Window Screen Frame Roll Forming Machine for Aluminum & Steel Frames

The window screen frame roll form machine serves as a key part of today’s manufacturing in the fenestration industry. It allows efficient production of strong frames for insect screens. In the same way, the Roll forming machine for aluminum frame of screen window provides accuracy and steady results. It changes flat metal coils into top-quality profiles that work well for homes and businesses. These machines make the whole process simpler. They create light but tough frames that hold insect mesh firmly and still look good.

This detailed guide looks at the technology, how they work, the benefits, and important points about these special machines. It gives useful information for manufacturers, fabricators, and people in the industry.

Understanding the Basics of Window Screen Frame Roll Forming Machines

Window screen frames are important parts. They hold fine mesh to block insects while letting air pass through. In the past, people made them mostly by extrusion. Now, more and more production uses roll forming because it is efficient and saves money.

A window screen frame roll form machine uses a row of carefully designed rollers. These rollers slowly bend flat metal strips, usually aluminum or steel coils, into the needed shape. This cold-forming method gives even cross-sections. It does not heat the material, so the strength and surface stay good.

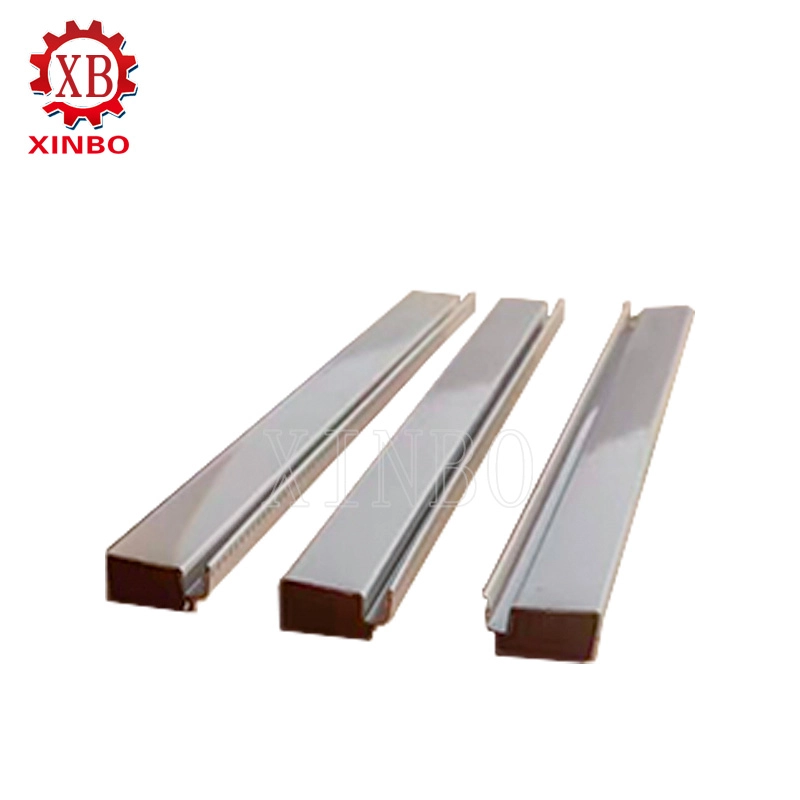

The Roll forming machine for aluminum frame of screen window does very well at making profiles with built-in details. These include spline grooves to hold mesh, lips for inset fitting, or stronger edges for extra durability. Common types are box frames (plain rectangular) and lip frames (with a sealing edge). They often come in thicknesses from 0.4mm to 0.6mm.

Key Components of the Machine

-

Uncoiler: Holds and feeds the metal coil in a smooth way, often with automatic tension control.

-

Leveler/Straightener: Takes away the curve from the coil so forming stays accurate.

-

Roll Stations: Usually 18–25 stations. Each one has custom rollers that shape the metal step by step.

-

Cutting System: Uses hydraulic or flying shear to cut lengths exactly.

-

Control System: PLC-based with touchscreen for setting profiles and speeds.

How a Window Screen Frame Roll Forming Machine Works

The operation of a window screen frame roll form machine follows a steady and automatic flow. This keeps high accuracy and cuts waste to a minimum.

First, load a pre-painted or mill-finished aluminum or steel coil onto the uncoiler. The strip moves into the entry guide. There it gets leveled and lined up properly.

As the material moves through the roll stations, each set of rollers adds gentle pressure. This bends it little by little. Such slow bending prevents cracks and keeps the material strong. For example, early stations form the main channel. Later ones add the spline groove and edge crimps.

