Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→A metal roof panel roll forming machine is used to turn metal coils into strong roofing panels. These machines use rollers to shape the metal into specific designs, such as flat, wavy, or ribbed profiles. The process is called roll forming, and it helps create panels that are both strong and weather-resistant.

The machine has several key parts. First, there is a decoiler that holds the metal coil. Then, the input system moves the metal into the forming section. The forming rollers shape the metal, while the cutting unit trims the panels to the right length. After cutting, the panels are stacked and ready for use.

Automation makes these machines smart and easy to use. A PLC system controls everything. It helps the operator adjust the size, shape, and length of panels without stopping the machine. Hydraulic adjustments make switching between different roof types smooth and fast.

Multi-panel roofing machines are important because they can make many different types of roofing panels without needing a lot of time to change settings. For example, one machine can make corrugated panels for a warehouse and then switch to trapezoidal panels for a residential home. This saves time and helps builders stay on schedule.

These machines also work quickly. Some can produce panels at speeds up to 40 meters per minute. This high speed reduces wait times and increases productivity. Because of the precise cutting and shaping, there is less material waste, which saves money.

More industries are now looking for smart machines like the multi panel roofing machine. From construction and manufacturing to green buildings and solar panel systems, the need for flexible metal roof panel making machines keeps growing.

One of the best features of an auto-changing size roof panel machine is that it can adjust to different materials and sizes. It works with metal widths from 914 mm to 1250 mm and thicknesses from 0.3 mm to 0.8 mm. This makes it very flexible for many kinds of roofing needs.

Quick-change tooling makes the machine even more helpful. With modular rollers and hydraulic systems, it can switch between panel shapes without needing someone to do manual adjustments. This saves time and keeps production moving.

The machine also uses a PLC-controlled hydraulic cutting system. It trims panels with an accuracy of ±1 mm. This level of precision helps ensure that every panel fits perfectly on the roof.

The machine starts with a decoiler and input system. This part holds the metal coil and feeds it into the machine at a steady rate. Once inside, the forming section uses multiple rollers to shape the metal.

After forming, the cutting unit trims each panel to the correct length. The control panel is touchscreen-based, which lets operators make quick changes to the settings. These components work together to ensure the machine can handle a variety of panel types with ease.

