly. The punching blades should be checked for wear and replaced if needed.

Each month, the machine’s sensors and alignment should be tested. Emergency stop features must work correctly to avoid accidents.

Once a year, a full check should be done. This includes replacing old parts and updating the software if needed. With proper care, a U channel roll forming machine can last for many years.

Xinbo has experience in building machines that meet specific needs. The company uses CAD tools to create custom designs and can deliver the blueprints quickly. This helps shorten the time between the idea and the final product.

All machines go through three rounds of quality checks. This ensures that every u channel roll forming machine is built to meet safety and performance standards. From raw materials to final assembly, each step is carefully controlled.

Xinbo also focuses on efficient shipping. Machines are designed to fit in standard shipping containers, which lowers transportation costs. With experience in global logistics, orders can be delivered on time to many countries.

Struggles with slow or inaccurate metal forming can be solved with the right equipment. Xinbo offers free consultations to help businesses choose the best machine to create U channel.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→