Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

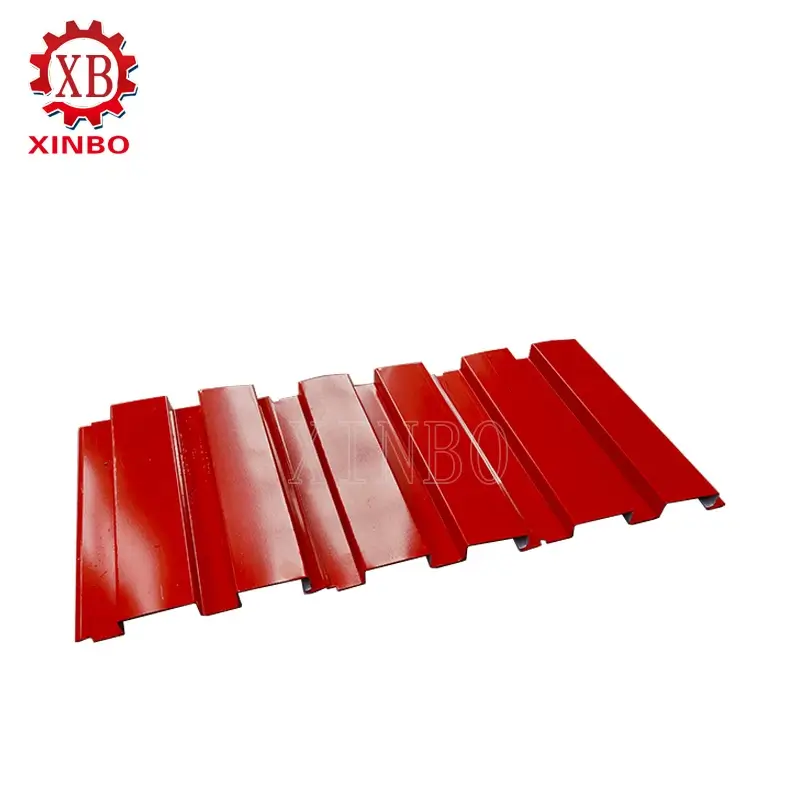

VIEW MORE→A decorative wall panel roll forming machine is a continuous cold-forming production line that converts flat metal coil into finished architectural panels with complex aesthetic profiles. The core principle is progressive bending: the strip passes through 18–30 pairs of contour rollers, each performing only 5°–15° of deformation. This gradual process prevents coating cracks, spring-back, and internal stress that would destroy the decorative finish.

Modern decorative panels CNC roll forming machines integrate servo-driven length measurement, flying cut-off, and recipe-based PLC control, achieving dimensional tolerances of ±0.3 mm and surface quality suitable for Class A architectural façades.

Capacity: 5–15 tons (8–10 tons most common) Type: Hydraulic mandrel expansion + brake or active servo decoiling Features required for decorative work:

9–13 rollers (typically 11) with 4-high or 6-high configuration Individual servo adjustment of upper rollers (±0.01 mm) Edge-wave and center-buckle removal capability up to 1.5 mm in 0.5 mm material Anti-scratch PU or nylon coated pinch rolls for glossy finishes

Shaft diameter: Ø70–Ø90 mm (Ø80 mm is the sweet spot for decorative precision) Roller material: Cr12MoV / SKD11 / D2, vacuum quenched HRC 59–61, finish ground and PVD or hard-chrome coated Housing: 30–40 mm welded & annealed steel plate, CNC-machined parallelism ≤0.02 mm Stand design options:

Hydraulic stop-cut shear → unacceptable for decorative pre-painted material (causes edge deformation) Servo flying saw with twin-blade system → current industry standard (±0.5 mm at 25 m/min, zero surface damage) Flying die-cut for perforated decorative patterns or complex end notches

PLC: Siemens S7-1200/1500, Mitsubishi Q-series, or Beckhoff HMI: 12–15 inch color touchscreen with recipe storage for 200+ profiles Functions you should demand:

|

Parameter |

Minimum Acceptable |

Recommended for Premium Decorative Work |

|

Thickness range |

0.3–0.8 mm |

0.25–1.2 mm |

|

Forming speed |

12–18 m/min |

18–28 m/min (servo line) |

|

Length tolerance |

±1.0 mm |

±0.3–0.5 mm |

|

Profile changeover time |

<2 hours |

10–20 minutes (cassette) |

|

Roller life before regrinding |

800,000 m |

1.5–3 million m |

|

Frame plate thickness |

25 mm |

35–40 mm stress-relieved |

|

Shaft diameter |

Ø65 mm |

Ø80–90 mm |

Best results achieved with:

Avoid high-strength steel >550 MPa unless the machine has reinforced stands and slow-speed mode.

Daily: clean metal dust, check oil levels Weekly: lubricate all grease points, inspect roller gaps Monthly: laser alignment check of all stands (±0.02 mm) Quarterly: hydraulic oil analysis + filter replacement Annually: full geometry measurement with laser tracker + roller regrinding if needed

Q1: What is the real difference between a roofing roll forming machine and a decorative wall panel roll forming machine?

A: Decorative machines require 2–3 times tighter tolerances, surface-protection systems, servo flying cut-off, and often embossing stations. Roofing machines prioritize speed and water-tightness; decorative machines prioritize aesthetics and coating integrity.

Q2: Can one decorative wall panel roll forming machine produce both flat smooth panels and deep grain textures?

A: Yes — with quick-change cassettes or duplex configuration, changeover takes 10–20 minutes.

Q3: What speed should I expect without damaging pre-painted coatings?

A: 15–25 m/min is the safe zone for most decorative profiles. Above 28 m/min requires special low-friction rollers and coating tests.

Q4: Is servo flying cut-off really necessary?

A: For any pre-painted or textured decorative panel, yes. Hydraulic stop-cut systems deform the profile and scratch the coating.

Q5: How long do rollers last on a high-quality decorative panels CNC roll forming machine?

A: 1.5–3 million linear meters before first regrinding when using PVD-coated Cr12MoV/D2 and proper lubrication.

Q6: Can these machines produce perforated decorative panels?

A: Yes — with high-speed servo punch press before forming or flying die-cut station after forming.

Q7: What is the typical power consumption?

A: 18–35 kW depending on line speed and number of servo axes (much lower than old hydraulic lines).

XINBO is a specialist manufacturer of decorative wall panel roll forming machines, wall decorative panel roll forming machines, decoration panel roll forming machines, and decorative panels CNC roll forming machines. Since its founding in 2014, XINBO has focused on customized machine design, tooling, process optimization, and rigorous testing — delivering reliable, flexible systems capable of producing high-precision decorative metal panels. Their machines are used in architectural façades, interior cladding, and decorative structure manufacturing.

For a tailored quote, technical drawings, or a sample panel production using your own material and profile, contact XINBO on their website. Request a factory sample run with your coil specification, so you can verify surface finish, profile accuracy, and cycle speed before committing to a purchase.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→