Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→A floor deck machine plays a key role in making metal floor decks. These decks are vital for strong and dependable building structures. The machines form metal into exact shapes, ensuring toughness and speed in construction projects.

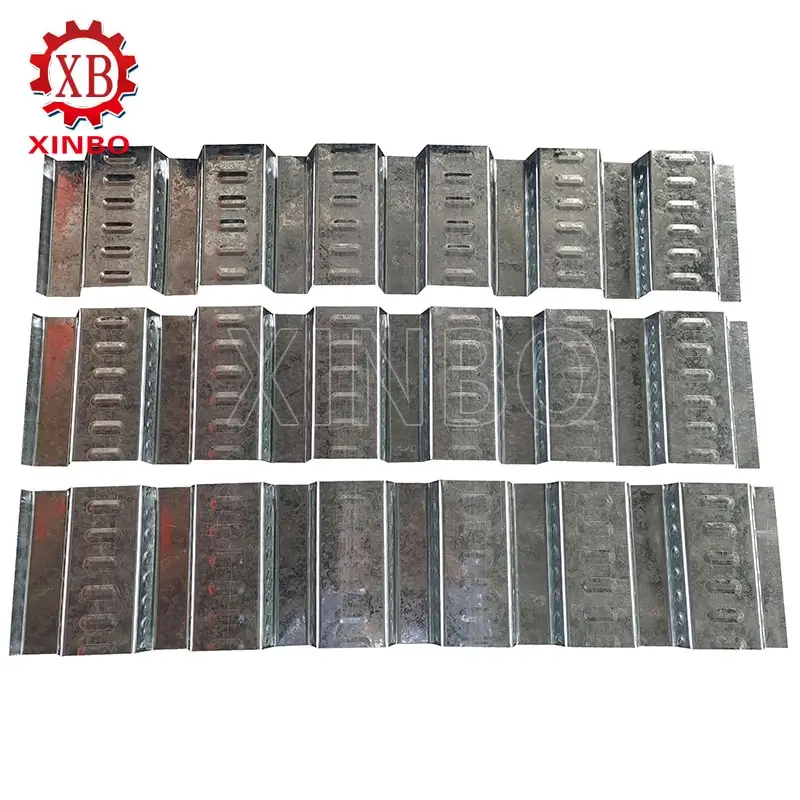

A floor deck roll forming machine, also called a floor decking machine, turns flat metal coils into structured floor deck shapes for construction. These decks create a solid base for floors in buildings. They support concrete and other materials. The roll forming process starts by feeding metal coils through rollers. These rollers slowly shape the metal into specific designs, like trapezoidal or re-entrant shapes. Key parts of a floor deck making machine include an uncoiler to hold the metal coil, roll forming stations to shape it, a hydraulic cutting system for accurate cuts, and a PLC control panel for automatic operation.

Modern floor deck roll forming machines achieve great accuracy, often within ±0.1mm. This happens because of advanced servo motors and PLC systems. This precision is important for ensuring floor decks are strong in buildings. Laser sensors and automatic feedback loops watch the production process. They spot any errors and adjust settings to reduce material waste. For example, a high quality floor deck roll forming machine ensures every deck meets exact standards. This cuts mistakes and improves project reliability.

Compared to old manufacturing ways, an efficient floor deck roll forming machine has big benefits. These machines can make decks up to 50% faster than older methods. They also use 30% less energy. A study from Xinbo, a trusted deck floor roll forming machine manufacturer, shows their fast machines helped a factory shorten project timelines by 40%. By making production smoother and lowering energy costs, a china floor deck forming machine offers a budget-friendly solution. It helps businesses boost efficiency without losing quality.

Construction projects often need unique deck shapes or specific material thicknesses, usually from 0.8mm to 1.5mm for steel. An odm floor deck roll forming machine can be adjusted to meet these needs. It produces varied shapes like trapezoidal or re-entrant designs. Xinbo’s customization services let clients set exact requirements. This ensures the machine fits project goals. Their container-friendly designs also make shipping simpler. This helps deliver a steel floor decking roll forming machine to global clients quickly.

A floor decking roll forming machine is widely used in commercial and residential building projects. It creates lightweight, fire-resistant floor decks. These decks are perfect for tall buildings and prefabricated homes, where speed and safety matter. The accuracy of an advanced floor decking machine ensures decks fit perfectly into building frameworks. They support concrete slabs and improve structural strength.

In industrial places, like factories and warehouses, floor decks must handle heavy loads from machines or storage systems. A floor deck forming machine factory makes decks with high load-bearing ability. These are ideal for mezzanines or equipment platforms.

The growth of renewable energy has raised demand for special floor decks. A precision metal floor deck manufacturing machine can make galvanized steel decks for solar farm walkways or structural supports. These decks resist rust, ensuring they last in outdoor settings. The ability of a floor deck roll forming machine to handle tough materials makes it vital for sustainable infrastructure projects.

Running an efficient floor deck roll forming machine follows a clear process. First, metal coils are loaded and aligned in the uncoiler. Next, the PLC interface sets the desired deck shape. During production, ongoing quality checks ensure each deck meets standards. Finally, automatic stacking and packaging systems prepare decks for transport. This smooth process boosts efficiency and reduces mistakes in production.

Regular care is key to keeping a steel floor decking roll forming machine in great shape. Daily lubrication of rollers prevents wear and keeps operation smooth. Monthly calibration of the hydraulic system maintains cutting accuracy.

Choosing a dependable floor deck roll forming machine manufacturer needs careful thought. Manufacturers with in-house CNC machining skills, like Xinbo, ensure quality control and faster production. Certifications like CE, ISO, and OSHA compliance show a focus on safety and global standards. Also, strong after-sales support, like on-site training and spare parts availability, is important for long-term success. Xinbo’s three-step inspection process guarantees every floor deck making machine meets strict quality rules. This gives clients trust in their investment.

When picking a supplier, avoid certain warning signs. Manufacturers with limited customization options or unclear delivery timelines may cause delays or poor results. A lack of third-party certifications can also mean unreliable quality. Partnering with an experienced floor deck forming machine factory like Xinbo, with over ten years in precision engineering, reduces these risks. Their expertise ensures clients get a high quality floor deck roll forming machine tailored to their needs.

Xinbo’s average lead time for a floor deck machine is 45 to 60 days. This covers design, production, and inspections.

Yes, an advanced floor decking machine adjusts roller pressure to process coated steel without harming the surface.

Xinbo uses a triple-inspection process and hardened alloy rollers to improve wear resistance and ensure long-term reliability.

Xinbo offers PLC customization, including HMI in languages like English, Spanish, or Arabic, for easy operation.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→