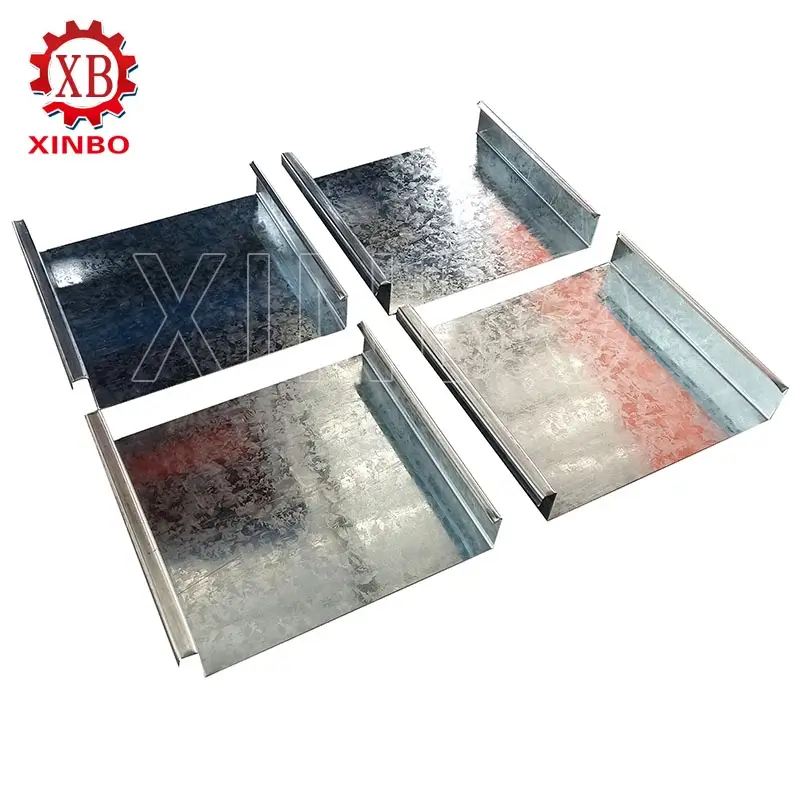

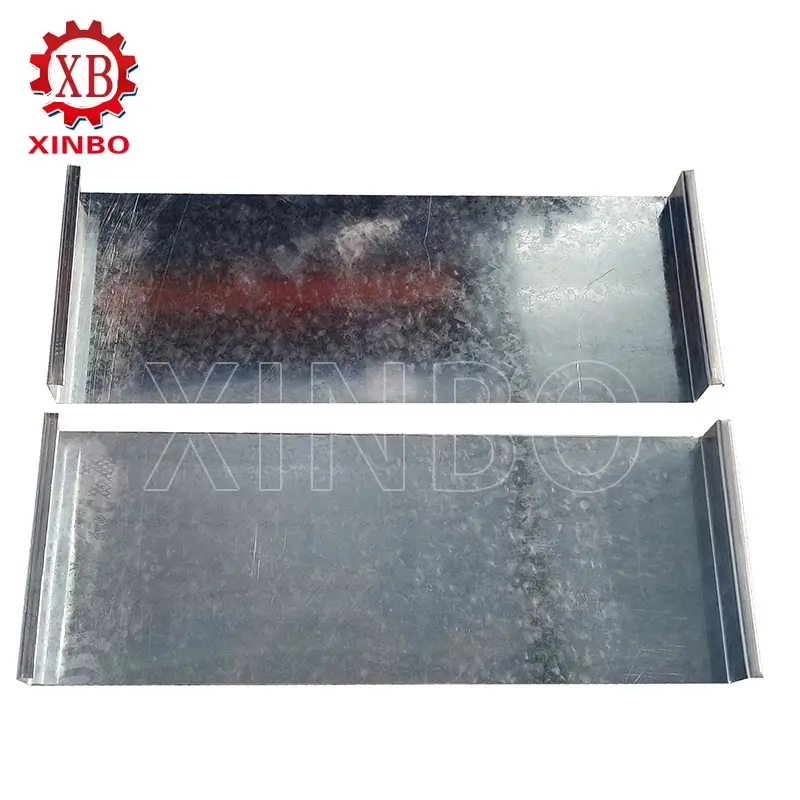

Xinbo offers a powerful customization service for its Auto-Changing Size Roof Panel Machine. Clients can request special profiles and choose materials like galvanized steel or aluminum. Xinbo’s engineers can also adjust the production speed to match your needs.

From the first CAD drawing to final machine testing, Xinbo works closely with customers to make sure the machine fits their project. Quality is a big part of the process. Each machine goes through three inspections and is made in ISO-certified factories.

If you’re looking for a flexible and high-quality metal roof panel roll forming machine, Xinbo’s custom solutions can help you get the perfect setup.

Commercial buildings such as warehouses and factories need strong roofs. The metal roof panels made by these machines are durable and leak-resistant. They are perfect for large spaces that need long-lasting protection.

Another common use is in solar panel installations. A multi panel roofing machine can make profiles that work well with solar systems. This supports clean energy goals and lowers utility costs for building owners.

In home construction, looks matter. A metal roof panel making machine can create panels in different colors and textures. This helps builders match modern styles and customer requests.

These machines also make lightweight panels. This is important for eco-friendly houses because lighter materials are easier to handle and transport. They also help lower the total cost of construction.

There are many special uses for these machines. In areas with hurricanes or strong storms, reinforced metal roof panels can add safety. These panels are made thicker and stronger to resist high winds.

In farming and agricultural projects, buildings like barns need metal panels that don’t rust. Machines that can produce corrosion-resistant panels are very useful for these types of structures.

Using a modern auto-changing size roof panel machine can save both time and money. Because it is automatic, you need fewer workers to run it. This lowers labor costs.

The production speed is much faster compared to older, manual machines. Some models can produce 8 to 12 meters of panel per minute. This means more output in less time, helping you finish jobs quicker.

These machines are also better for the environment. They use less energy and work with recyclable materials like steel and aluminum. Precision cutting creates less waste, so you don’t throw away as much metal.

By using an energy-efficient metal roof panel roll forming machine, you can build more and waste less. That’s good for business and for the planet.

Modern machines are built to last. They use strong materials like Cr12 steel for rollers and 45# forged shafts for extra strength. This helps them run longer without problems.

Maintenance is also easier. Parts are easy to reach, and some machines even support remote troubleshooting. This means that if something goes wrong, you can get help quickly and avoid delays.

When choosing a machine, think about how much you need to produce. High-speed machines are great for large jobs, while mid-range ones are better for smaller projects.

You should also look at material compatibility. Whether you’re using aluminum, steel, or coated metals, make sure the machine supports your choice.

Finally, consider how much space you have. Compact machines are perfect for smaller workshops or mobile job sites. They offer all the same features but take up less room.

Xinbo has more than 10 years of experience in metal forming technology. Since 2014, the company has helped customers from around the world with reliable machines.

All machines are built to fit standard shipping containers, making delivery fast and affordable. Xinbo also offers 24/7 technical support and a strong warranty, so you’re never alone if something goes wrong.

Auto-adjustable metal roof panel machines are changing how buildings are made. With one machine, you can switch between roof styles, adjust sizes, and make strong, high-quality panels.

Whether you are building a factory, a school, or a modern home, the Xinbo Auto-Changing Size Roof Panel Machine gives you the speed, accuracy, and flexibility you need to get the job done right.

Contact Xinbo today for a free consultation! Let our engineers help you design a machine that fits your exact needs. Don’t miss our limited-time offer: Mention this article and receive a 5% discount on your first order!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→