What Is a Ridge Cap Roll Forming Machine and How Does It Work?

Understanding the Basics of a Ridge Cap Roll Forming Machine

What Is a Ridge Cap Roll Forming Machine

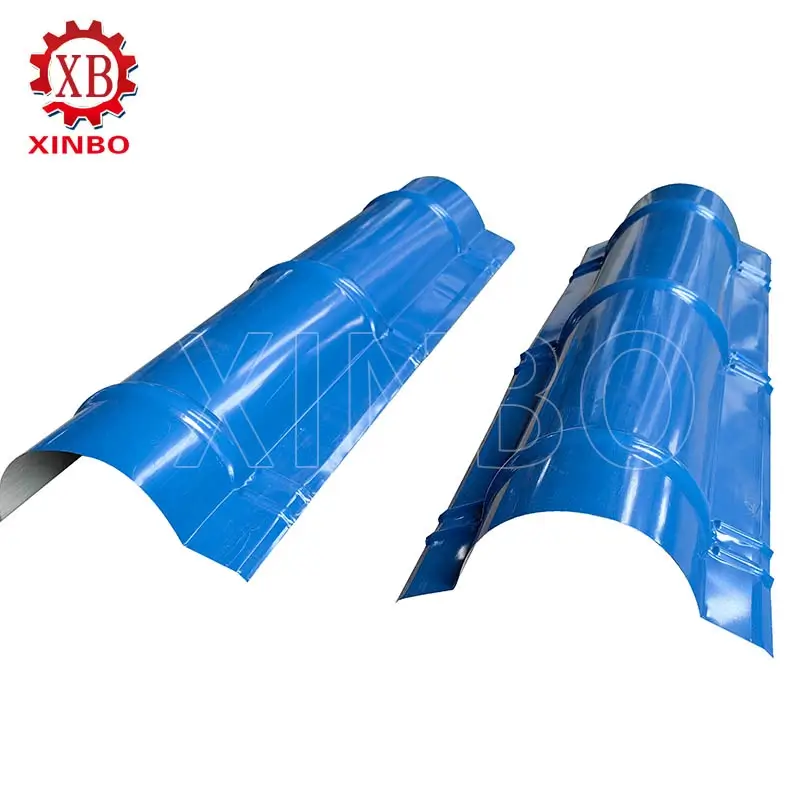

A Ridge Cap Roll Forming Machine is a special tool built to create ridge caps. These are key parts in roofing systems. The machine makes different shapes and styles of ridge caps. They act as the final touch where two roof sides join at the top. Ridge caps keep roofs waterproof. They stop rainwater from leaking into the building. Plus, they give a neat, weather-tight finish. Also, they improve the look of buildings by providing a smooth and tidy appearance.

The main goal of this machine is to make ridge cap production easier. It automates tasks like uncoiling, feeding, shaping, and cutting. This ensures great accuracy, consistency, and speed in making ridge caps. These caps are designed to match specific roof styles.

Key Components of a Ridge Cap Roll Forming Machine

A Ridge Cap Roll Forming Machine has several important parts that work together to produce top-quality items:

Decoiler: This part holds and unrolls the raw material, often pre-painted galvanized steel or aluminum, into the machine.

Feeding Platform: It directs the material into the shaping section.

Roll Forming Unit: The main part where rollers mold the material into the desired ridge cap shape. The rollers are usually made from strong steel with chrome coating for toughness.

Cutting System: It uses hydraulic or mechanical blades to slice the shaped material into set lengths.

Control System (PLC): A programmable logic controller ensures exact operation. It controls speed, size, and other settings.

Hydraulic Station: It powers the cutting system and other hydraulic parts.

Run-Out Table: It gathers finished ridge caps for easy handling and packing.

Machines like those from Xinbo can be adjusted to meet customer needs. This ensures they work with various roof shapes while keeping speed and quality.

The Functionality of a Ridge Cap Roll Forming Machine

The Working Principle Behind the Machine

The Ridge Cap Roll Forming Machine works on a simple but very effective idea:

Raw materials in coil form are placed on the decoiler.

The material moves through guiding rollers. These keep it aligned properly.

It passes through several roller stations in the roll forming unit. Here, it is slowly shaped into the desired form.

After shaping, the material reaches the cutting section. It is cut to exact lengths based on settings in the PLC control system.

This automated process reduces human work. It also ensures steady product quality.

The Step-by-Step Process of Ridge Cap Formation

Material Loading: The coil is set on the decoiler. It is prepared for feeding.

Guiding: The feeding platform aligns the material correctly.

Roll Forming: A series of rollers gradually shapes the material into a ridge cap form.

Cutting: Hydraulic or mechanical cutters trim the material to set lengths. They do this without damaging edges.

Collection: Finished ridge caps are gathered on a run-out table. They are ready for checking and packing.

Machines like Xinbo’s ensure every step is done accurately. Their advanced PLC systems guarantee not only speed but also high-quality results. These are suitable for modern building needs.

Applications of Ridge Cap Roll Forming Machines

Use in Roofing Systems

Ridge caps made by these machines are vital for roofing systems. They are used in both homes and businesses. They seal joints at roof ridges to block water leaks. They also add strength to roofs. Without well-placed ridge caps, rainwater could enter weak spots like chimneys or higher roof tiles.

These machines can make standard ridge caps with flat legs. They can also create custom shapes that fit trapezoidal roofing sheets. This avoids extra cuts during installation. As a result, it boosts work speed.

Role in Construction and Building Projects

In building projects, Ridge Cap Roll Forming Machines help finish work faster. They provide ready-to-use parts designed for specific styles. Their flexibility lets them create shapes for different building designs. They also stay strong in harsh weather.

Xinbo’s machines offer quick customization options. They have fair prices due to in-house CNC machining. They also deliver fast. These features are key for meeting project deadlines. Moreover, these machines support green building practices. They reduce waste during production. They also use recyclable materials like steel or aluminum coils.

For experts in construction or manufacturing looking for dependable solutions, Xinbo’s Ridge Cap Roll Forming Machines are a great choice. Their new technology and adjustable features meet various needs. Contact Xinbo today to learn how their advanced tools can improve your projects!

Advantages of Using a Ridge Cap Roll Forming Machine

Efficiency in Production

A Ridge Cap Roll Forming Machine provides unmatched speed in production. It automates steps like uncoiling, feeding, shaping, and cutting. This greatly reduces manual work. It also speeds up manufacturing. These machines can shape materials at 15-20 meters per minute. So, they produce large amounts of ridge caps quickly. They maintain quality, too. This makes them perfect for building projects with tight schedules.

The automated system also cuts down on mistakes. It ensures all ridge caps are uniform. For example, Xinbo’s machines have advanced PLC control systems. These allow precise changes to sizes and shapes. This ensures they work with various roof designs while keeping high standards.

