Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

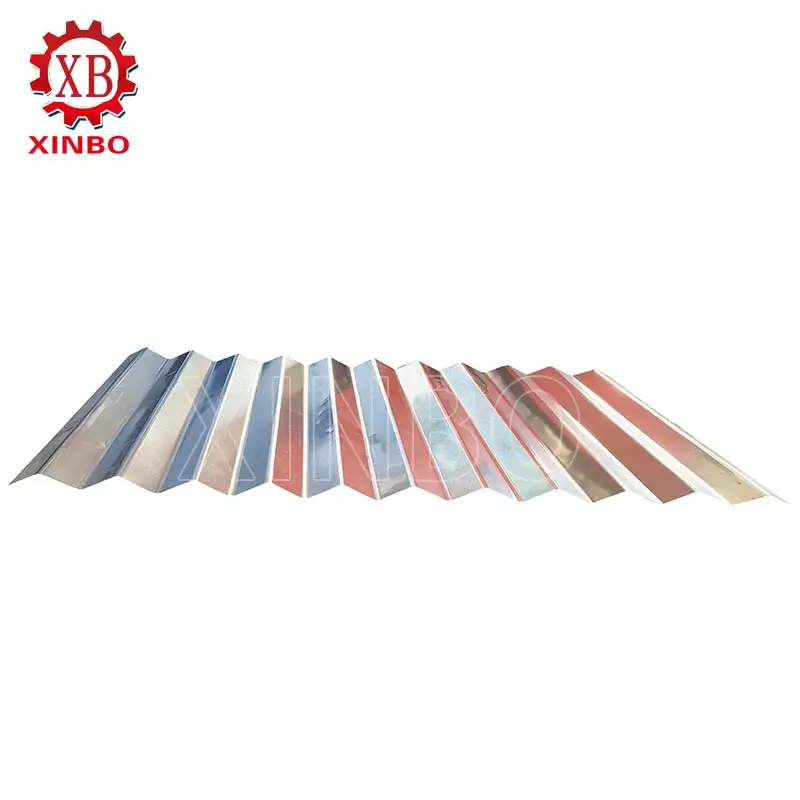

VIEW MORE→In today’s building world, speed and accuracy matter. Double layer roof panel roll forming machines have changed how roofing panels are made. They offer a quick, neat solution for different building needs. This advanced tool makes metal roofing panels with two-layer designs. It can create two shapes, like trapezoidal and corrugated sheets, without changing machines or long setups.

The dual-layer design meets the need for flexible production lines. These handle various panel types, such as wall cladding or roofing sheets, for factories, warehouses, garages, and exhibition centers. With automated features like PLC control systems and hydraulic cutting, these machines keep quality steady. They cut manual work, boost safety, and reduce mistakes.

These machines save money. They combine two forming lines into one unit. This cuts the need for extra machines. It saves up to 50% of factory floor space compared to two single-layer systems. This lowers equipment costs a lot.

Shared parts, like motors and hydraulic systems, reduce running costs. One machine replaces two, saving 30-40% on buying costs. Energy use drops by 20-30% due to smart power use across both layers.

Material waste is low. Precise cuts and efficient feeding save 10-15% on raw materials like steel coils. These savings boost profits and speed up investment returns.

Modern building projects need flexibility and speed without losing quality. Double layer roof panel roll forming machines deliver with their sturdy design and smart automation. They turn metal coils into finished roofing panels in a step-by-step process.

The machines work with materials like galvanized steel, galvalume, and color-coated steel. Thicknesses range from 0.3mm to 1.5mm. The sheet moves through stands, bending slowly into shapes like trapezoidal ribs or corrugations. Automated controls ensure precision at every step, from feeding to cutting and stacking.

Their flexibility suits homes to large industrial buildings.

Efficient production saves time and boosts profits. Unlike single-layer machines that need setup changes for different shapes, this system uses upper and lower stations. It makes varied shapes quickly.

A clutch switches between profiles easily. This cuts setup time from hours to minutes. It increases output. Automation reduces labor needs by up to 70%. This lets manufacturers use resources better while keeping steady quality across panel types.

img.trapezoidal roof sheet produced by Double Layer Roof Panel Roll Forming Machine.webp

Precise engineering ensures panels meet exact specs. This is key for strength and looks. Rollers use high-grade No.45 steel, chrome-plated for durability. They reach HRC55-60 hardness.

Hydraulic cutting systems with Cr12 steel blades make clean cuts. They stay within ±2mm accuracy using PLC input. This cuts waste. The cuts are precise and automated.

Sturdy frames from heavy-duty H-section steel support long-term use. They need little maintenance.

Speed is vital for tight project deadlines. This automatic double layer roof panel roll forming machine shines. It produces up to 60m/min in top setups.

High-speed motors (up to 15kW) drive chain systems. These keep operations smooth under heavy loads. With thousands of meters output daily, these machines scale production without extra labor or space.

This makes them great for big infrastructure projects with strict timelines.

As building tech grows greener and smarter, roll forming machines evolve too. Modern units use advanced PLC systems. These give real-time feedback via encoders for better accuracy.

Some models have automatic stackers up to 9 meters long. These cut manual handling after cutting. Chrome-treated shafts boost longevity. Safety guards protect workers.

These updates improve safety and meet green building standards by cutting waste and energy use.

When picking a double layer roof panel roll forming machine, consider these:

Material Compatibility: Ensure it handles coil widths up to 1250mm and thicknesses of 0.3–1.5mm.

Profile Flexibility: Choose models that switch easily between trapezoidal and corrugated shapes.

Automation Level: Pick PLC-controlled systems with hydraulic decoilers and stackers.

Speed & Power: Select based on needed speed (15–25m/min standard; up to 60m/min available).

Durability: Check roller material (e.g., No.45 steel) and shaft diameter (70–75mm) for reliability.

Trusted suppliers like XinBo offer custom solutions for global markets, including Europe, Middle East, Africa, America, and South America.

Using materials well keeps costs low. Double layer systems excel here with precise engineering. PLC-controlled cutting keeps waste below 2%. It protects coil strength during cold-forming. This saves raw materials and lowers environmental impact.

The cold-forming process keeps metal strong. It avoids the need for thicker, pricier materials. This cuts costs without hurting performance.

They work with galvanized steel, galvalume sheets, or color-coated coils, 0.3mm–1.5mm thick.

Yes. The dual-layer system switches between profiles using clutch mechanisms.

Standard speeds are 15–25m/min. Advanced models hit up to 60m/min based on setup.

Yes. Combining two functions in one footprint makes it great for limited spaces.

For reliable performance, Xinbo machine making company is a top choice. Started in 2014, it’s a 100% manufacturer. Its roll forming machines are designed and built to customer requests. They meet Euro standards like CE certification. Exports reach Europe, USA, Nigeria, and Brazil.

With OEM/ODM customization, XinBo delivers quality products and one-stop service. This covers design, assembly, installation, and after-sales support. Contact XinBo today for your machines.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→