The Impact of Roll Forming Machine on Environmental Protection and Sustainable Development

In today’s global climate, there is a heightened consciousness surrounding environmental preservation. This has led to the integral aim of sustainable growth being incorporated into all sectors and industries. Within manufacturing specifically, roll forming machines are vital pieces of production equipment. Notably, their influence on conservation efforts and meaningful contributions toward sustainable development are significantly profound.

The impact of roll forming machine on environmental protection

Energy saving and emission reduction: Roll Forming Machines do not need to be heated during the production process and have low energy consumption, which contributes to energy saving and emission reduction. This not only reduces production costs, but also reduces the impact on the environment. At the same time, its efficient production method can also reduce the generation of waste during the production process and reduce the pollution to the environment.

High material utilization rate: Roll Forming Machine has a high material utilization rate in the production process, which can effectively reduce waste and save resources, in line with the concept of green environmental protection. This efficient utilization of resources not only reduces production costs, but also reduces the impact on the environment.

Reducing noise pollution: Compared with traditional stamping equipment, roll forming machines make less noise during the production process, which helps reduce noise pollution. This is also important for improving the working environment and protecting the health of employees.

Roll Forming Machines and Sustainable Development

Improve production efficiency: roll forming machine adopts continuous production method, high production efficiency, can meet the needs of mass production, help to realize the sustainable development of the economy. Efficient production not only meets the market demand, but also reduces production costs and improves the competitiveness of enterprises.