Many advanced Roll forming machine for aluminum frame of screen window models include inline punching for holes or notches. They also have pre-bowing to keep tension and hydraulic cutting for exact lengths. The finished profile comes out of the machine. It is ready for assembly into full screens.

Typical Production Process

-

Material Feeding → Coil uncoiling and straightening.

-

Roll Forming → Progressive bending across multiple stations.

-

Inline Processing → Punching, notching, or embossing as needed.

-

Cutting → Precise length cutting with minimal burrs.

-

Output → Stacked profiles ready for screen assembly.

Modern machines reach speeds up to 30–50 meters per minute. Some top models go even faster for big production runs.

Materials and Profiles in Window Screen Frame Production

Aluminum is the top choice. It resists corrosion well, stays light, and forms easily. Steel is chosen when extra strength is needed. It usually gets protective coatings.

Profiles change based on use:

-

Standard Box Frame — Simple rectangular for everyday use.

-

Lip Frame — Has a sticking-out edge for better sealing.

-

Knife Edge Frame — Thin design for inset installations.

The window screen frame roll form machine works with coils from 50mm to 300mm wide. It makes profiles that meet industry rules for strength and fit.

Advantages of Aluminum vs. Steel Frames

Aluminum gives great weather resistance and low weight. It suits residential screens perfectly. Steel offers better stiffness for bigger or heavy-duty uses. However, it needs good coating to stop rust.

Key Features and Benefits of Modern Roll Forming Machines

Current window screen frame roll form machine designs focus on automation and accuracy.

-

High-Speed Production — Cuts labor needs and boosts output.

-

Precision Tolerances — Steady sizes make assembly simple.

-

Material Efficiency — Less scrap than extrusion.

-

Customization — Fast switch to different profiles.

-

Automation — PLC controls, servo drives, and touchscreens.

The Roll forming machine for aluminum frame of screen window often comes with safety items like guards and emergency stops. It also has energy-saving motors.

Enhancing Productivity with Advanced Features

Many machines allow batch production. They program several profile lengths for kit assembly. Computer-controlled pre-bowing makes mesh tension better. Automatic sequencing reduces mistakes.

Applications and Industry Impact

These machines help window and door fabricators, screen manufacturers, and suppliers. When companies produce in-house, they lower costs and shorten lead times.

Roll-formed frames are used in:

-

Residential window screens

-

Patio and porch enclosures

-

Solar screens for energy efficiency

-

Commercial and industrial applications

The window screen frame roll form machine handles high-volume output. It lets companies respond fast to market needs.

Sustainability Considerations

Roll forming uses less energy than extrusion and creates less waste. Aluminum and steel are recyclable, which makes them even better for the environment.

Maintenance and Best Practices

Regular maintenance keeps the machine lasting long and running well.

-

Daily Checks — Lubricate rollers and check alignments.

-

Periodic Inspections — Clean stations and look for roller wear.

-

Training — Operators need to know controls and how to fix problems.

Good care makes the machine last longer and keeps quality high.

Common Troubleshooting Tips

-

Profile distortion → Adjust roller pressure or alignment.

-

Material slippage → Check uncoiler tension.

-

Inaccurate lengths → Calibrate cutting system.

FAQ

What is the difference between roll forming and extrusion for screen frames?

Roll forming uses cold bending on coils for cheap, high-volume production. Extrusion pushes heated metal through a die for complex shapes but costs more.

Can a window screen frame roll form machine produce both aluminum and steel frames?

Yes, most machines handle both. Adjustments may be needed for thickness and material properties.

How fast can a Roll forming machine for aluminum frame of screen window operate?

Typical speeds range from 15–50 meters per minute. It depends on model and profile complexity.

What maintenance is required for these machines?

Regular lubrication, roller checks, and cleaning stop downtime and keep precision.

Are roll-formed screen frames as strong as extruded ones?

Roll-formed frames are light and enough for most uses. Work-hardening makes them stronger. Extruded frames fit heavier-duty needs better.

Ready to Elevate Your Screen Frame Production?

Investing in a high-quality Window Screen Frame Roll Forming Machine can change manufacturing efficiency. It lowers costs and provides better products. Contact XINBO today to learn how our advanced window screen frame roll form machine and Roll forming machine for aluminum frame of screen window can fit your production needs. With proven skill in precision engineering and reliable support, XINBO is your trusted partner for new roll forming solutions. Reach out now to talk about custom setups made for your operations!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia