Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→A metal poultry feeding trough roll forming machine is an advanced piece of equipment designed to manufacture high-quality feeding troughs for poultry farming. These machines streamline the production process, ensuring precision and consistency in shape, size, and material thickness. Feeding troughs produced by this machine are essential components in poultry farming as they provide a durable and hygienic means of feeding livestock. Roll forming machines are widely used in various industries for the production of high-quality, cost-effective metal products.

The machine is equipped with innovative technology to meet specific customer requirements. Our roll forming machines are designed and made according to customers’ requests. Its smart structure ensures efficient functionality while maintaining ease of operation. Additionally, it boasts a reasonable design that optimizes material usage while minimizing waste. The ability to produce customized designs further enhances its versatility.

The machine’s frame is tough. It stays steady while working. Its smart design fits different metal sheet sizes and thicknesses. This lets makers create feeding troughs for all kinds of poultry farm needs.

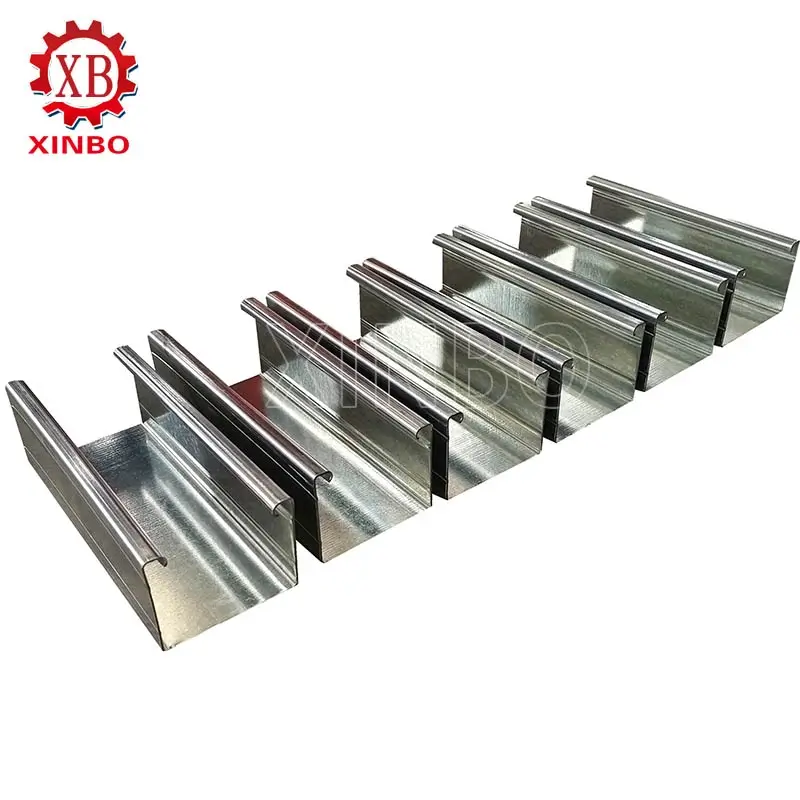

Rollers are a big deal in the roll forming machine. These carefully made rollers shape metal sheets into feeding trough shapes. Roll forming machines make steady, exact shapes, sizes, and thicknesses of metal sheets. The rollers keep everything even and keep the material strong.

The cutting system is another key part. It uses new tech to slice metal sheets into the right lengths. This automatic setup makes work faster. It cuts down on handwork. Each trough meets exact sizes needed.

The work starts with putting raw metal sheets into the machine. You can do this by hand or use an automatic feeder. The feeding platform makes sure materials slide in smoothly. It stops damage or bending.

Once the metal is in, it goes through sets of rollers. These slowly shape it into a feeding trough. Roll forming machines make steady, exact shapes, sizes, and thicknesses of metal sheets. This step bends the metal at room temperature. It avoids heat messing up the final trough.

After the metal gets its trough shape, an automatic cutter slices it to the right length. The work flow goes like this: Manual decoiler—-Feeding Platform—-Main Roll Forming Machine—-Automatic Cutting System—Hydraulic Station—Computer Control Box—-Finished Panel Receiving Table. This makes every piece the same size. It’s ready for poultry farms.

This full process shows how a metal poultry feeding trough roll forming machine mixes speed with exactness. It meets what the industry needs.

The metal poultry feeding trough roll forming machine is super important. It makes key gear for poultry farming. Feeding troughs are a big part of farm setups. This machine makes them with care and sameness. Roll forming machines are used in many fields to create good, cheap metal items. The machine handles different metal sheet sizes and thicknesses. This lets makers meet all kinds of poultry farm needs.

This machine makes sure troughs are tough and clean. It meets strict rules for animal health. By doing the work automatically, it skips mistakes that happen with hand-made troughs. Plus, it can make special designs. This helps meet the needs of modern poultry farms.

Big farms need to work fast and well. The metal poultry feeding trough roll forming machine helps a lot. Its automatic setup boosts how much it can make. Roll forming machines make steady, exact shapes, sizes, and thicknesses of metal sheets.

For huge farms with lots of animals, this machine keeps feeding gear coming. The troughs it makes last a long time. This cuts down on replacing them. It saves money and makes farms run smoother.

One great thing about this machine is how quick it works. Its automatic setup lets makers churn out tons of feeding troughs fast. Roll forming machines can make a big pile of metal parts in a short time. This meets big orders and cuts wait times for delivery.

The machine uses new tech for smooth work. From feeding metal to cutting and shaping, it runs without hiccups. This keeps downtime low and work high.

Saving cash is another big plus. By automating work, the machine cuts down on worker costs. It still makes a lot of troughs. Roll forming machines make top-notch metal parts cheaper than other ways. Also, it uses materials smartly. This reduces waste and saves more money.

For makers serving big farms, these savings mean lower prices. This makes their troughs more appealing to buyers.

The troughs from this machine are tough and spot-on. The rollers keep sizes even and the material strong. Roll forming machines can make tricky shapes with tight fits. This exactness is key for troughs that fit perfectly in poultry farm setups.

The machine itself is built to last. It works reliably for a long time. Its sharp cutting system makes sure every trough is the right length. This avoids problems that could mess up how troughs work.

Xinbo is a top name in making great roll forming machines. Started in 2014, Xinbo is known for new ideas and expert skills.

Xinbo makes roll forming machines to fit what customers need. Our skilled design team builds the machine totally based on customer wants.

Xinbo’s metal poultry feeding trough roll forming machine shows their drive for greatness. It has a clever build and smart design. These make it work well and waste less material. Xinbo also gives full service. This covers designing, putting together, setting up, and helping after the sale.

Xinbo reaches all over the world. They send machines to Europe, the Middle East, Africa, America, South America, and more. Our machines have been exported to Europe, Middle East, Africa, America… This makes Xinbo a trusted friend for businesses needing solid roll forming solutions. Contact Xinbo for your machine need now.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→