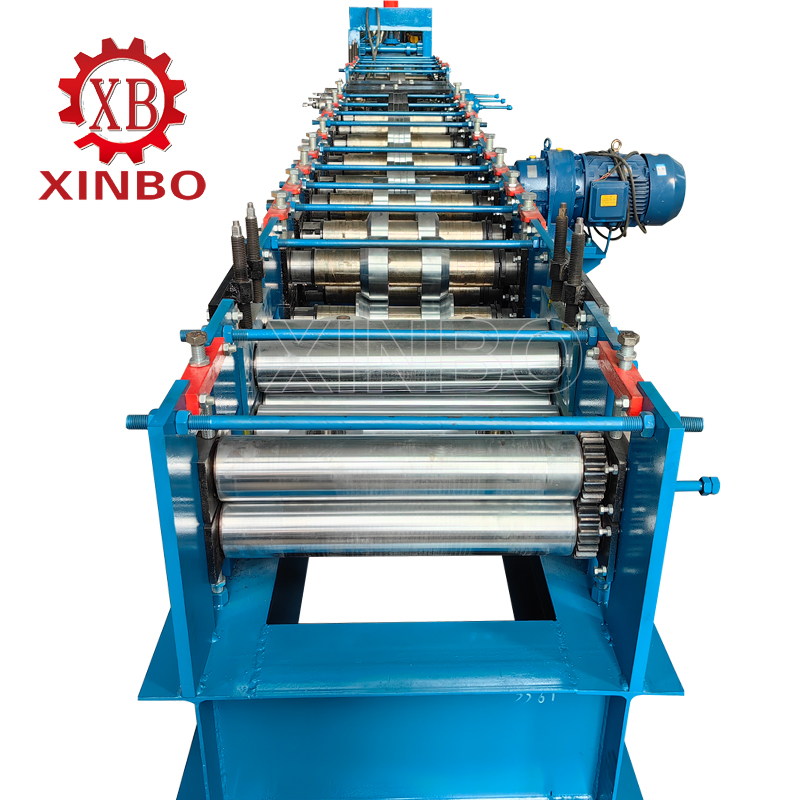

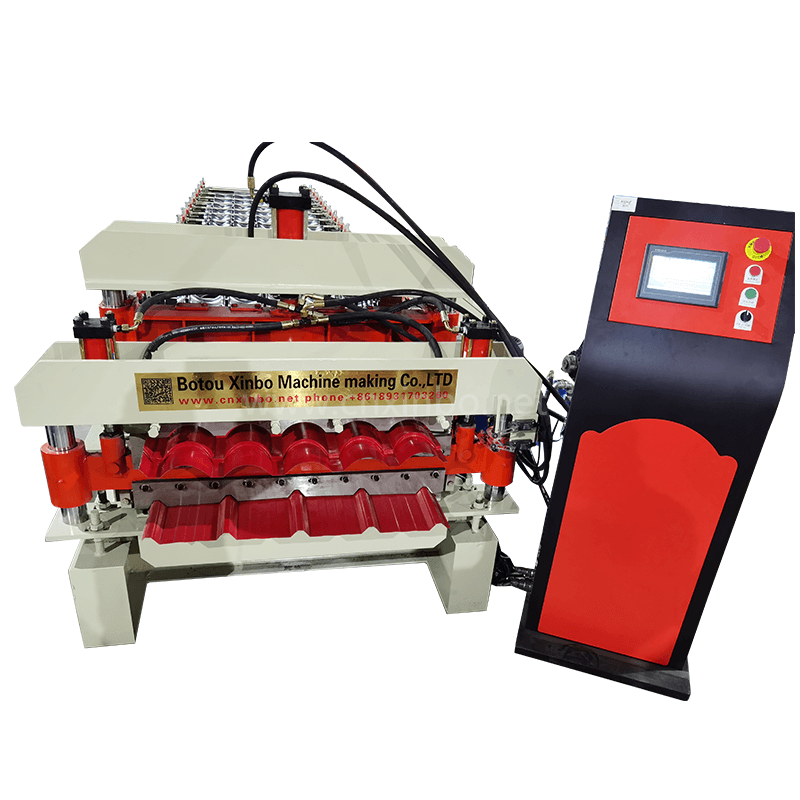

Xinbo’s roll forming machine adopts advanced PLC control system and hydraulic cutting technology, which can produce high quality products in a short time. This high efficiency production not only reduces energy consumption, but also reduces the impact on the environment.

Stable product quality: The high molding precision, stable product size and reliable quality of the roll forming machine help to improve the service life of the products and reduce the waste of resources, which is in line with the concept of sustainable development. High-quality products can not only meet consumer demand, but also reduce the frequency of product maintenance and replacement, reducing the waste of resources.

Strong flexibility: roll forming machines can produce products of various shapes and sizes as needed to meet various needs, which helps to realize the sustainable development of the society. This flexibility allows roll forming machines to adapt to changes in the market and meet the needs of different consumers.

Reducing waste: Xinbo’s roll forming machines can roll metal or other materials into specific shapes and sizes, which means it maximizes the use of raw materials and reduces waste generation. Additionally, many roll forming machines are equipped with a waste recycling system that recycles and reuses the waste generated during the manufacturing process, further reducing waste.

Trends in Roll Forming Machines

With the development of science and technology, the degree of intelligence and automation of roll forming machines will be further improved, production efficiency will be further improved, and the impact on the environment will be further reduced. At the same time, the green production concept of roll forming machine will also be more widely recognized and applied to promote the green development of manufacturing industry, to achieve sustainable development will play a greater role.

Intelligent: The future roll forming machine will be more intelligent and can realize automated production. Through the introduction of artificial intelligence and big data technology, intelligent control of the production process can be realized, improving production efficiency and reducing production costs.

Eco-friendly Manufacturing: The ecological efficiency of roll forming machinery is set for remarkable enhancements. By finessing the production process, significant gains can be made in terms of material utilization rates and waste reduction, ultimately culminating in eco-conscious manufacturing practices. This progressive approach lays a strong foundation for fostering environmentally responsible transformation within the broader manufacturing industry, steering it towards sustainable growth.

Market Segmentation: In response to an increasingly diverse market demand, roll-forming technology adapts by offering a wider spectrum of product variations tailored to myriad requirements. Such adaptability fuels innovative progression in the overall landscape of manufacturing while catering seamlessly to society’s evolving demands for sustainably developed products.

Conclusion

Rolling machinery has contributed significantly to environmental protection and sustainable development through its efficiency, accuracy, environmental protection and convenience. With scientific and technological developments, the application of the roll forming machinery will become more widespread, and its role in green growth of manufacturing industry and in realizing sustainable development will become more important so it should we find roll forming machinery very important To help more is to achieve sustainable development . At the same time, we also need to pay attention to the evolutionary nature of the roll machine, in order to make better use of this advanced manufacturing technology, to drive production encourage green development of the products to achieve sustainable development.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia