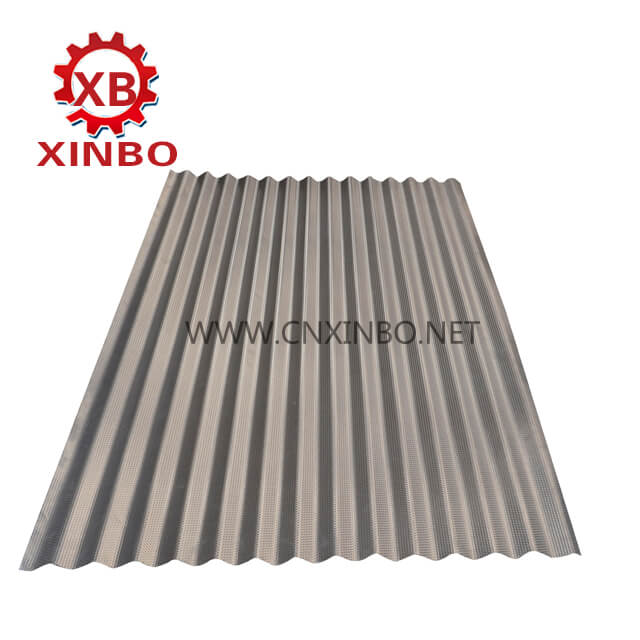

corrugation roof panel machine

A corrugation roof panel machine is a specialized piece of equipment used in the construction industry to manufacture corrugated roof panels. These panels are widely used in residential, commercial, and industrial buildings due to their durability, strength, and aesthetic appeal.

The machine is designed to automate the process of creating corrugated roof panels, which traditionally required manual labor and time-consuming techniques. With the help of this machine, manufacturers can produce high-quality panels quickly and efficiently, meeting the demands of the construction industry.

The corrugation roof panel machine consists of several essential components. The first component is the decoiler, which is responsible for holding and unwinding the metal coil that will be used to create the panels. The coil is fed into the machine, passing through various rollers and forming stations.

The next component is the roll forming system, which shapes the metal coil into the desired corrugated profile. This system consists of a series of rollers that gradually bend and shape the metal, creating the distinctive corrugated pattern. The roll forming system is adjustable, allowing manufacturers to produce panels of different sizes and profiles.

After the metal has been formed into the corrugated shape, it goes through a cutting system. This system is equipped with a flying shear, which cuts the panels to the required length. The cutting process is precise and efficient, ensuring that each panel is cut accurately.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia