Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

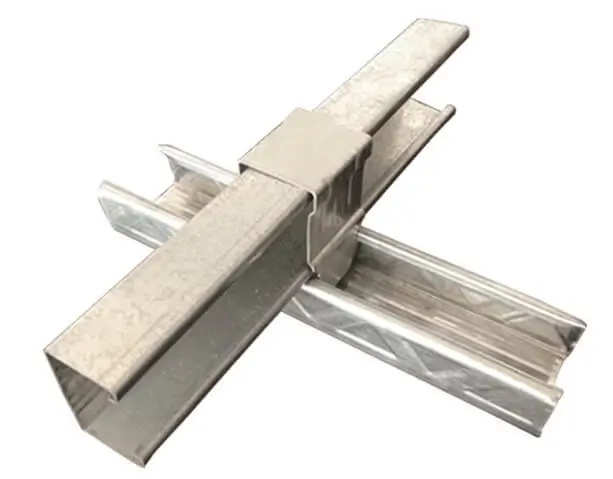

VIEW MORE→Furring clips are key pieces in construction. They make a space between surfaces and give support for ceilings, walls, and other structures. These clips are usually made from metal. They act as a mounting base for adding things like drywall or acoustic panels. Their design keeps structures strong while leaving room for insulation, wiring, or mechanical systems behind the finished surface.

Furring clips are used a lot in homes and businesses. In homes, they create a gap between the ceiling and drywall. This allows insulation and space for electrical wiring. In big commercial or industrial projects, they hold up suspended ceilings and partition walls. They help keep things aligned and spread out weight. They’re also used in special jobs like soundproofing, HVAC setups, and fire-rated systems.

A furring clip roll forming machine bends a metal strip bit by bit. Flat metal coils go into the machine. They pass through many roller stations. These rollers slowly shape the metal into exact clip shapes. This steady process makes clips fast with little material waste.

The furring clip roll forming machine has several main parts:

Furring clip roll forming machines can make different shapes based on project needs. These include hat channels, Z-clips, U-shaped brackets, and custom designs for special sound or structural needs.

Besides regular uses, furring clips work in special areas like soundproofing, fireproofing, and HVAC setups. The flexibility of roll forming machines makes them great for producing lots of identical clips for different places, like homes, office buildings, shopping centers, hospitals, and schools.

Roll forming machines work fast. They can make tons of furring clips quickly. This cuts down wait times and helps finish projects sooner.

The automatic process of roll forming makes sure every clip is made just right. It avoids mistakes and keeps all clips the same.

Roll forming machines save material and cut labor costs. This makes them a cheap way to make furring clips. It helps lower overall building costs while keeping quality high.

These machines can be tweaked to make clips in different sizes and shapes. This fits many building needs. Operators can switch setups fast without long breaks.

Roll forming machines can work with punching or embossing tools. These add holes or textured surfaces. This setup combines many steps into one smooth process, making work faster.

Furring clip roll forming machines are made with tough materials. They can handle constant work in industrial settings. Regular care, like oiling rollers or checking cutting blades, keeps them running well. With good care, these machines work reliably for years with little downtime.

Key things to think about include:

Roll forming uses materials wisely and can make clips on-site. This cuts down on shipping and emissions. It also makes less scrap than stamping methods. This supports greener building practices.

XinBo is a manufacturer based in China since 2014. Our team of expert designers, producers, and workers ensures quality. XinBo makes custom roll forming equipment that meets global standards, including CE certification. We promise high-quality machines and new technology, offering OEM and ODM services worldwide, including Europe, UK, Canada, and more.

Each machine is checked three times before shipping. We design and use CNC machining ourselves. This ensures fast delivery of machines that match your needs. Contact XinBo today.

A: Usually galvanized steel or aluminum coils are used. They’re tough and resist rust.

A: Yes. Most modern machines have adjustable tools. They allow quick switches between clip shapes.

A: Basic training is a good idea. But most systems have easy-to-use control panels that make operation simple.

A: Depending on the setup, hundreds or thousands of clips can be made per hour. This is thanks to the machine’s steady process.

A: You get a full setup with uncoiler, main roll former unit, hydraulic cutter system, and complete after-sales support, including remote help if needed.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→