Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

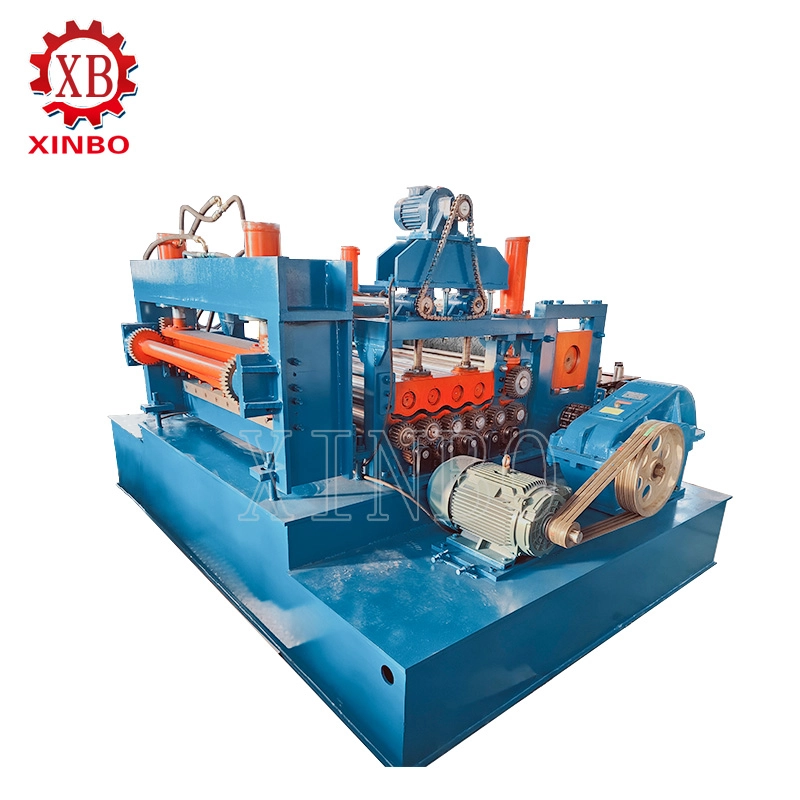

VIEW MORE→Custom Embossing Roll Forming Machines for Metal Sheet Production form a special group of equipment. They blend exact embossing features right into the roll forming process. These machines let manufacturers make textured, patterned metal sheets. The sheets gain better looks, added function, and strength perks. By mixing steady roll forming with embossing, Custom Embossing Roll Forming Machines make solid metal parts fast. They serve many uses in worldwide sectors.

Embossing Roll Forming Machines work on cold forming ideas. Metal coils or sheets get shaped and textured slowly. Little heat gets used. The main setup feeds a flat metal strip, often from a coil, through matched rollers. Early stations even out and direct the material. Special embossing stations use strong pressure. They employ paired male and female patterned rollers. This deforms the surface in a lasting way. It makes raised or sunk designs, like diamond patterns, checkered textures, or custom shapes. Thickness stays even all through.

The steps start with uncoiling the metal sheet. Next comes leveling to fix coil bend. Then the material goes into the embossing part. There, matched upper and lower rollers work together. They often use tough alloys like 9Cr2Mo with hard chrome plating. These apply steady pressure. Tools like screw or hydraulic systems adjust force. This keeps depth and sharpness the same. After embossing, more roll forming stations can shape profiles if required. Inline cutting gives exact lengths.

This mix sets Custom Embossing Roll Forming Machines from China apart from basic embossers. It allows smooth making of textured profiles in one go. Machines deal with different thicknesses. They manage aluminum up to 1.0mm, color steel up to 0.7mm, and steel up to 2.5mm or more. This depends on the build.

The flow of Embossing Roll Forming Machines stresses speed and accuracy. A usual line has:

Decoiler/Uncoiler: Holds and unwinds the metal coil evenly.

Leveler/Straightener: Removes curve for flat start.

Feeder: Servo-driven for right steps.

Embossing Station: Paired carved rollers press down. This causes lasting change to copy patterns. Upper rollers stay set. Lower ones shift for force.

Forming Stations (if profiled): Slow bending for extra forms.

Cutoff/Shear: Hydraulic or flying shear for length match.

Runout Table/Stacker: Gathers done sheets.

Speed goes from 0-30 m/min with frequency change control. This makes it flexible. Patterns come from squeeze force between raised-sunk dies. They make three-D effects without cutting material. This cold method hardens the metal a bit. It raises strength.

Custom Embossing Roll Forming Machines from China shine in range. They fit extra steps like punching or notching with embossing. This makes full parts in fast lines.

Custom Embossing Roll Forming Machines give clear gains over old ways:

Enhanced Strength-to-Weight Ratio: Embossing adds stiffness. It lets thinner sheets work the same. This cuts material costs.

Superior Aesthetics and Functionality: Patterns give non-slip faces, nice looks, or marks. They also boost lasting power.

High Production Efficiency: Steady work handles big batches with little stop time. It beats stamping or press ways.

Customization Flexibility: Rollers carved to set details allow special patterns. These run from diamond checker plates to set textures in OEM Custom Embossing Roll Forming Machines.

Cost-Effectiveness: Inline steps skip extra work. This lowers work and move costs.

Consistency and Precision: Auto controls keep even depth, match, and quality in long runs for factory-produced Embossing Roll Forming Machines.

These perks make Custom Embossing Roll Forming Machines for Metal Sheet Production perfect for tough making spots around the world.

Embossing Roll Forming Machines aid sectors that need textured metal sheets:

Construction and Architecture: Diamond or checkered patterns for non-slip floors, wall panels, side covers, and roof parts.

Transportation and Automotive: Textured faces for car insides, truck beds, or trim pieces.

Industrial and Manufacturing: Non-slip stands, machine covers, air ducts, and tool panels.

Decorative and Furniture: Raised shapes for nice metal chairs, signs, or room highlights.

Specialized Uses: Heat covers, sandwich panel parts, or strength adds.

Patterns like diamond tread improve safety and hold. Custom shapes aid marks in uses from ODM Custom Embossing Roll Forming Machines.

Embossing Roll Forming Machines can make many pattern types. They use custom-carved roller pairs. These meet function and look needs. Usual patterns include:

Diamond Pattern (also known as diamond tread or checker): Raised diamond shapes for strong non-slip traits. They fit floors, steps, and car stands.

Checkered Pattern: Basic back-and-forth raised squares or diamonds. They give good hold and lasting in work and move uses.

Stucco Pattern (orange peel or pebble texture): A bumpy, dented face like orange skin or stucco. It suits nice panels, fridge gear, and build parts where light spread and soft looks matter.

Five Bar (or Multi-Bar) Pattern: Side-by-side raised bars in five groups. They offer firm pull for heavy floors and ramps.

Three Bar or Compass Pattern: Easier line or spoke bar shapes for fair hold needs.

Other Specialized Textures: Including water ripple, small bead, linen, leather grain, honeycomb, pyramid, or full custom shapes based on client details.

These patterns come from exact carving on rollers. This lets Custom Embossing Roll Forming Machines manufacturer fixes match set job needs. They cover high-pull function faces to detailed nice ends.

Current Custom Embossing Roll Forming Machines add forward features:

Strong frames from welded steel plates for steady under strong press.

Tough, exact-carved rollers for long life and pattern truth.

Variable frequency drives for speed rule.

Modular builds for simple care and pattern swaps.

PLC controls for auto, watch, and tweaks.

Material fit covers galvanized steel, stainless steel, aluminum, and pre-coated sheets. Force rule keeps best change without breaks in China-based Custom Embossing Roll Forming Machines.

These machines deal with bendable metals like aluminum, galvanized steel, color steel, stainless steel, and copper. Thicknesses run from 0.2mm to 5.0mm based on the model.

Embossing causes lasting change. It raises stiffness and strength-to-weight ratio. It adds textures for non-slip or nice aims.

Yes, rollers get carved to customer details. This allows special designs like diamond, rice-grain, checkered, stucco/orange peel, or own patterns.

Speeds go from 1-30 m/min. They adjust through frequency changers for best quality and output.

Yes. Steady work and auto make Embossing Roll Forming Machines great for big metal sheet making. Results stay the same.

For exact-built Custom Embossing Roll Forming Machines fit to set metal sheet making needs, XINBO offers pro fixes. As a focused manufacturer begun in 2014 with wide skill in metal shaping and roll forming tech, XINBO gives custom-built gear to world standards. This includes strong build, in-house CNC work, and ODM/OEM skills. Their embossing machines blend well for solid textured results. They back uses from build to work fields. Reach XINBO now via official ways to talk project needs. See how their custom fixes can boost making speed and part quality.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→