Precision and Consistency in Output

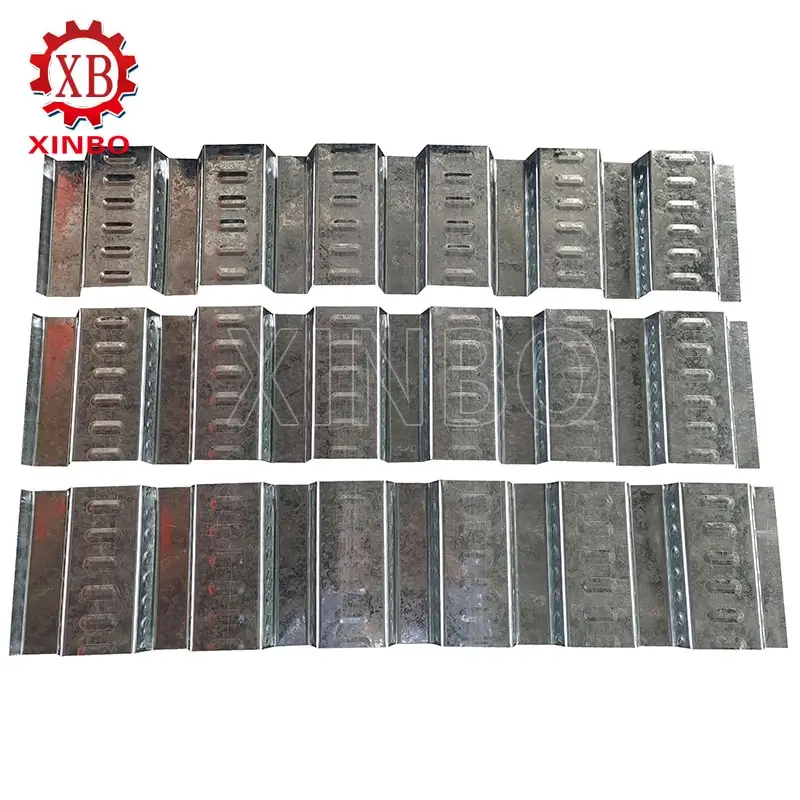

Accuracy is a key feature of Ridge Cap Roll Forming Machines. The rollers, often made from strong steel and coated with chrome, shape each ridge cap to exact measurements. The cutting systems, whether hydraulic or mechanical, trim materials to set lengths with great precision.

Machines like Xinbo’s go through strict quality checks three times before shipping. This ensures every part works perfectly. This focus on accuracy guarantees consistent results. It makes these machines essential for projects needing high-quality roofing parts.

Factors to Consider When Choosing a Ridge Cap Roll Forming Machine

Material Compatibility and Durability

When picking a Ridge Cap Roll Forming Machine, consider its ability to work with different materials. Most machines handle pre-painted galvanized steel (PPGI) or aluminum coils. These are common in roofing systems. For instance, Xinbo’s machines support materials from 0.3mm to 0.8mm thick. This offers flexibility for various project needs.

Strength is another key factor. Machines built with tough materials, like No.45 steel for rollers and CR12 mold steel for cutters, last longer. They resist wear and tear. These features improve the machine’s lifespan. They also ensure steady performance over time.

Production Capacity and Speed

The production ability of a Ridge Cap Roll Forming Machine affects its fit for specific projects. High-speed machines that produce 15-20 meters per minute are great for large-scale work. Time efficiency is critical here. Also, features like non-stop cutting systems boost productivity. They eliminate pauses between tasks.

Xinbo’s machines offer adjustable options to meet different production needs. They suit both small manufacturers and large construction companies.

Maintenance and Care for Ridge Cap Roll Forming Machines

Routine Maintenance Practices

Regular upkeep is vital to keep Ridge Cap Roll Forming Machines working well. Lubricating moving parts like rollers and cutting frames reduces friction. It also prevents wear over time. Checking parts like the hydraulic station, PLC system, and decoiler regularly helps spot issues early.

Machines like Xinbo’s need little maintenance. Their strong build and user-friendly design help. However, following routine upkeep schedules can extend their lifespan. It also ensures steady performance.

Troubleshooting Common Issues

Even with their dependability, Ridge Cap Roll Forming Machines may face problems. These include misaligned rollers or uneven cuts. Fixing these issues quickly is important to avoid production delays.

Common troubleshooting steps include:

Checking Roller Alignment: Misaligned rollers can cause uneven shaping of ridge caps.

Inspecting the Cutting System: Dull or damaged blades may lead to imprecise cuts.

Monitoring the PLC System: Ensuring the programmable logic controller works correctly keeps sizes and shapes accurate.

Xinbo’s support team offers technical help to fix issues quickly. This minimizes downtime and keeps production steady.

Ridge Cap Roll Forming Machines are valuable tools for making high-quality roofing parts efficiently. With features like advanced PLC systems, customizable designs, and fair pricing, Xinbo’s machines are a reliable choice for construction experts. Contact Xinbo today to see how their innovative tools can improve your production while meeting your project needs!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia